Production method of high-purity PPS-OH

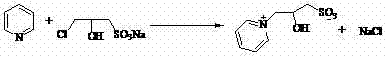

A technology of pure hydroxypropane sulfonate pyridinium salt and hydroxypropane sulfonate pyridinium salt, which is applied in the production field of high-purity hydroxypropane sulfonate pyridinium salt, can solve the problem of unfavorable transportation and increase of hydroxypropane sulfonate pyridinium salt solution Difficulty in handling Plating parts are brittle and affect the brightness of the nickel layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

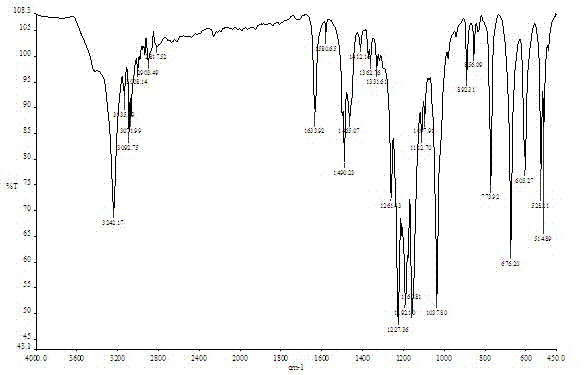

[0018] Example 1: Add 50ml of water, 0.153mol of sodium 3-chloro-2-hydroxypropanesulfonate into a three-necked flask, then drop in 0.304mol of pyridine (1:2), raise the temperature to 94~102°C, keep warm and reflux for 5~10 Hour. After the reaction is complete, pyridine and water are removed under reduced pressure at 80-85°C to obtain a white solid. Add 1.59 mol of formic acid (1:10) to the white solid, filter with suction, add 0.99 mol of methanol (1:6.47) to the obtained filtrate, a large number of crystals are precipitated, filter with suction, and dry in vacuum to obtain high-purity pyridine hydroxypropanesulfonate The onium salt is 0.138mol, the yield is 90%, the sodium chloride content is 0.9%, and the infrared is shown in the accompanying drawing.

[0019] 1 HNMR (D 2 O, 600 MHz): δ 8.806 (d, 2 H, aromatic ring H), 8.544 (t, 1H, aromatic ring H), 8.044 (2H, aromatic ring H), 4.905 (d, OH), 4.471~4.586 ( t, 2H, CH2), 3.185 (t, 2H, CH2), 2.161 (s, 1H, CH).

[0020] ...

Embodiment 2

[0022] Example 2: Add 60ml of water, 0.153mol of sodium 3-chloro-2-hydroxypropanesulfonate into a three-necked flask, then drop in 0.158mol of pyridine (1:1), raise the temperature to 94~102°C, keep warm and reflux for 5~10 Hour. After the reaction is complete, pyridine and water are removed under reduced pressure at 80-85°C to obtain a white solid. Add 2.55m0l of acetic acid (1:17) to the white solid, filter with suction, add 0.71mol of ethanol (1:4.64) to the obtained filtrate, a large amount of crystals are precipitated, filter with suction, and dry in vacuum to obtain high-purity pyridine hydroxypropanesulfonate The onium salt is 0.12mol, the yield is 78.6%, and the sodium chloride content is 0.9%. The infrared is shown in the accompanying drawing.

[0023] 1 HNMR (D 2 O, 600 MHz): δ 8.806 (d, 2 H, aromatic ring H), 8.544 (t, 1H, aromatic ring H), 8.044 (t, 2H, aromatic ring H), 4.905 (d, OH), 4.471~ 4.586 (t, 2H, CH2), 3.185 (t, 2H, CH2), 2.161 (s, 1H, CH2).

[0024]...

Embodiment 3

[0026] Example 3: Add 60ml of water and 0.153mol of sodium 3-chloro-2-hydroxypropanesulfonate into a three-necked flask, then drop in 0.757 (1:4.95)mol of pyridine, raise the temperature to 94-102°C, keep warm and reflux for 5-10 Hour. After the reaction was completed, pyridine and water were removed under reduced pressure at 80-85°C to obtain a white solid. Add 0.78 mol of DMF (1:5) to the white solid, filter with suction, add 0.52 mol of propanol (1:3.39) to the obtained filtrate, a large number of crystals are precipitated, filter with suction, and dry in vacuum to obtain high-purity hydroxypropanesulfonic acid The pyridinium salt is 0.127mol, the yield is 83%, the sodium chloride content is 0.9%, and the infrared is shown in the accompanying drawing.

[0027] 1 HNMR (D 2 O, 600 MHz): δ 8.806 (d, 2 H, aromatic ring H), 8.544 (t, 1H, aromatic ring H), 8.044 (t, 2H, aromatic ring H), 4.905 (d, OH), 4.471~ 4.586 (t, 2H, CH2), 3.185 (t, 2H, CH2), 2.161 (s, 1H, CH2).

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com