Cast-in-place concrete core column ring beam house manufactured by light composite board and assembling method

A light-weight composite panel and house technology, which is applied in the direction of flat/curved panel roof, roof, roof cladding, etc., can solve the problem of poor durability and sound insulation, easy rainwater leakage at the junction of panels, earthquake resistance and wind resistance Poor capacity and other problems, achieve superior negative wind pressure resistance, solve thermal insulation problems, and install quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, the house and the assembly method using the lightweight composite board cast-in-place concrete core column ring beam of the present invention will be described in detail in conjunction with the accompanying drawings.

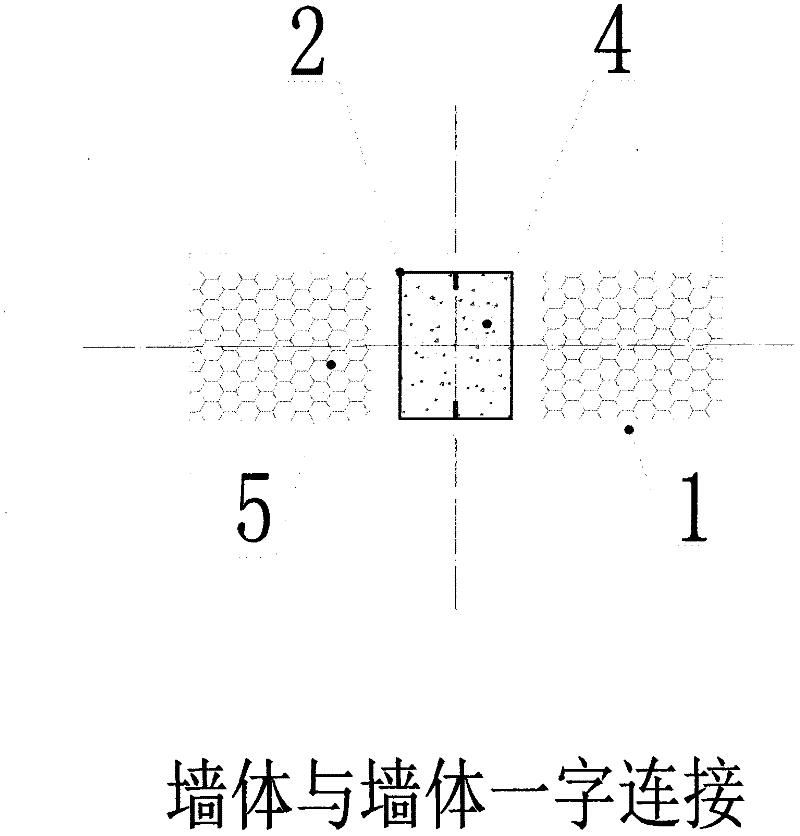

