Manufacturing method for elevator sill

A manufacturing method and sill technology, applied to metal processing equipment, etc., can solve problems such as easy loosening of the sill body and bracket parts, blocked door opening and closing, and inconvenient disassembly, so as to achieve a beautiful, simple and elegant appearance, and solve low-strength problems , rich model effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

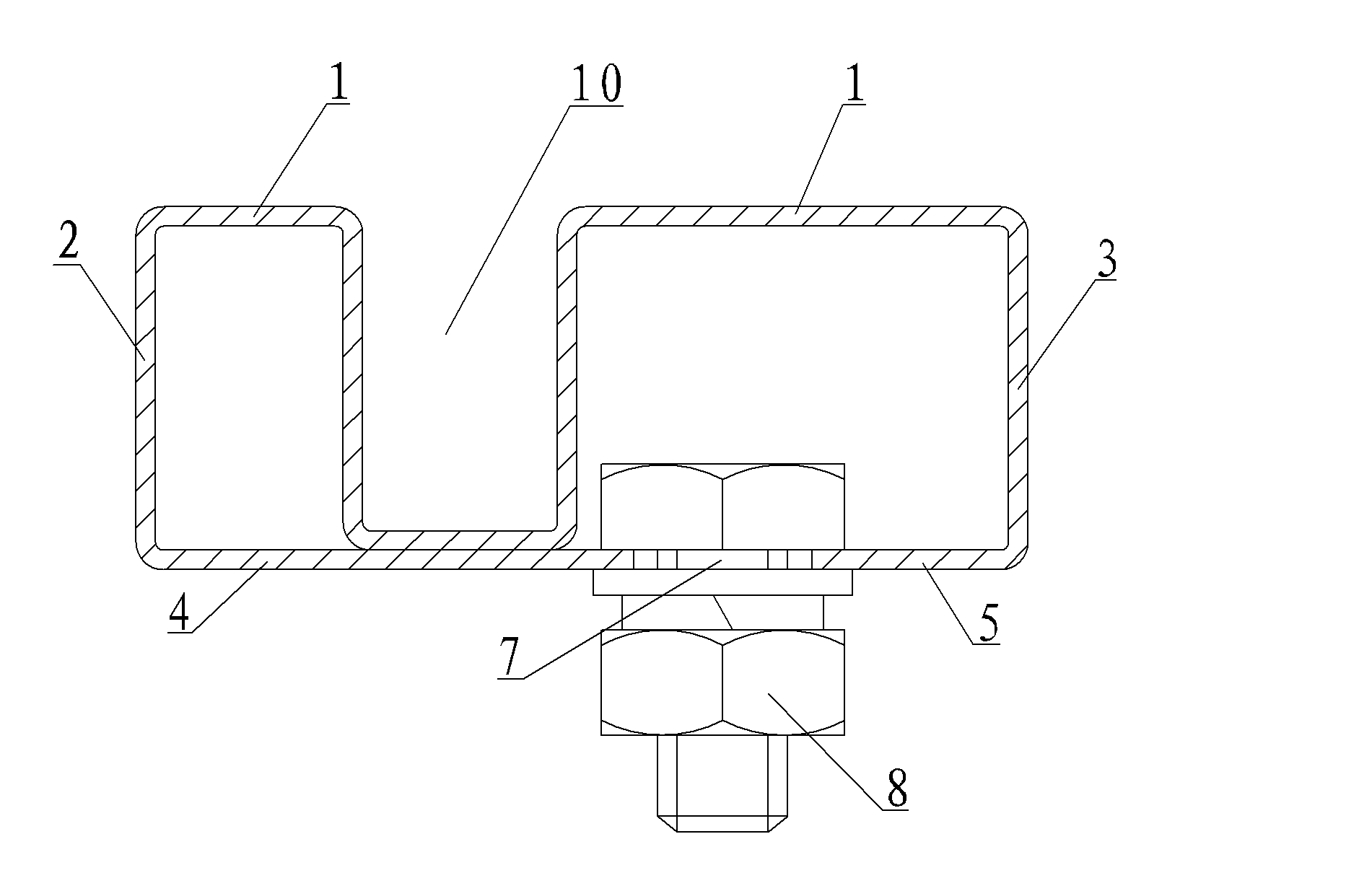

[0023] This embodiment provides a figure 1 The manufacturing method of the elevator sill shown, it comprises the following steps:

[0024] (1) Using stainless steel strip material, the elevator door chute 10 is formed by rolling in the middle, which is the sill body 1;

[0025] (2) By cold bending and rolling, one side of the sill body 1 is bent longitudinally downward to form the first side arm 2, and the lower end of the first side arm 2 is further bent inward and extended horizontally to form the first side arm 2. The bottom bracket 4, the first bottom bracket 4 extends to the bottom middle position 9 of the elevator door chute 10, and makes its top surface touch the bottom surface of the elevator door chute 10; on the other side of the sill body 1, The second side arm 3 bent longitudinally downward is formed by cold bending and rolling, and the lower end of the second side arm 3 is further bent inward and extended to form a second bottom bracket whose lower end sur...

Embodiment 2

[0029] This embodiment provides a figure 2 The manufacturing method of the elevator sill shown is basically the same as that in Embodiment 1, the difference is that in step (2), the other side of the sill body 1 is first folded back downwards to form the upper part 30 of the second side arm 3, Then, the inner end of the upper portion 30 is bent downwards and extends vertically downwards to form the lower portion 31 of the second side arm 3 . In this example, the upper portion 30 is horizontal, but the upper portion 30 may also be inclined. In this way, on the one hand, hard contact with the real object can be avoided; on the other hand, the bearing strength of the sill body is better enhanced.

Embodiment 3

[0031] This embodiment provides a image 3 The manufacturing method of the elevator sill shown, it comprises the following steps:

[0032] (1) Using stainless steel strip material, the elevator door chute 10 is formed by rolling in the middle, which is the sill body 1;

[0033] (2) By cold bending and rolling, one side of the sill body 1 is bent longitudinally downward to form the first side arm 2, and the lower end of the first side arm 2 is further bent inward and extended horizontally beyond the elevator door The side wall of the chute 10 forms the first bottom bracket 4, and the top surface of the first bottom bracket 4 will be in contact with the whole bottom surface of the elevator door chute 10, and the welding machine installed on the cold-formed steel machine is also used to synchronously The position where the first bottom bracket 4 contacts the elevator door chute 10 is welded. On the other side of the sill body 1, the sill body 1 is bent longitudinally down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com