Clamp for laser welding of double-metal band saw blade and welding device

A technology of laser welding and bimetallic strips, which is applied in the direction of laser welding equipment, metal sawing equipment, sawing machine tool manufacturing, etc., can solve the problems of bulky fuselage, harsh environmental requirements, and difficult placement, etc., and achieve manufacturing costs Low, guaranteed welding strength and weld size, easy installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

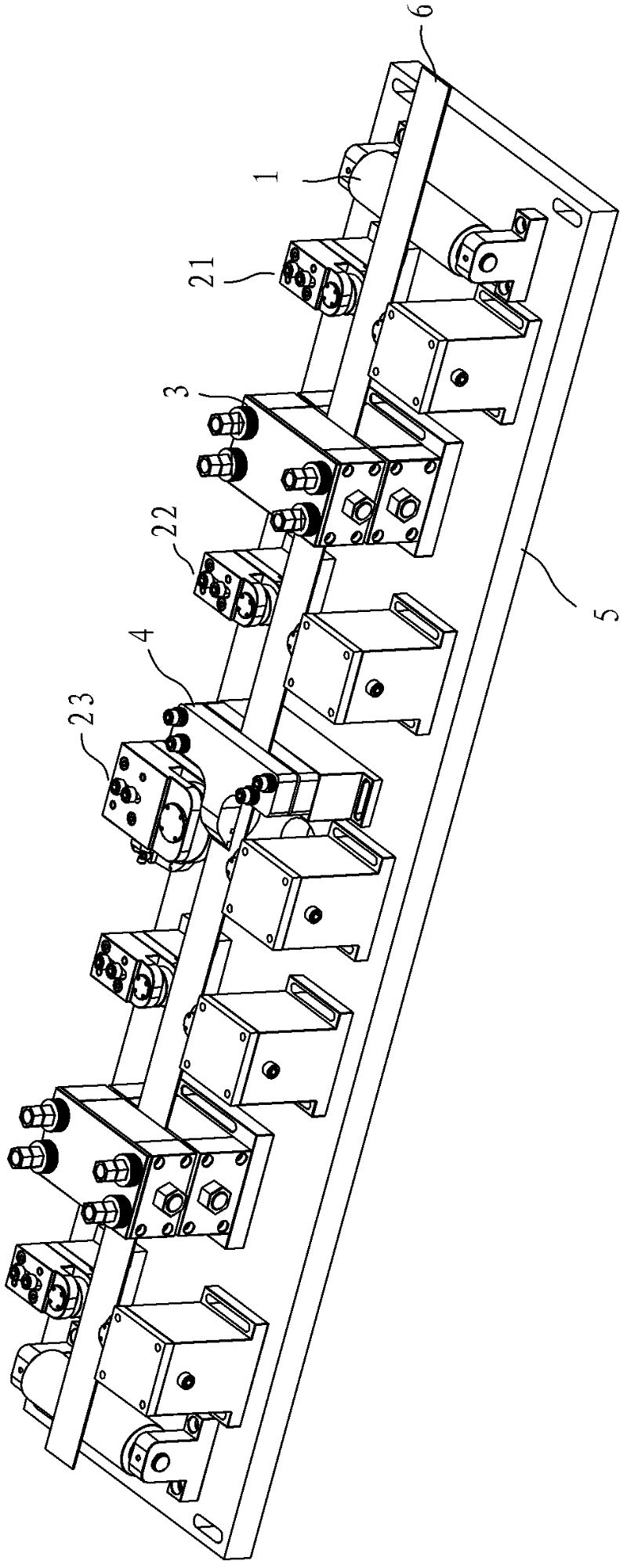

[0024] Such as figure 1 As shown, a jig for laser welding of a bimetallic band saw blade includes a bottom plate 5, and a guide roller 1, a positioning wheel set 21-23, a double pressure roller set 3 and a pressure roller set on the bottom plate 5 and on the same horizontal straight line. Tight mechanism4.

