Internal lubricant for polyvinyl chloride (PVC) resin molding processing and preparation method thereof

A technology of PVC resin molding and processing, applied in the direction of organic chemistry, etc., can solve problems such as lack of auxiliary thermal stability of internal lubricants, single product performance, and inability to adapt to the requirements of PVC resin molding processing, etc., to reduce production costs, compatible Good performance and performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Prepare the internal lubricant for PVC resin molding processing of the present invention according to the following steps:

[0056] ①. Feeding and heating

[0057] Put 78.9 parts by weight of epoxy oleic acid, 20.9 parts by weight of methyl diethylene glycol, and 00.2 parts by weight of butyl titanate into the reaction kettle, and heat up to 100°C under stirring;

[0058] ②.Condensation reaction

[0059] Step ① Feeding the heated material, under the pressure of -0.09Mpa, continue to stir, slowly raise the temperature to 190°C, and keep it warm at 190°C for 5 hours to obtain a light yellow or transparent fluid liquid. Under normal pressure, cool down to a constant temperature of 100°C, and prepare slices;

[0060] ③. Slicing and packaging

[0061] Step ② The condensation reaction product is sliced by a drum-type condensation crystal slicer, and packaged after passing the quality inspection.

Embodiment 2~ Embodiment 8

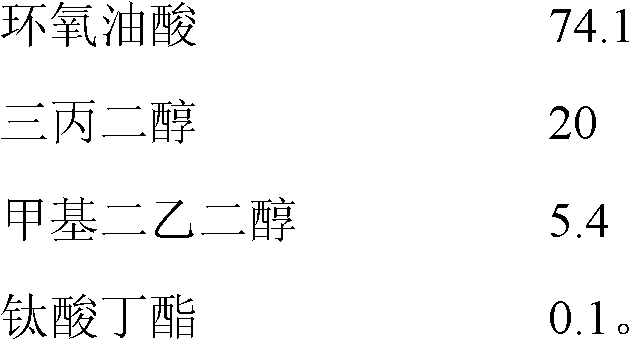

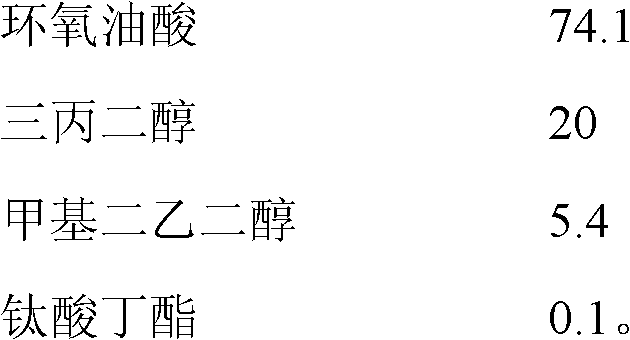

[0063] According to the method and steps of Example 1, according to the formula of Table 1, the internal lubricant for PVC resin molding processing of the present invention is prepared

[0064] Table 1

[0065] raw material

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com