Structure capable of realizing large-span V-shaped pier continuous rigid frame bridge and construction process thereof

A construction technology and large-span technology, applied in the field of transportation, can solve the problems of reduced driving comfort, structural integrity, and unfavorable shock resistance, and achieve the effects of reduced consumption, simple structure and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

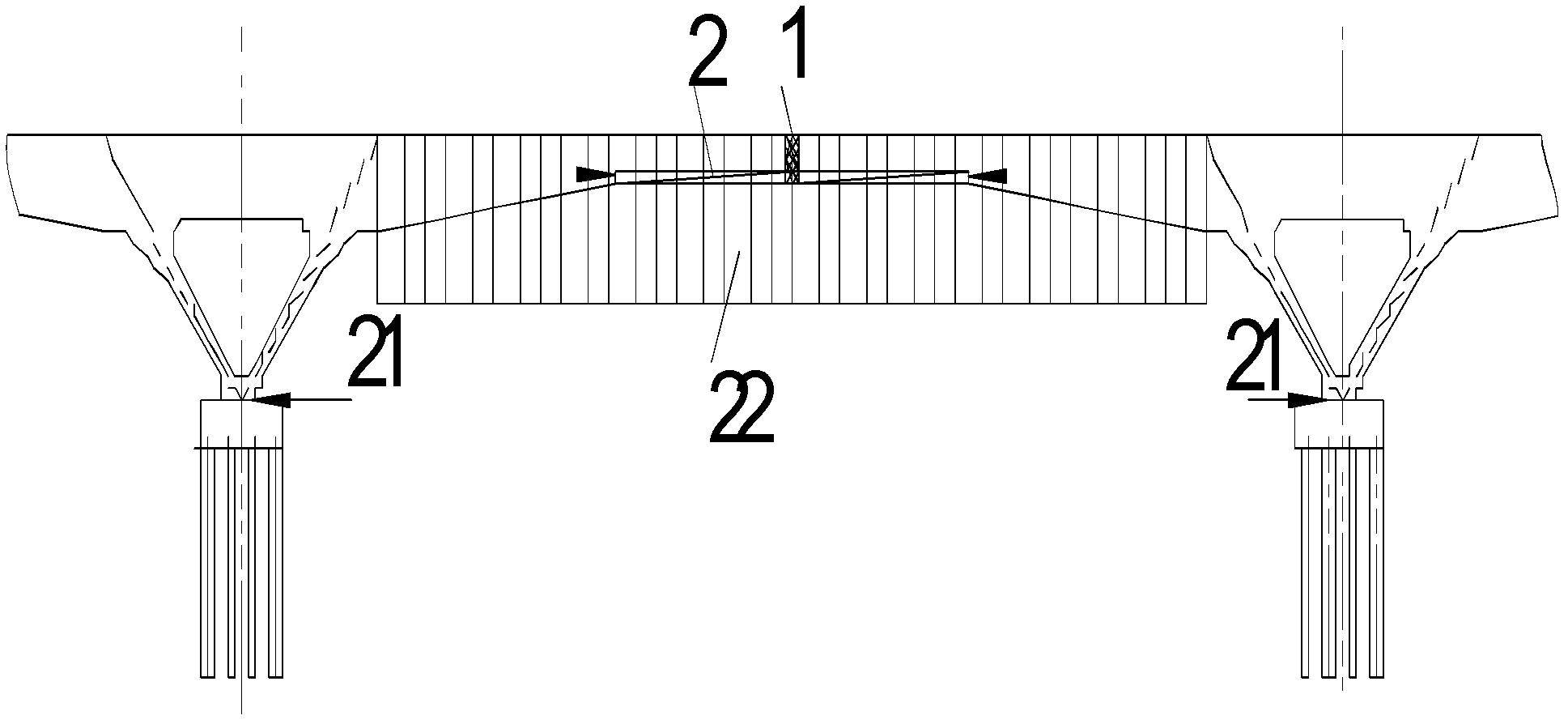

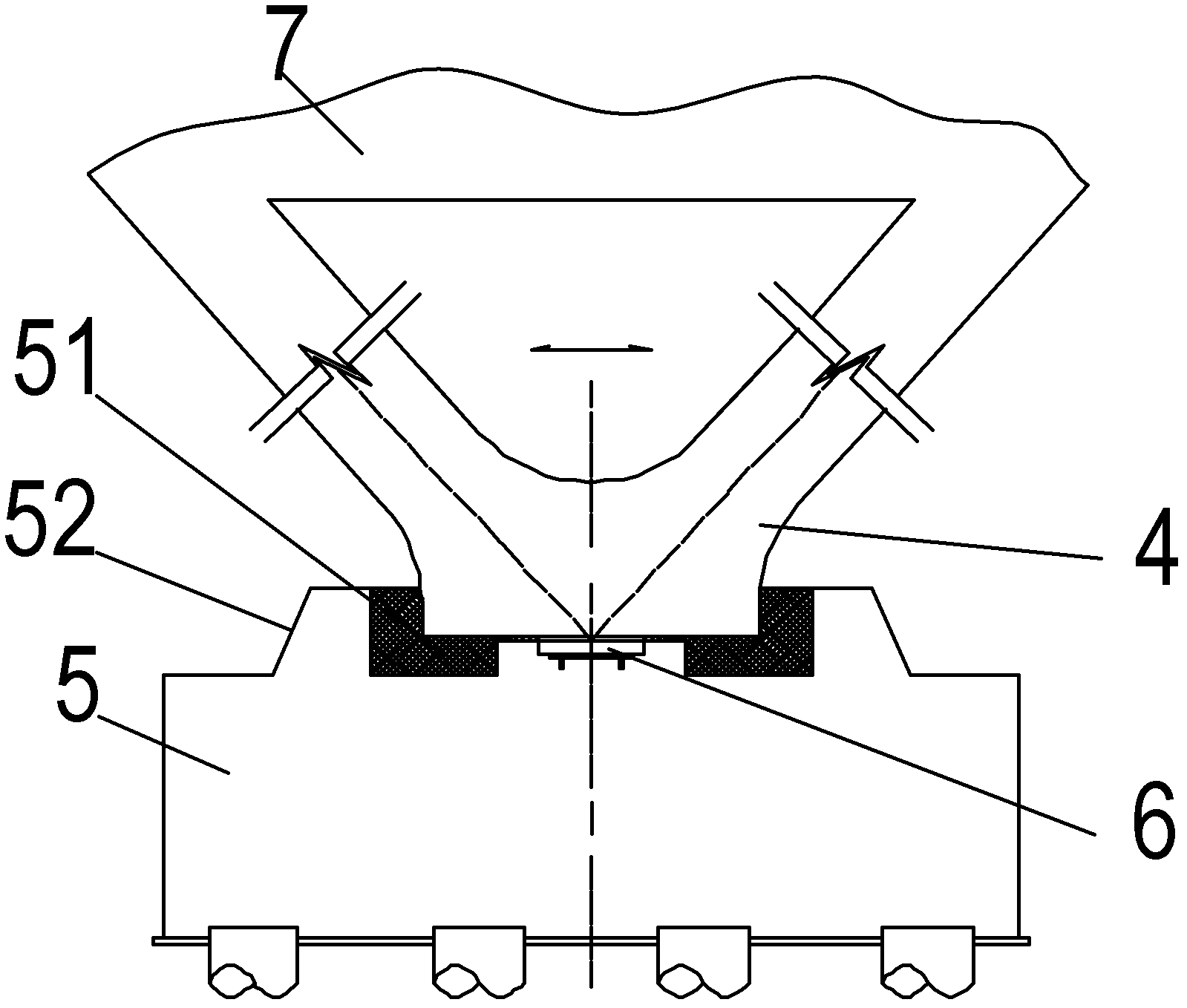

[0032] Such as figure 2 , image 3 As shown, the present invention provides a structure of a continuous rigid-frame bridge with large-span V-shaped piers, which mainly includes a beam body and a V-shaped pier bottom connection structure.

[0033] The special feature of the present invention is that the V-shaped pier bottom connection structure can adjust the support state according to the construction conditions: temporary limit fixation, temporary longitudinal sliding or permanent consolidation.

