Energy-saving door and window profile formed by adhering aluminum on solid wood and manufacture method thereof

A technology for door and window profiles and a manufacturing method, applied in the field of new materials for energy-saving doors and windows with solid wood aluminum film, can solve problems such as low thermal conductivity, achieve the effects of simple and warm texture, prevent warping, and save resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

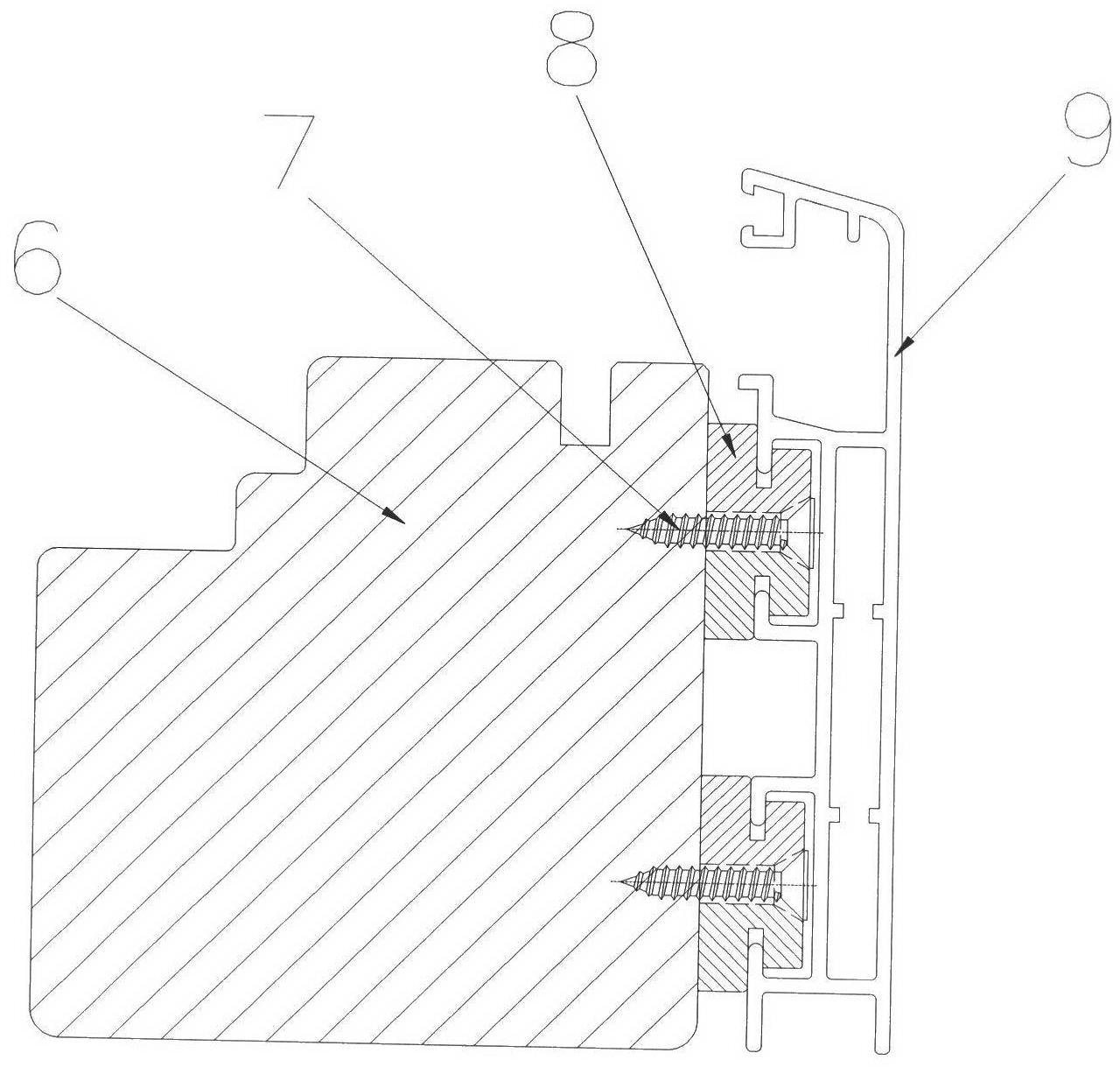

[0052] pass below Figure 5 A kind of specific embodiment of the utility model is introduced.

[0053] Such as Figure 5 As shown, a solid wood aluminum-clad energy-saving door and window profile of the present invention includes solid wood finger-jointed glulam 10, PUR reactive polyurethane hot melt adhesive 11 and aluminum alloy coil 12; the aluminum alloy coil 12 is passed through PUR reactive polyurethane The hot melt adhesive 11 is pasted on the surface of the solid wood finger-jointed lumber 10 . The thickness of the PUR reactive polyurethane hot melt adhesive 11 is 0.12-0.20mm. The surface of the solid wood finger-jointed glulam 10 is coated with paint, and the thickness of the paint film is 120 μm-170 μm.

[0054] A method for manufacturing solid wood aluminum-clad energy-saving door and window profiles of the present invention comprises the following steps:

[0055] (1) Drying and splicing the wood into square wood glulam;

[0056] (2) Plane the square wood glula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com