Titanium gypsum used in cement, and treatment method thereof by using stalk black ash

A treatment method and technology of titanium gypsum, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of high moisture, inconvenient use, unstable quality, etc., and achieve the effect of good and bad environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0015]

[0016] The present invention uses titanium gypsum to account for its weight 7 ~ 10% calcium carbide slag, and its P H The value is adjusted at 9 or above, and then mixed with a certain proportion of straw black ash to make a certain shape, at 810 + Roasting at 50°C, the desired product will be obtained after calcination, and this product will be named as treated titanium gypsum hereinafter.

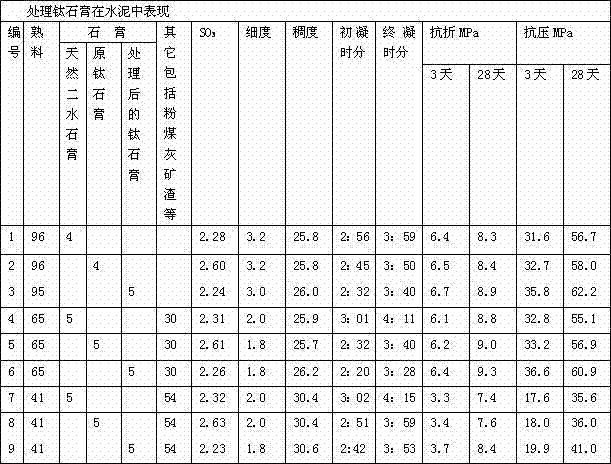

[0017] It is this kind of treated titanium gypsum, whether it is used as a cement coagulant, or a part of it is mixed with natural dihydrate gypsum as a cement coagulant; or a part or most of this treated titanium gypsum is mixed with the original titanium gypsum. As a cement coagulant. The test results show that the hydration strength of cement can be improved to a certain extent no matter it is compared with the test sample that is completely natural dihydrate gypsum as the cement coagulant or with the test sample that is completely the original titanium gypsum as the cemen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com