Micro oil ignition staged combustion system

A staged combustion and micro-oil technology, applied in the field of thermal boilers, can solve the problems of poor mixing effect, poor ignition and stable combustion effects of pulverized coal flow, and achieve moderate investment and operating costs, high cost performance, enhanced ignition and stable combustion. burn effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

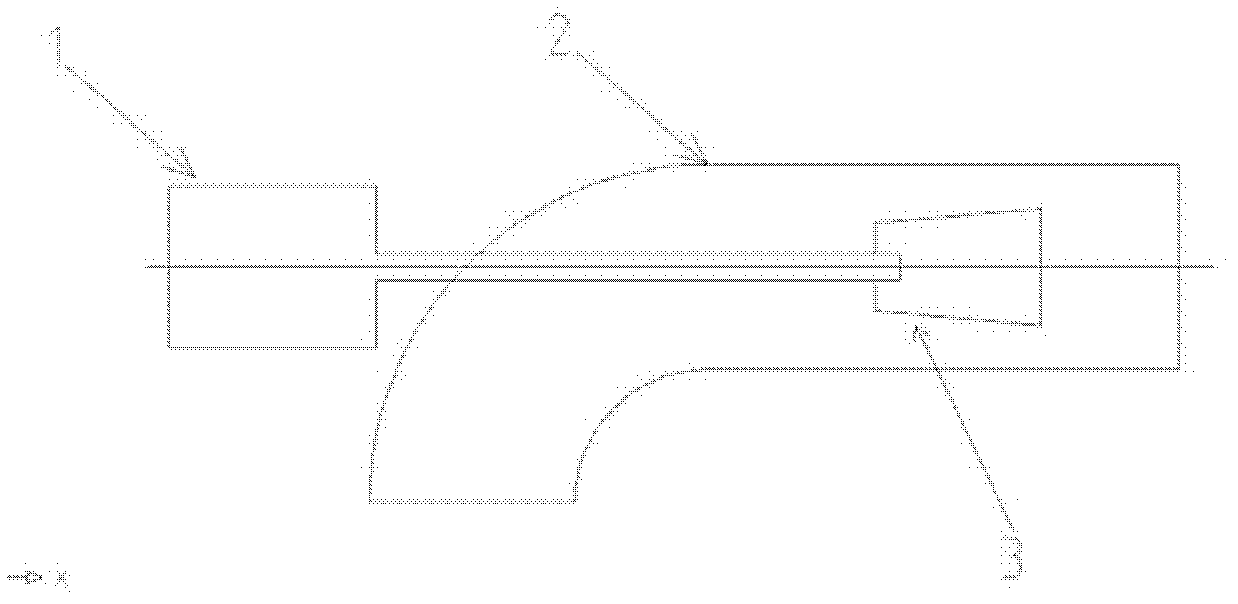

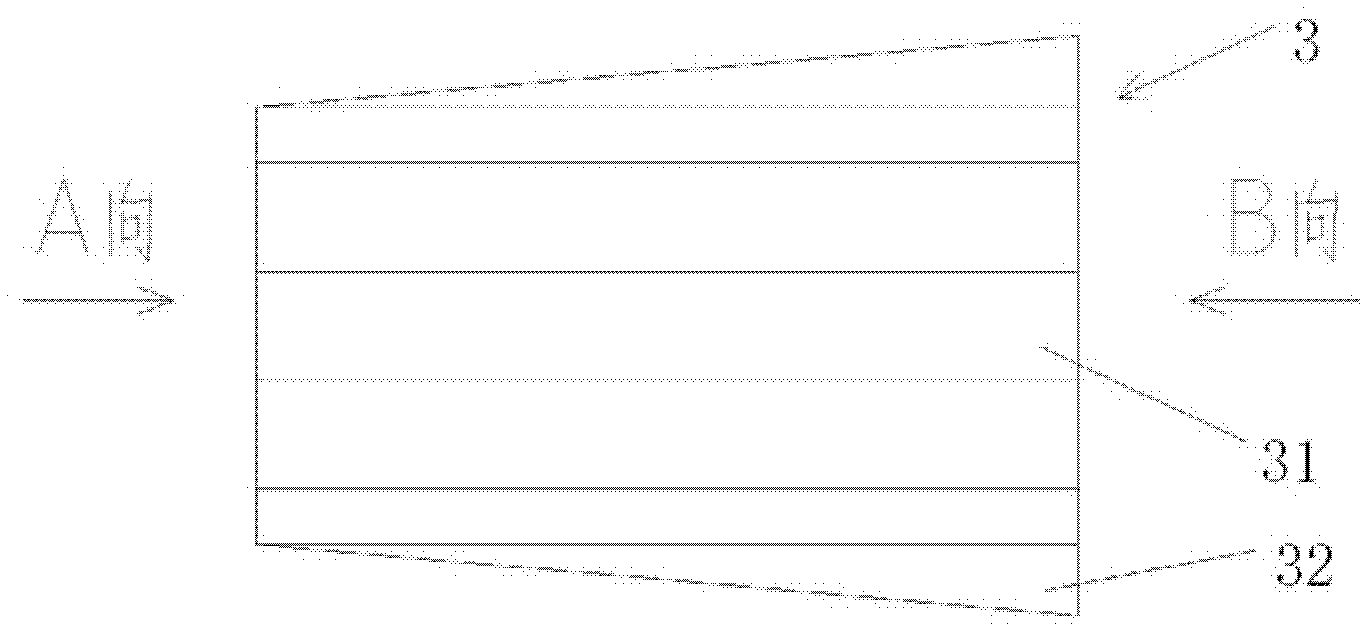

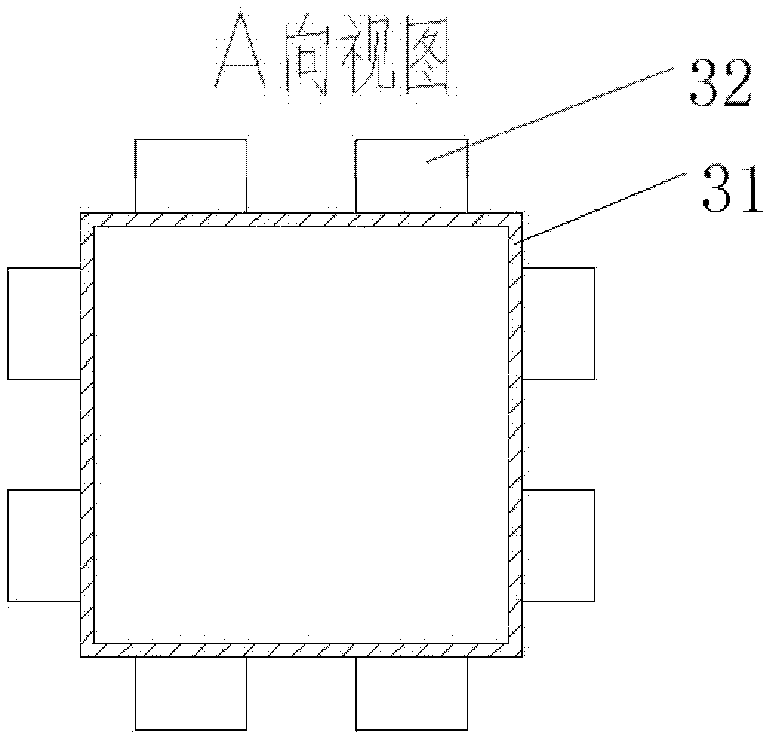

[0030] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , a kind of micro-fuel ignition staged combustion system of the present invention includes a micro-oil ignition device 1 and a burner 2. A staged combustion sleeve 3 is arranged inside the burner 2, and the staged combustion sleeve 3 and the burner 2 are arranged coaxially or in parallel. The graded combustion sleeve 3 has a sleeve main body 31. The cross-sectional shape of the sleeve main body 31 is square and equipped with a rectangular expansion cone 32. Two rectangular expansion cones 32 are arranged symmetrically on each side of the sleeve main body 31. The rectangular expansion cone 32 has a taper of 5°, the tip of the cone is at the entrance of the sleeve main body 31, the bottom of the cone is at the exit of the sleeve main body 31, and the sleeve main body 31 and the rectangular expanding cone 32 are integrated.

