Hot forming tool of titanium alloy thin-wall part and machining method of hot forming tool

A technology of thin-walled parts and titanium alloys, which is applied in the field of thermal processing, can solve the problems of poor forming quality of thin-plate parts, low heat utilization rate, waste of energy, etc., achieve the effect of constant temperature, uniform temperature distribution, and improved heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

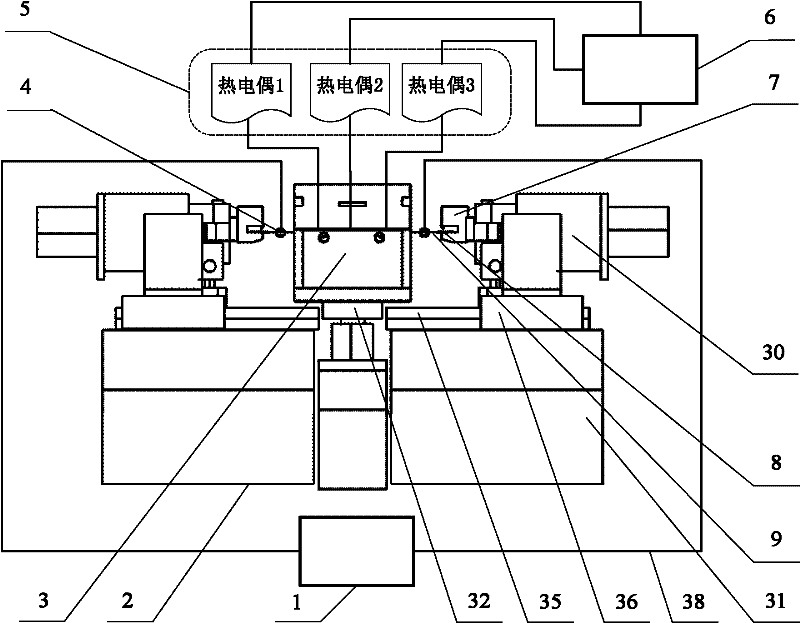

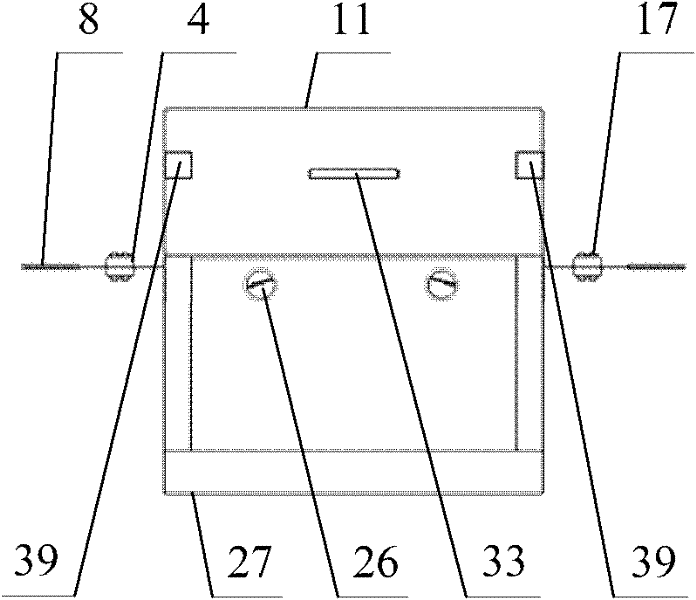

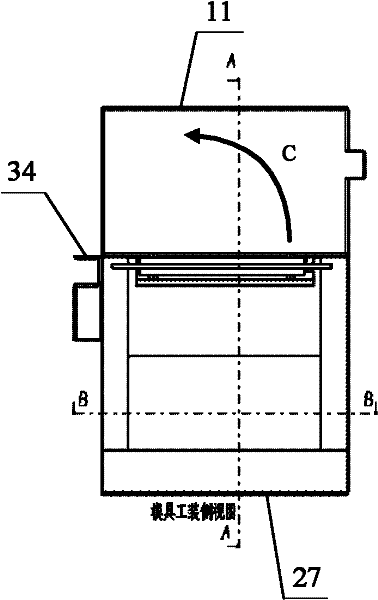

[0048] Attached below Figure 1 to Figure 7 , to further illustrate the technical solution of the present invention.

[0049] (1) A kind of thermoforming tooling of titanium alloy thin-walled parts of the present invention, it is made up of stretching equipment 2, mold device 3, blank 9, power supply system 1 and temperature control system 6 five parts, the position connection relation between them To: place the mold device 3 on the central workbench 32 of the stretching device 2, pass the blank 9 through the side wall gap 13 of the mold device 3, and use the insulating and heat insulating cushion layer 8 to make the blank 9 and the clamp of the stretching device 2 7. Insulate the surface of the mold 10 and its tooling, turn on the power supply system 1, energize the electrode splint 4, generate current in the blank 9, heat the blank 9, rely on the temperature control system 6 to measure and control the temperature of the blank 9, and wait for the blank 9 to reach the target ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com