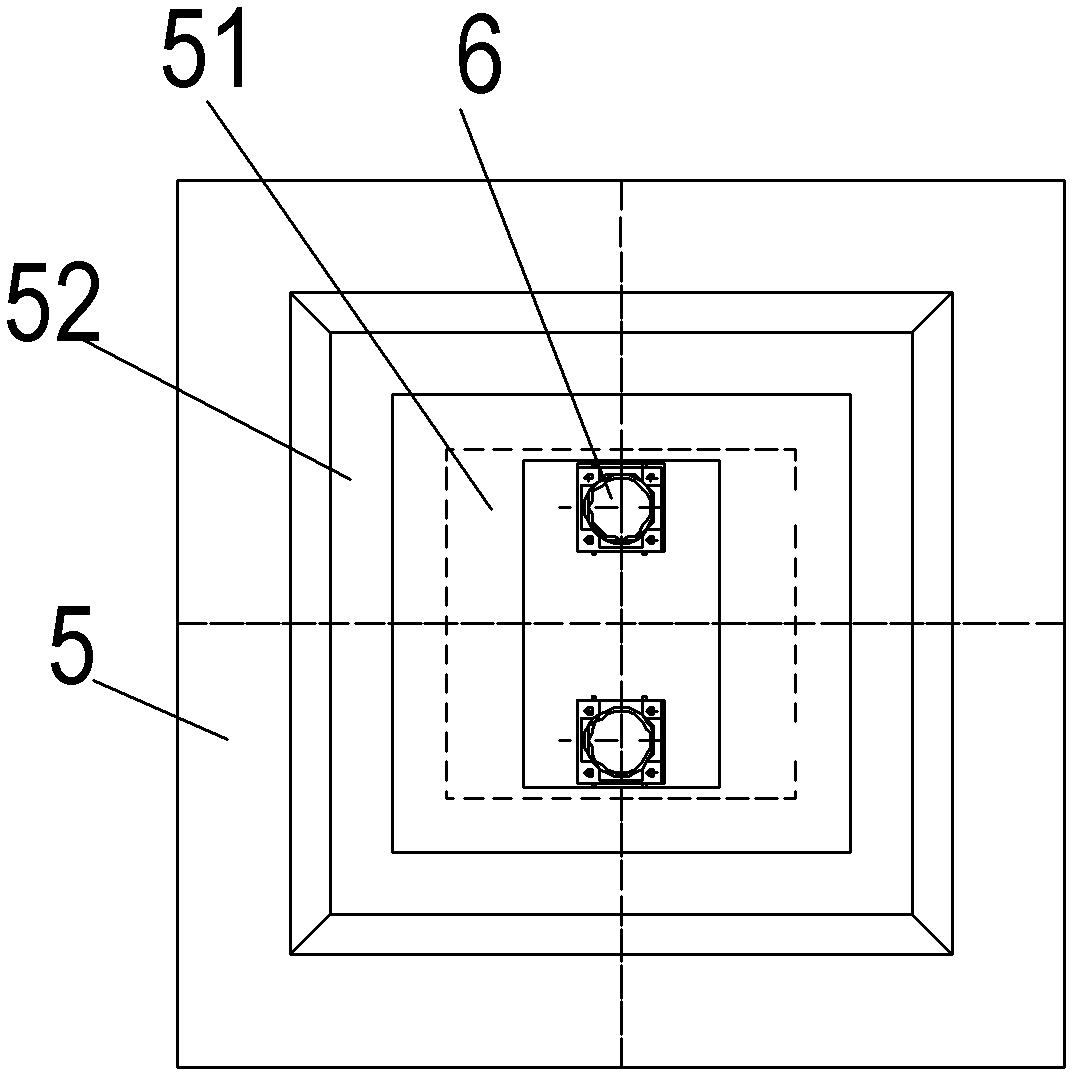

[0034] Specifically, the V-shaped pier bottom connection structure includes a V-shaped pier component 4 and a pier bottom bearing platform 5 , and also includes a temporary longitudinal sliding support 6 . The V-shaped pier part 4 and the zero block 7 of the beam body form a triangular section, and the pier bottom cap 5 is generally a pile group foundation. The temporary longitudinal sliding support 6 is the main component to realize the sliding of the bottom of the pier in the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com