Stirrer

A stirrer, dispersive stirring technology, applied in the direction of mixer accessories, chemical instruments and methods, chemical/physical/physical chemical fixed reactors, etc., can solve the problems of uneven stirring of local materials, easy jamming of stirring paddles, etc., to achieve Uniform distribution of shear rate, good stirring effect and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

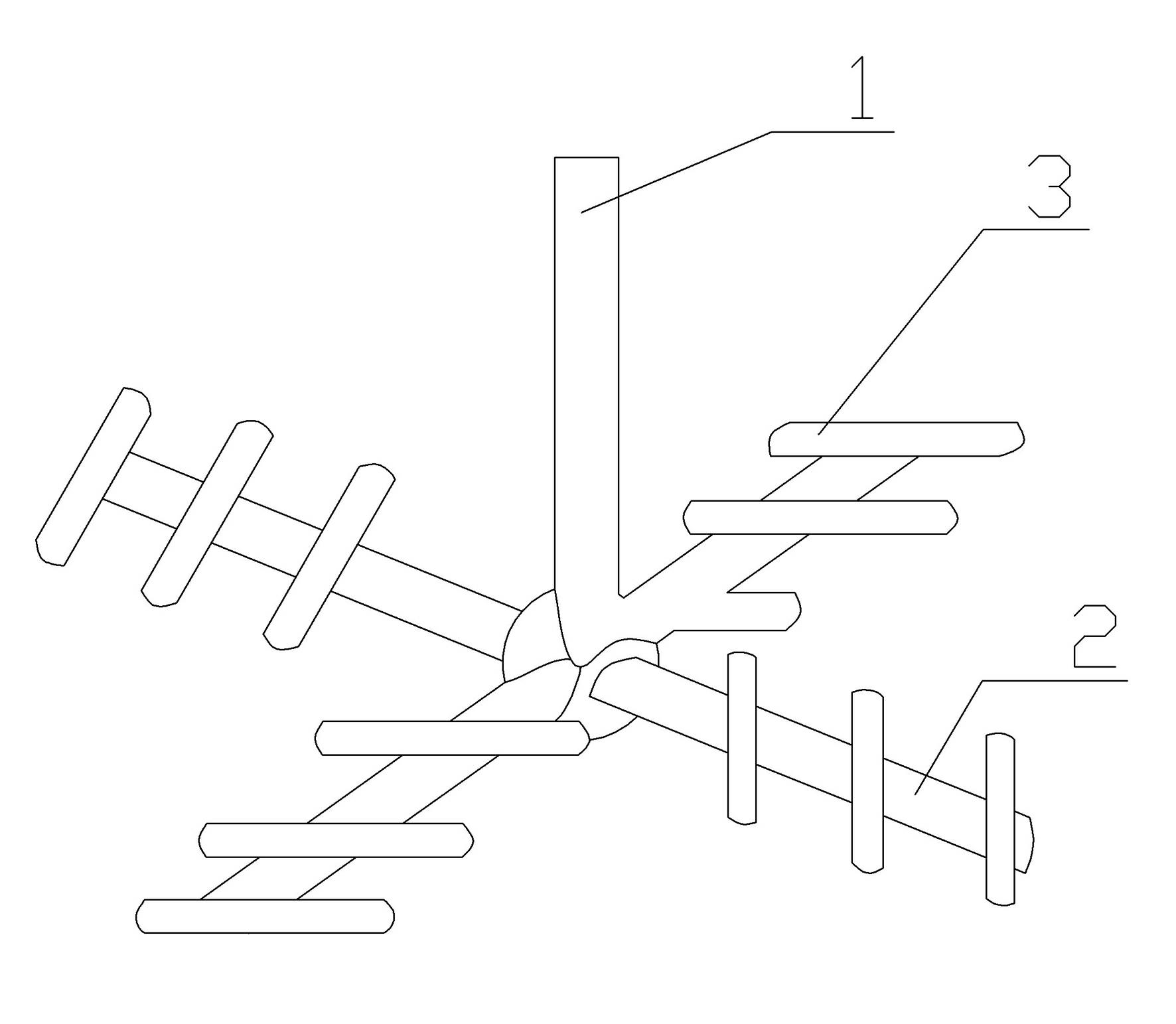

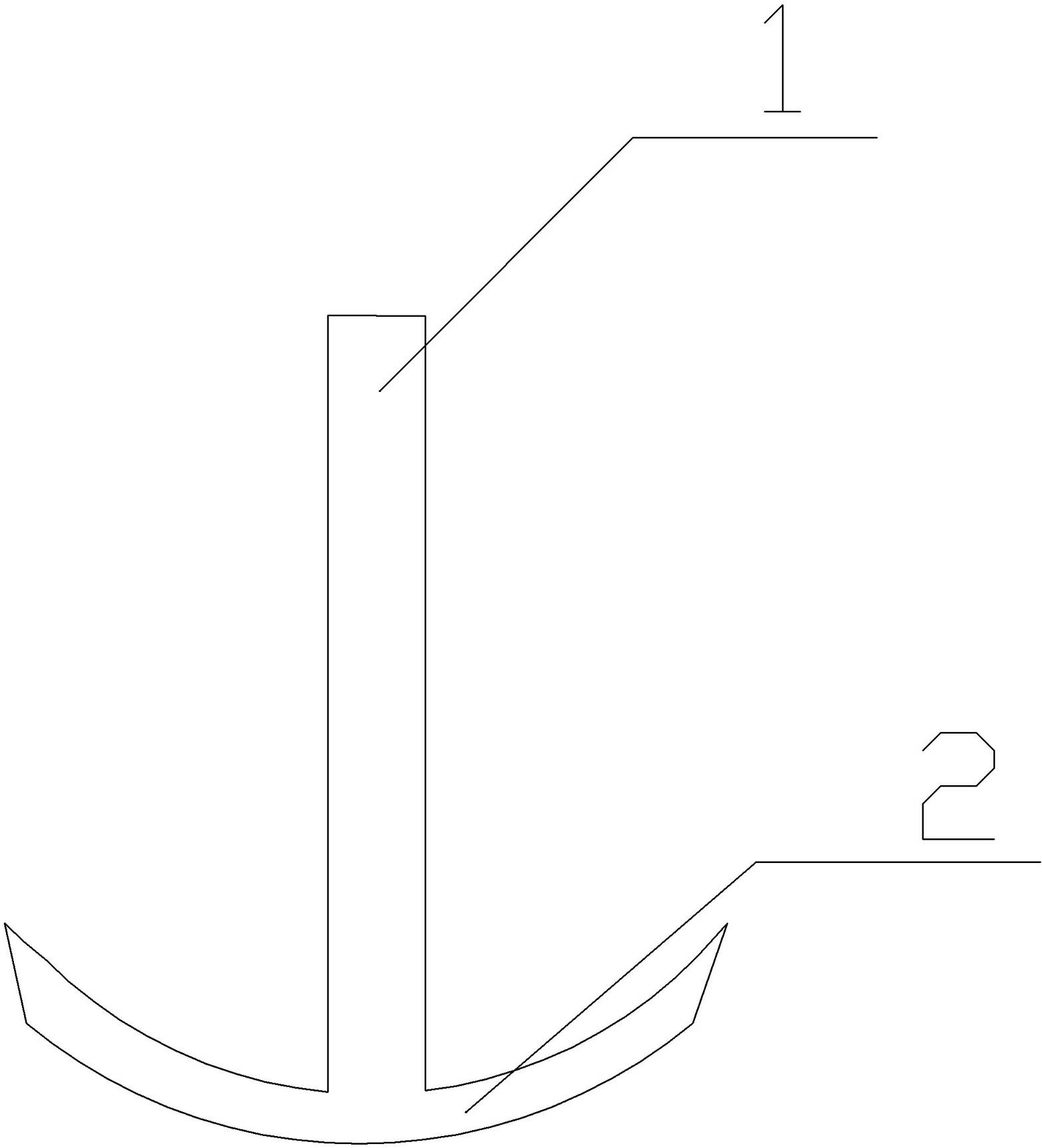

[0019] A kind of agitator, its stirring main paddle 1 has a first-level dispersion stirring branch 2, a second-level dispersion stirring branch 3 is arranged on the first-level dispersion stirring branch 2, and there are two first-level dispersion stirring branches 2 on the stirring main paddle 1, one The angle between the primary dispersing and stirring branch 2 and the secondary dispersing and stirring branch 3 is 90°, and there is a tertiary dispersing and stirring branch 4 above the secondary dispersing and stirring branch 3, which forms a certain angle with the secondary dispersing and stirring branch 3. Its shape is jagged.

