Inkjet printing material for bleeding and eduction resistance and high precision

An inkjet material, high-precision technology, applied in the direction of textile, lamination, fabric, etc., can solve the problems not involved in the production of anti-dialysis inkjet materials, achieve remarkable stability, improve processing speed, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] An anti-dialysis high-precision inkjet material prepared by the following method:

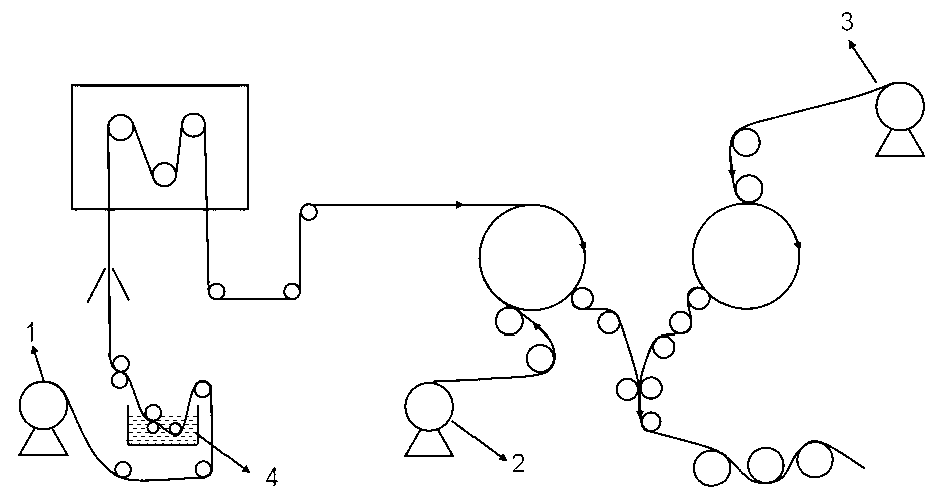

[0032] (1) Using high-strength and low-shrinkage polyester yarn as the raw material, the base fabric after warping, weaving and splitting and winding is used as the skeleton material; (2) The skeleton material in step (1) is dipped, dried and pre-shaped , using double-sided hot-melt lamination of PVC film and then embossing, cooling, shaping and trimming to obtain anti-dialysis high-precision inkjet materials. The preparation process of step (2) is as figure 1 As shown, 1 is the skeleton material, 2 is the base film, 3 is the mask, and 4 is the water-based polyurethane glue.

[0033] The specification of the high-strength and low-shrinkage polyester yarn is 1000d, and the fabric density of the skeleton material is 18×12 threads / inch.

[0034] In the hot-melt lamination, after preheating the base film and the facial mask, the base film is first bonded, and then the facial mask is bonded...

Embodiment 2

[0040] An anti-dialysis high-precision inkjet material prepared by the following method:

[0041] (1) Using high-strength and low-shrinkage polyester yarn as the raw material, the base fabric after warping, weaving and splitting and winding is used as the skeleton material; (2) The skeleton material in step (1) is dipped, dried and pre-shaped , using double-sided hot-melt lamination of PVC film and then embossing, cooling, shaping and trimming to obtain anti-dialysis high-precision inkjet materials. The preparation process of step (2) is as figure 1 As shown, 1 is the skeleton material, 2 is the base film, 3 is the mask, and 4 is the water-based polyurethane glue.

[0042] The specification of the high-strength and low-shrinkage polyester yarn is 500d, and the fabric density of the skeleton material is 18×18 threads / inch.

[0043] In the hot-melt lamination, after preheating the base film and the facial mask, the base film is first bonded, and then the facial mask is bonded....

PUM

| Property | Measurement | Unit |

|---|---|---|

| preheating temperature | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com