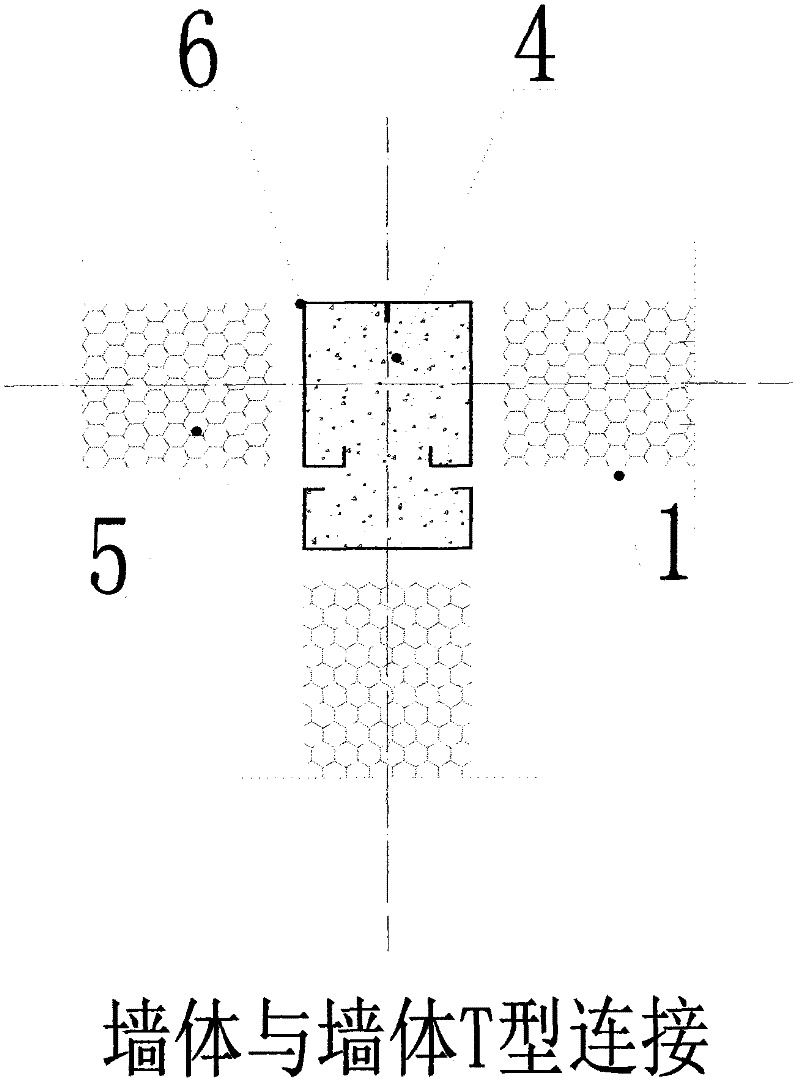

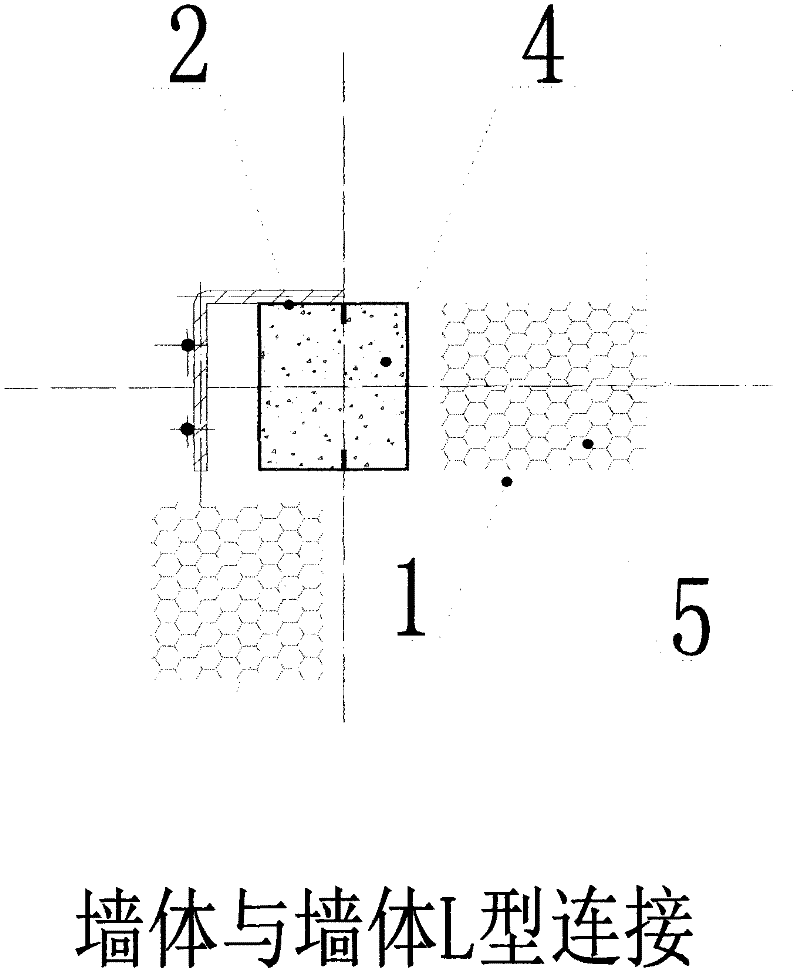

[0028] combine first figure 1 Introduces the assembly method of the house using the lightweight composite slab cast-in-place concrete core column ring beam. The two lightweight composite panels are connected in a straight line, and the C-shaped steel 2 on the opposite side of the two lightweight composite panels forms a closed space. The joints between the plates are leveled with polymer mortar caulking, and when the strength reaches a certain level, the material used to form the core column 4 is poured into the space to form the concrete filled steel pipe of the wall. Thus, two lightweight composite boards are used to form a wall; when the assembled wall is an exterior wall, polymer fine stone concrete or thermal insulation material is pour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com