Embodiment 2

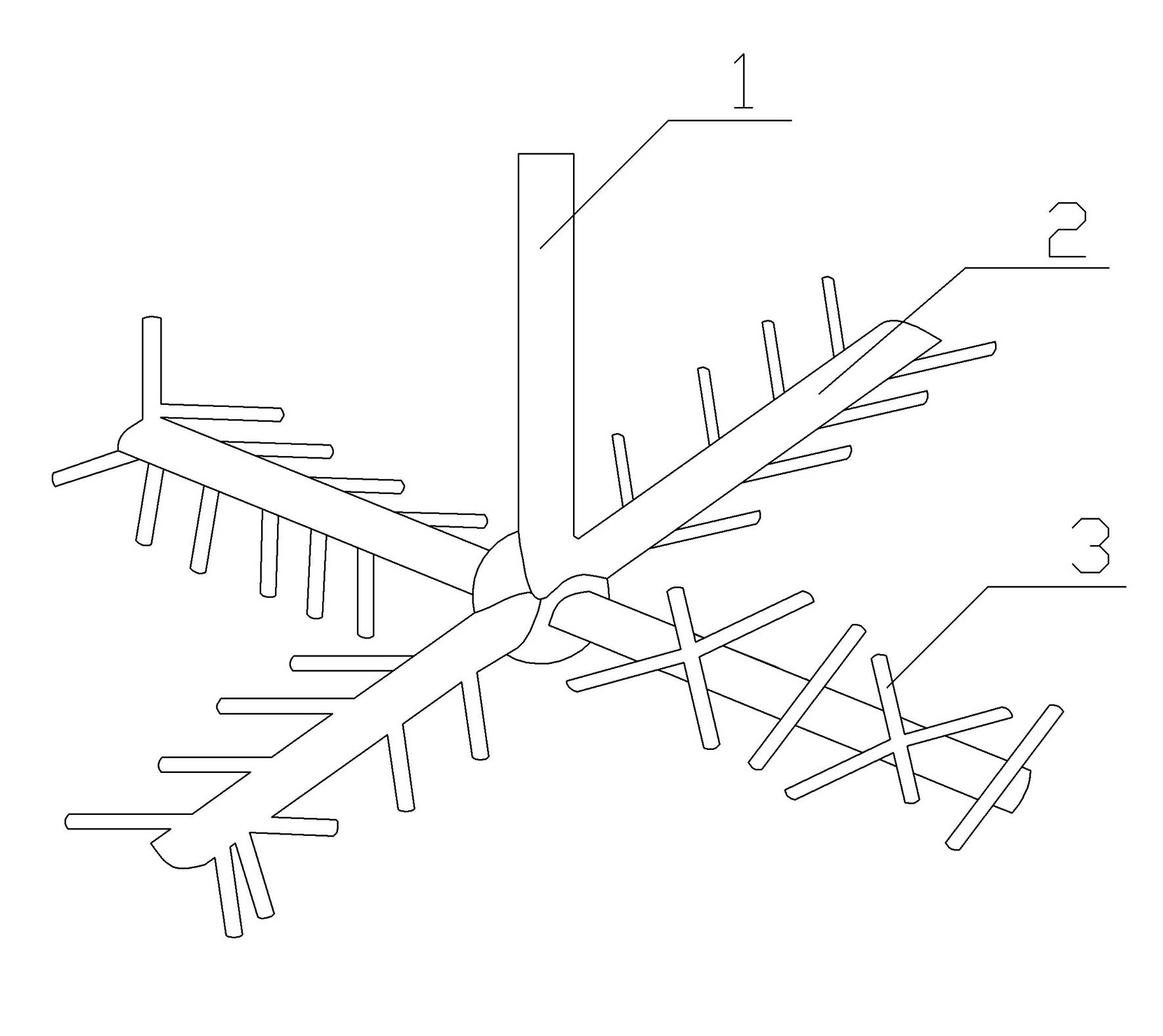

[0021] A kind of agitator, its stirring main paddle 1 has a first-level dispersion stirring branch 2, a second-level dispersion stirring branch 3 is arranged on the first-level dispersion stirring branch 2, and the number of first-level dispersion stirring branches 2 on the stirring main paddle 1 is four, two The angle between the stage dispersing and stirring branch 3 and the primary dispersing and stirring branch 2 is 30-150°, and its shape is tree-like.

[0022]

[0023] The present invention will be described in detail below in conjunction with specific test examples. The test examples are saw-toothed stirring paddles and tree-shaped stirring paddles, and the prior art is anchored stirring paddles, but not limited thereto.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com