Method for determining liquid medium refractive index by using optical fiber sensing technology

A kind of optical fiber sensing technology and liquid medium technology, applied in the direction of phase influence characteristic measurement, etc., can solve the problems of high price, difficult production, complicated operation process, etc., and achieve easy operation, low production and use cost, structure and measurement method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

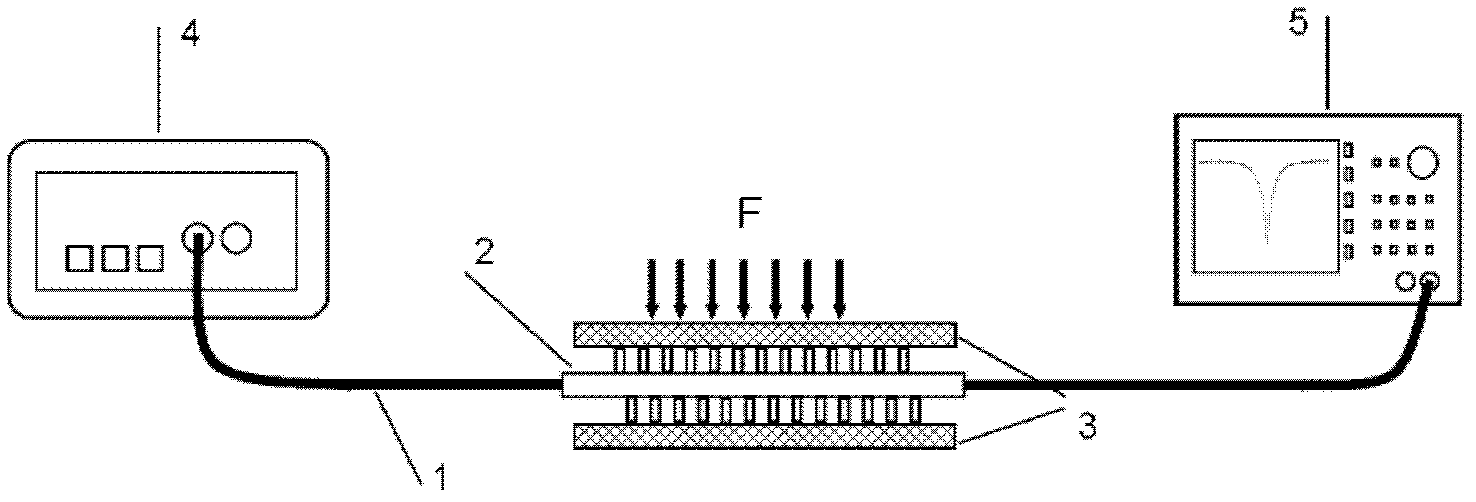

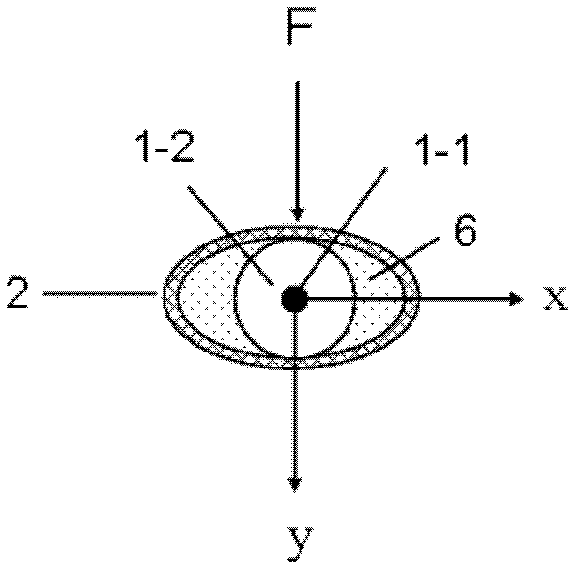

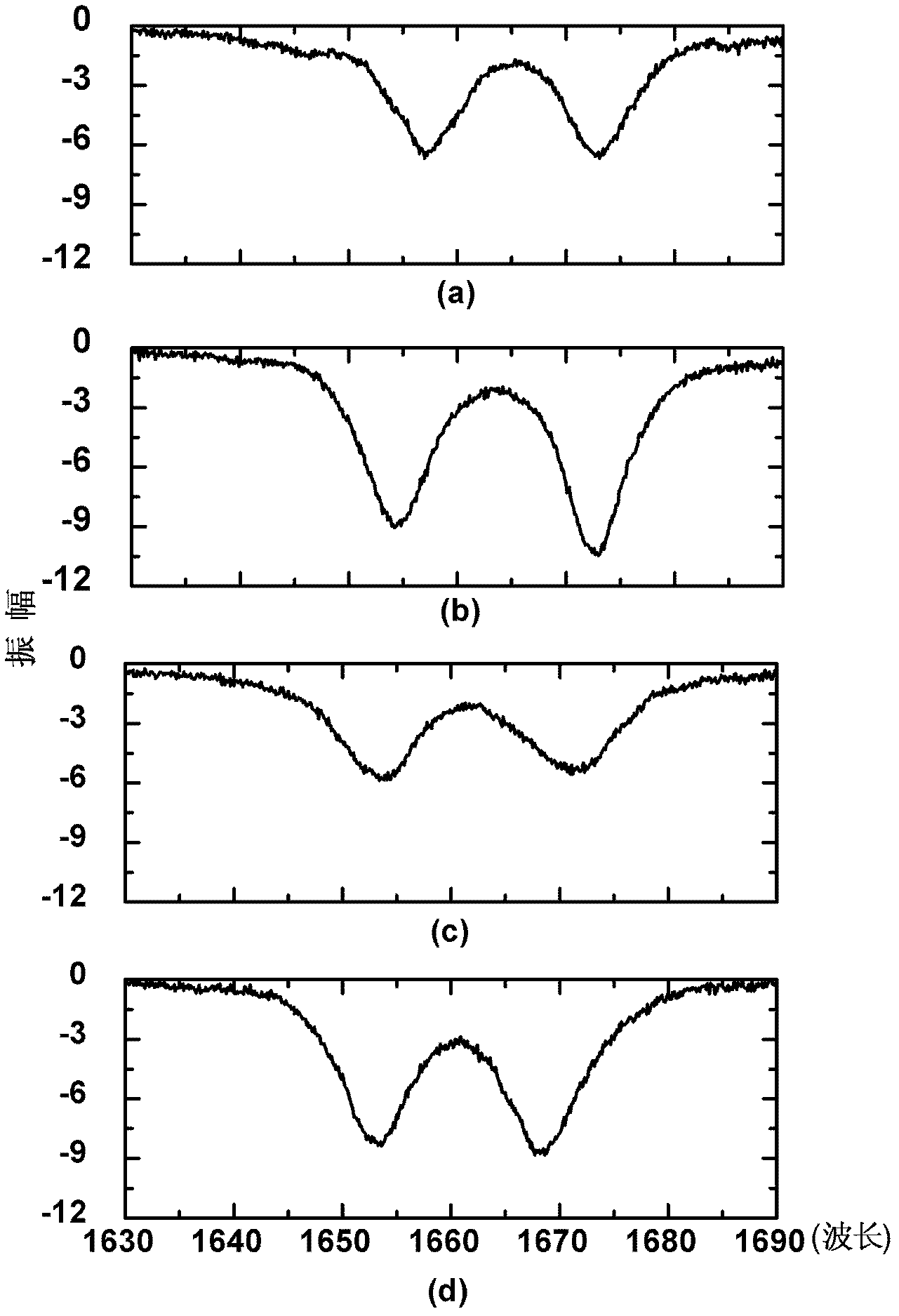

[0025] In this embodiment, the refractive index of NaCl solutions with different concentrations is measured as an example. Among them, the optical fiber 1 in the composite optical waveguide adopts SMF-28 single-mode optical fiber; the material of the sleeve 2 is polytetrafluoroethylene, and the wall thickness is 70 μm; 200 convex teeth with the same tooth spacing are set on the upper and lower rack plates 3, and the convex The tooth thickness is 200 μm, and the tooth spacing is 380 μm; the wide-spectrum light source 4 adopts Superk Compact, and the spectrum analyzer 6 model is AQ6370B; in this embodiment, NaCl and deionized water are used to configure the mass percent concentration of 0 (pure deionized water), 2wt %, 15wt% and 25wt% of the four liquid media as the solution to be tested 6, respectively injected between the casing and the cladding, and the composite optical waveguide injected into the solution to be tested is placed between the upper and lower rack plates 3 And ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com