Ground direct-driving screw pump oil extraction device for switched reluctance motor

A technology of switched reluctance motors and oil extraction devices, which is applied to pumps, mechanical equipment, machines/engines, etc. It can solve the problems that the anti-reverse device is easy to damage itself and the equipment, the speed of the screw pump is difficult, and the system efficiency is low. Reliable and intelligent control reverse electromagnetic brake function, overcome instability of parking brake, and good speed regulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

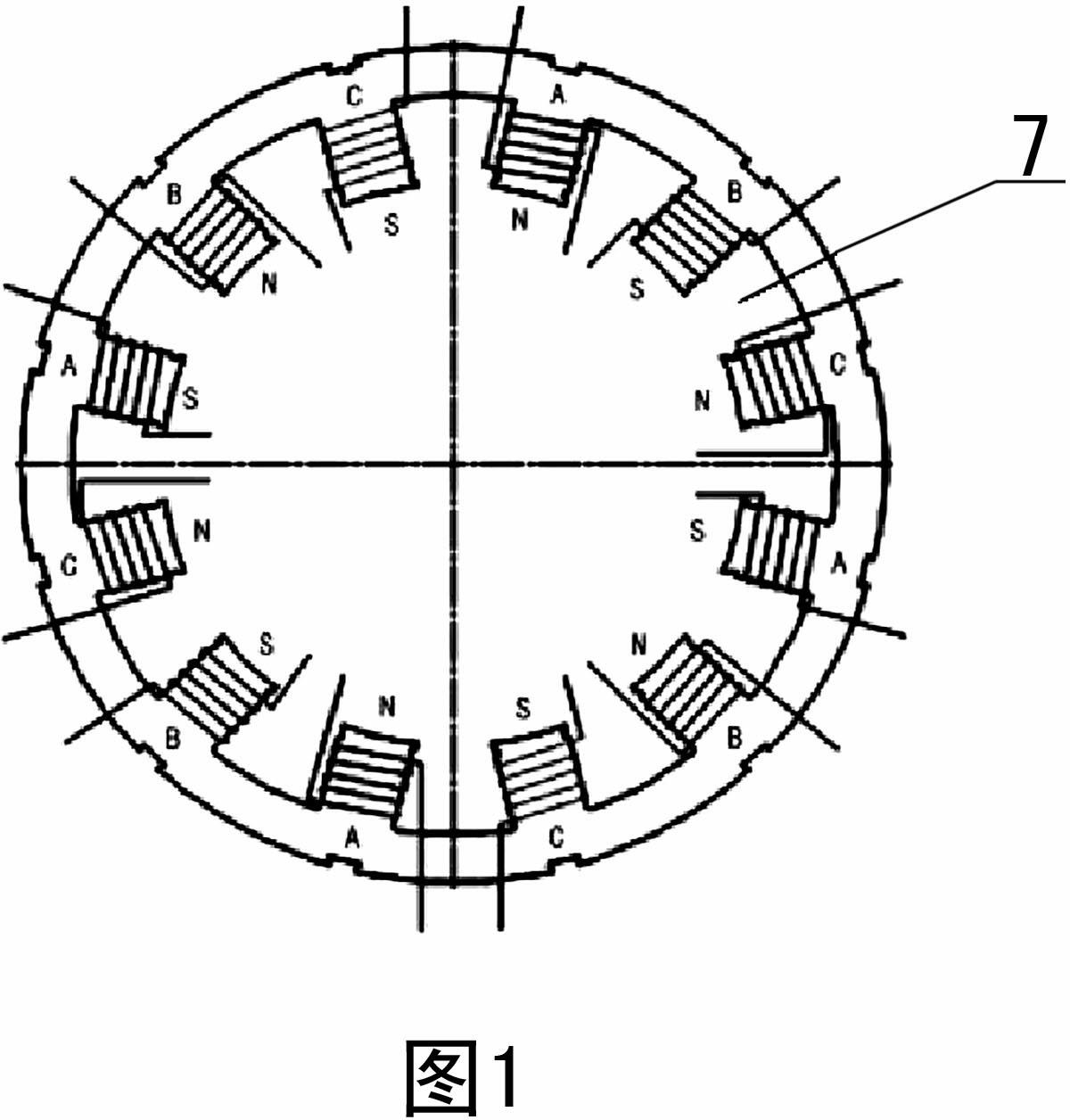

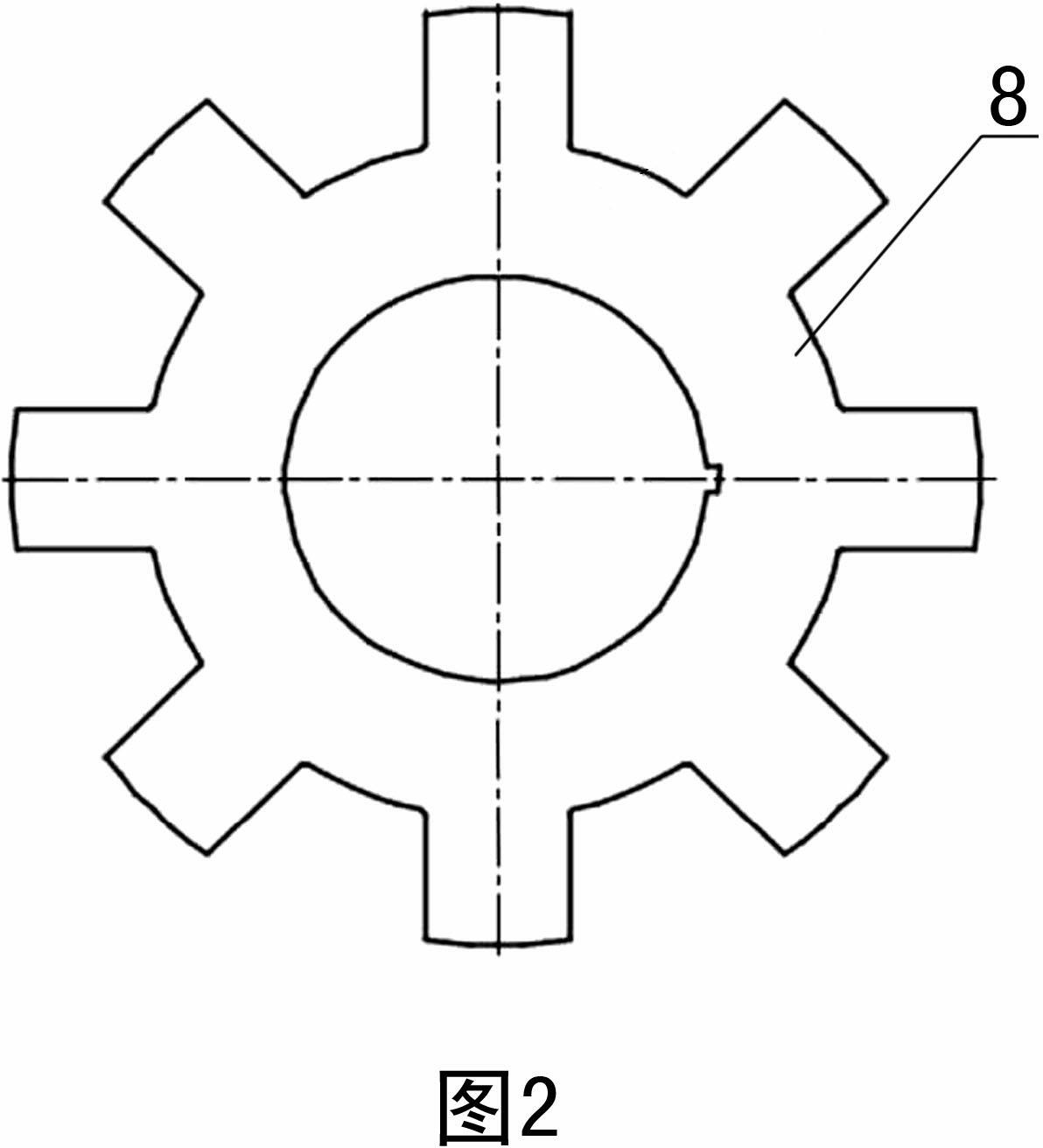

[0021] Embodiment 1: The switched reluctance motor 1 adopts a three-phase 12 / 8 structure, and the stator 7 is provided with three sets of stator teeth arranged radially opposite each other, and each stator tooth is provided with a concentrated winding coil, and the coil interval is divided into three phases , lead out from the cable, and the polarity distribution of each winding current is staggered when it flows in from the head end; the rotor 8 is provided with four groups of eight rotor teeth.

