Sectional magnetic yoke structure of synchronous alternating-current motor and processing method thereof

An AC motor, yoke structure technology, applied in the magnetic circuit shape/style/structure, magnetic circuit rotating parts, manufacturing stator/rotor body, etc., can solve the problem of processing, assembling trouble, prolonging the manufacturing cycle, and expensive forgings and other problems, to achieve the effect of simple assembly, reduced manufacturing cycle and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to further understand the features and technical content of the present invention, please refer to the following detailed description and drawings related to the present invention. However, the drawings are provided for reference and illustration only, and are not intended to limit the present invention.

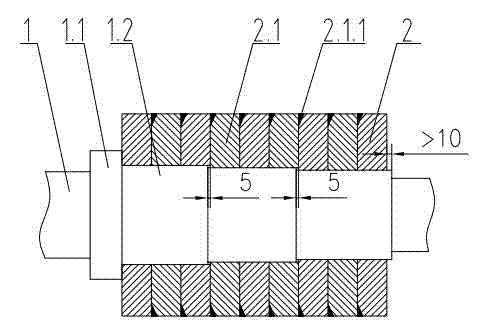

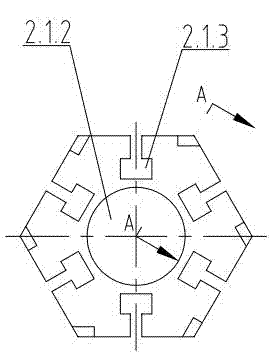

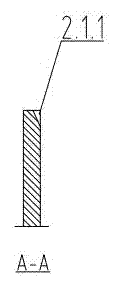

[0013] Such as figure 1 As shown, the segmented yoke structure of the synchronous AC motor of the present invention includes two parts of the shaft 1 and the yoke 2 . The shaft 1 includes the yoke matching section 1.2 and the shaft shoulder 1.1. The yoke matching section 1.2 is a segmented structure, and the diameter of each adjacent section differs by 2mm, decreasing from left to right, and its total length is at least longer than the yoke 2. Out of 10mm, the length of each yoke matching section 1.2 is about 300mm, and the specific length depends on the total length. The left side of the yoke fitting section 1.2 is a shaft shoulder 1.1, and the diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com