Machine for placing battery core into battery case for manufacturing lead-acid storage battery

A lead-acid battery, slot machine technology, applied in the direction of lead-acid battery, lead-acid battery construction, final product manufacturing, etc., can solve the problems of low efficiency, harmful to the health of operators, and pollution of the operating environment, so as to reduce the environmental impact. pollution, reduce instability, and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

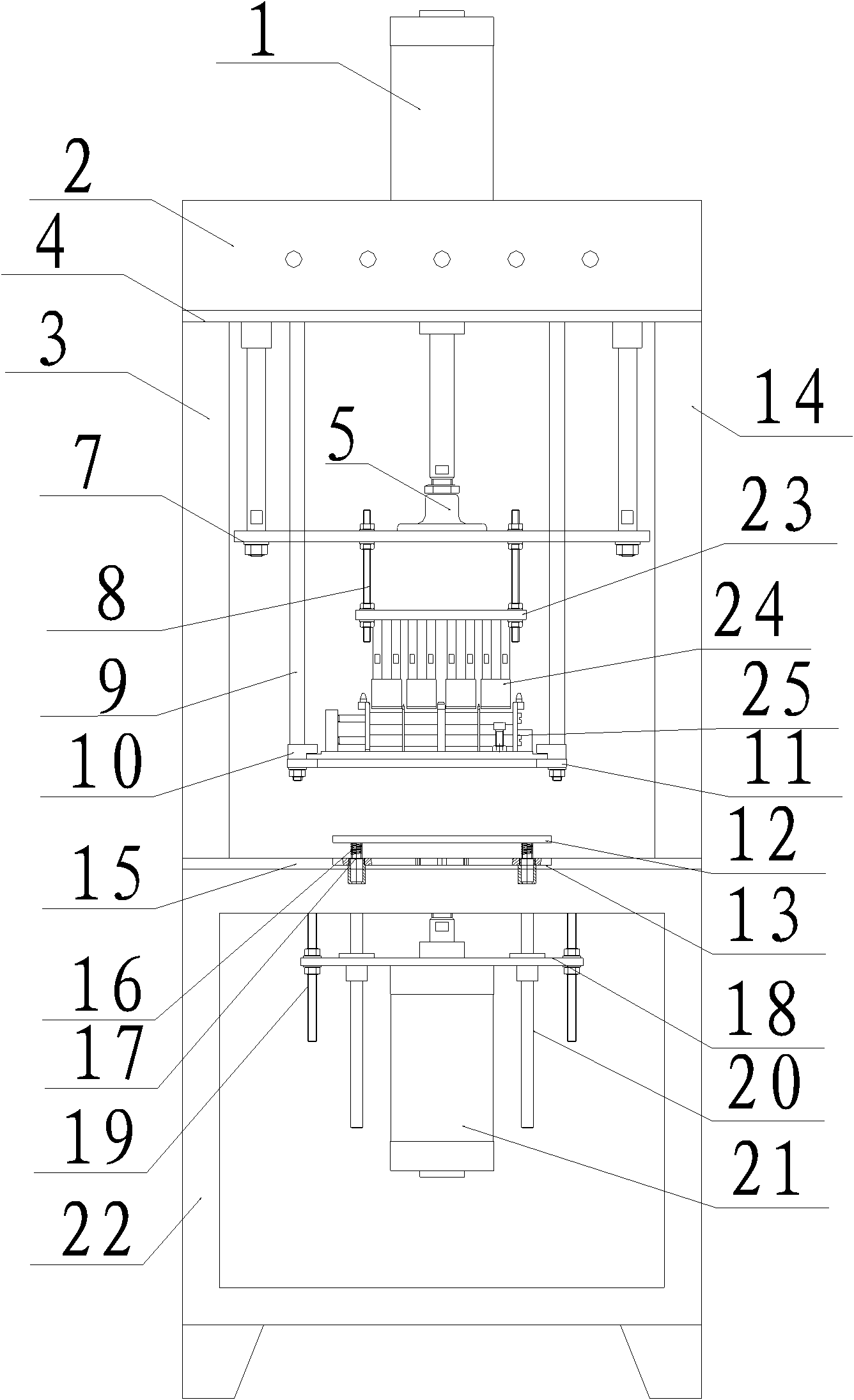

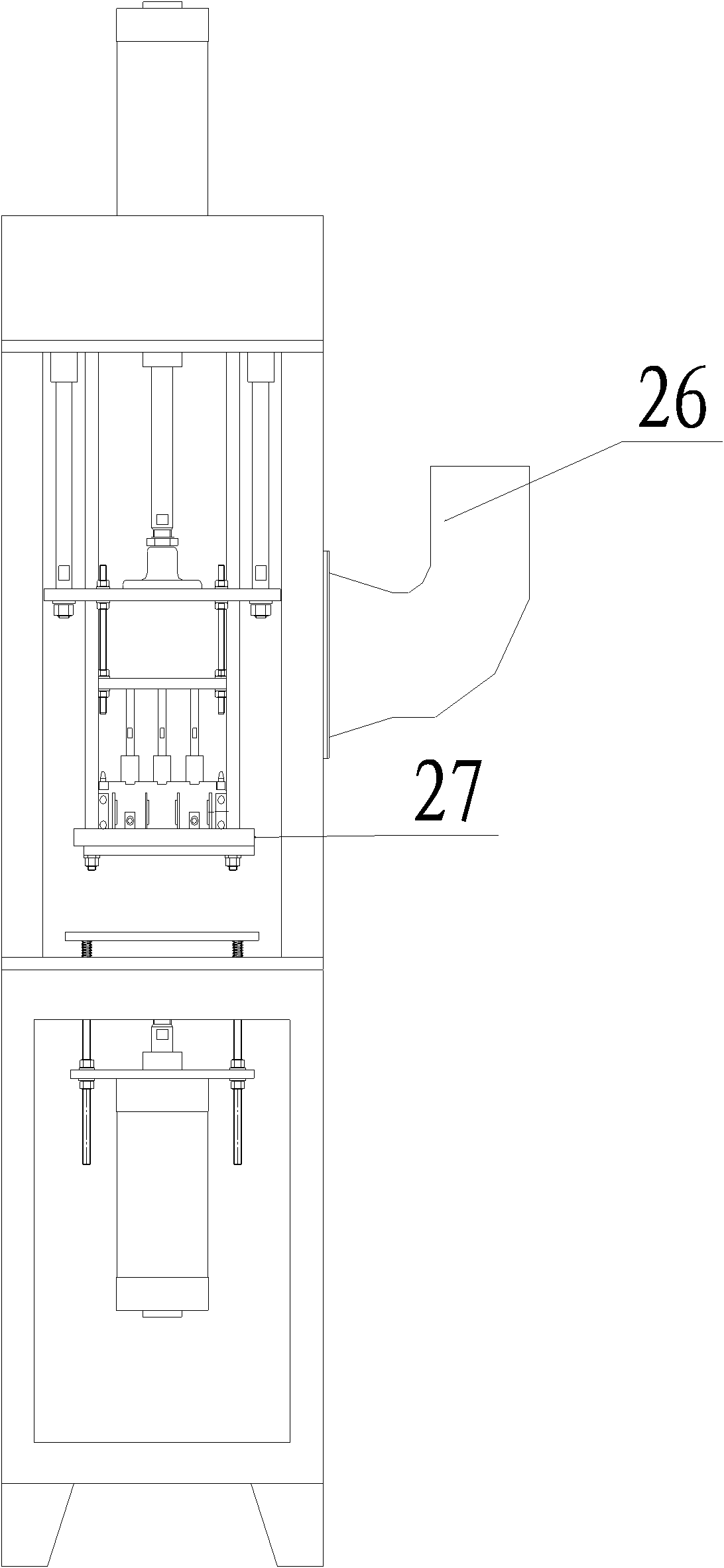

[0010] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments of the description:

[0011] Such as figure 1 , 2 As shown, it includes a box body, a cylinder, a battery case pallet, and a top column; the box body is divided into an upper box body 3 and a lower box body 22, and between the upper box body 3 and the lower box body 22 A lower panel 15 is provided; the cylinder is divided into an upper cylinder 1 and a lower cylinder 21, an upper cylinder 1 is provided above the upper box body 3, and a lower cylinder 21 is provided below the lower panel 15 , Between the upper cylinder 1 and the lower cylinder 22, there are sequentially provided a jack post 24 for pushing the battery core into the battery case, a mold clamp 25 for clamping the mold, and a battery case supporting plate for placing the battery case.

[0012] The cylinder body of the upper cylinder 1 is supported on the upper panel 4; the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com