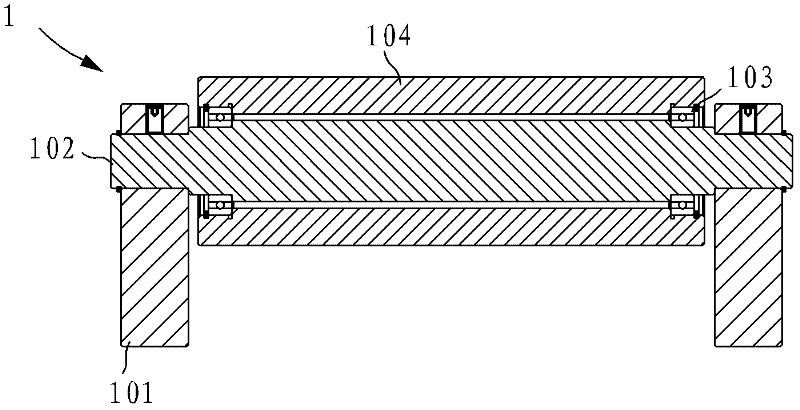

[0025] Such as figure 2 As shown, the guide roller 1 includes a roller sleeve 104 , a roller shaft 102 and a deep groove ball bearing 103 between them, and the guide roller 1 is installed on the bracket 101 .

[0026] Such as figure 1 As shown, the positioning wheel set includes two positioning wheels in the same plane and the wheel faces are vertically facing each other. The positioning wheels are installed on the fixed seat, and the two positioning wheels are facing to adjust the distance between the saw teeth and the back of the saw. Eventually push the sawtooth and sawback close together.

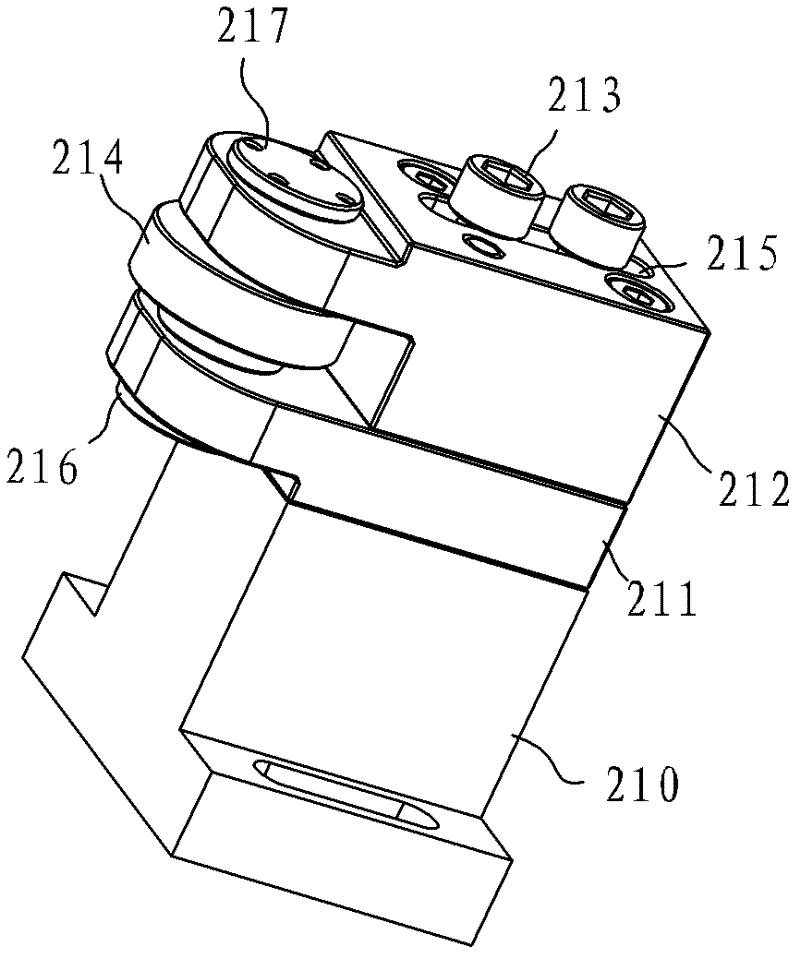

[0027] Such as image 3 and 4 As shown, the fixed seat includes a base 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com