[0031] When the boiler is ignited, the micro-oil ignition device...

Embodiment 2

[0034] refer to figure 1 , Figure 7 , Figure 8 , Figure 9 and Figure 10 The difference between this embodiment and Embodiment 1 is that, in this embodiment, the sleeve main body 31 of the staged combustion sleeve 3 adopts a circular shape with a circular expansion cone 32. The four circular expansion cones 32 are evenly arranged on the On the side of the circumference, the cone tip of the expanding cone is at the entrance of the sleeve main body 31 , and the cone bottom of the expanding cone is at the exit of the sleeve main body 31 . The expanding cone 32 has a taper of 5°, and the sleeve main body 31 and the circular expanding cone 32 are integrated.

Embodiment 3

[0036] refer to figure 1 , Figure 11 , Figure 12 , Figure 13 and Figure 14 The difference between this embodiment and Embodiment 1 is that in this embodiment, the sleeve body 31 of the staged combustion sleeve 3 adopts a regular pentagon with a triangular expansion cone 32. Five triangle-shaped expansion cones 32 are evenly arranged On the side of the regular pentagon, the cone tip of the expanding cone is at the entrance of the sleeve main body 31 , and the cone bottom of the expanding cone is at the exit of the sleeve main body 31 . The expansion cone 32 has a taper of 5°, and the sleeve main body 31 and the triangle expansion cone 32 are integrated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com