Embodiment 2

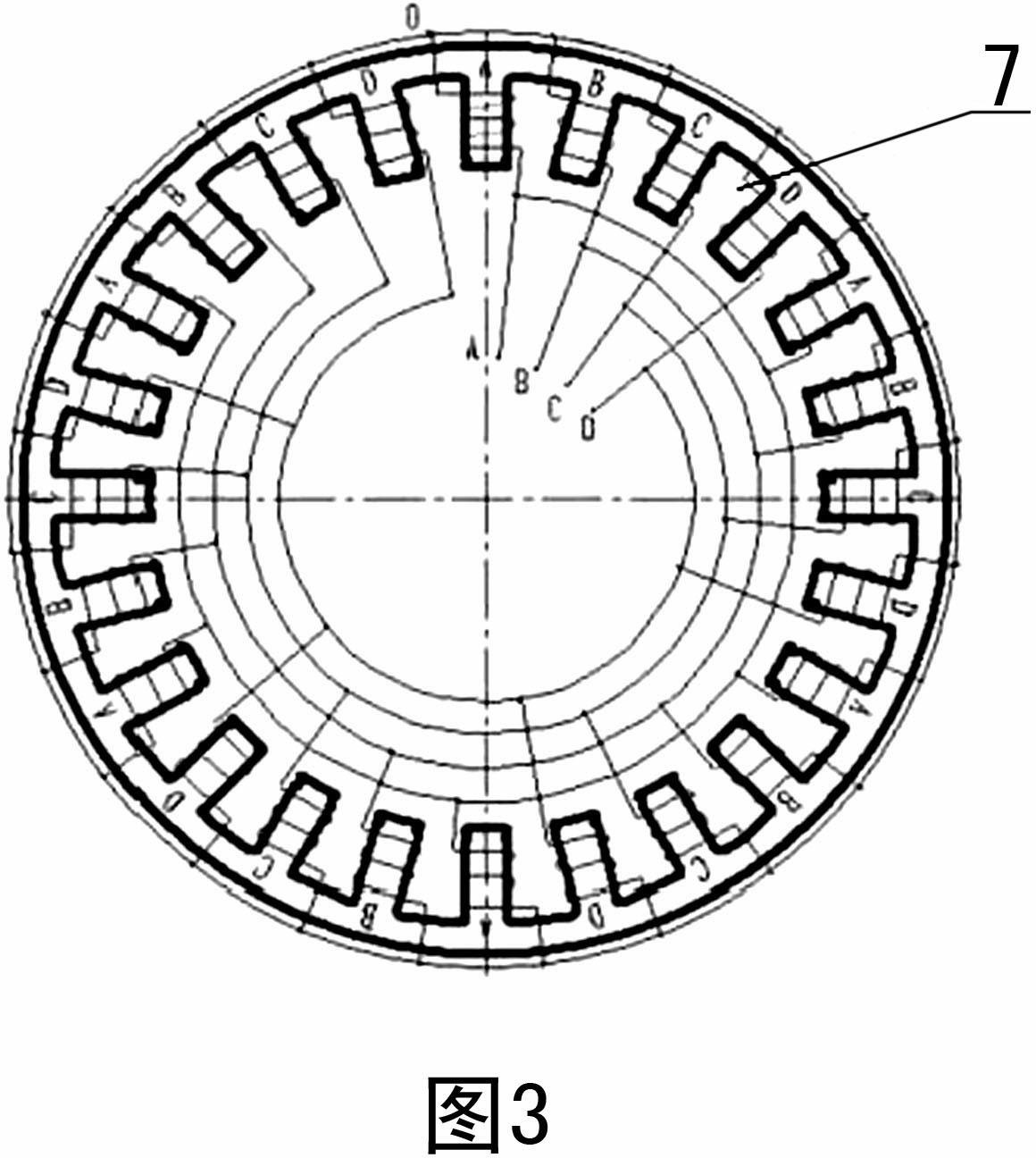

[0022] Embodiment 2: The switched reluctance motor 1 adopts a four-phase 24 / 18 structure, and the stator 7 is provided with four groups of radially opposite stator teeth, and each stator tooth is provided with a concentrated winding coil, and the coil interval is divided into four The phases are led out by cables, and the polarity distribution of each winding is staggered when the current flows in from the head end; the rotor 8 is provided with four groups of eighteen rotor teeth. The switched reluctance motor 1 of the present invention is designed for low-speed and high-torque occasions. The switched reluctance motor adopts two different structures depending on the power used and the size of the motor, which is convenient for users to use.

[0023] See attached Figure 5-6 As shown, the structural block diagram and connection schematic diagram of the switched reluctance motor drive system. This switched reluctance motor surface direct-drive screw pump oil production device i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com