Intaglio process scraper device

A technology of gravure printing machine and scraper device, which is applied in the direction of gravure rotary printing machine, printing machine, rotary printing machine, etc., which can solve the problems of large change of plate roll, high frequency of occurrence, printing defective products, etc., and achieve stable lateral swing And the effect of flexibility, increased stability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

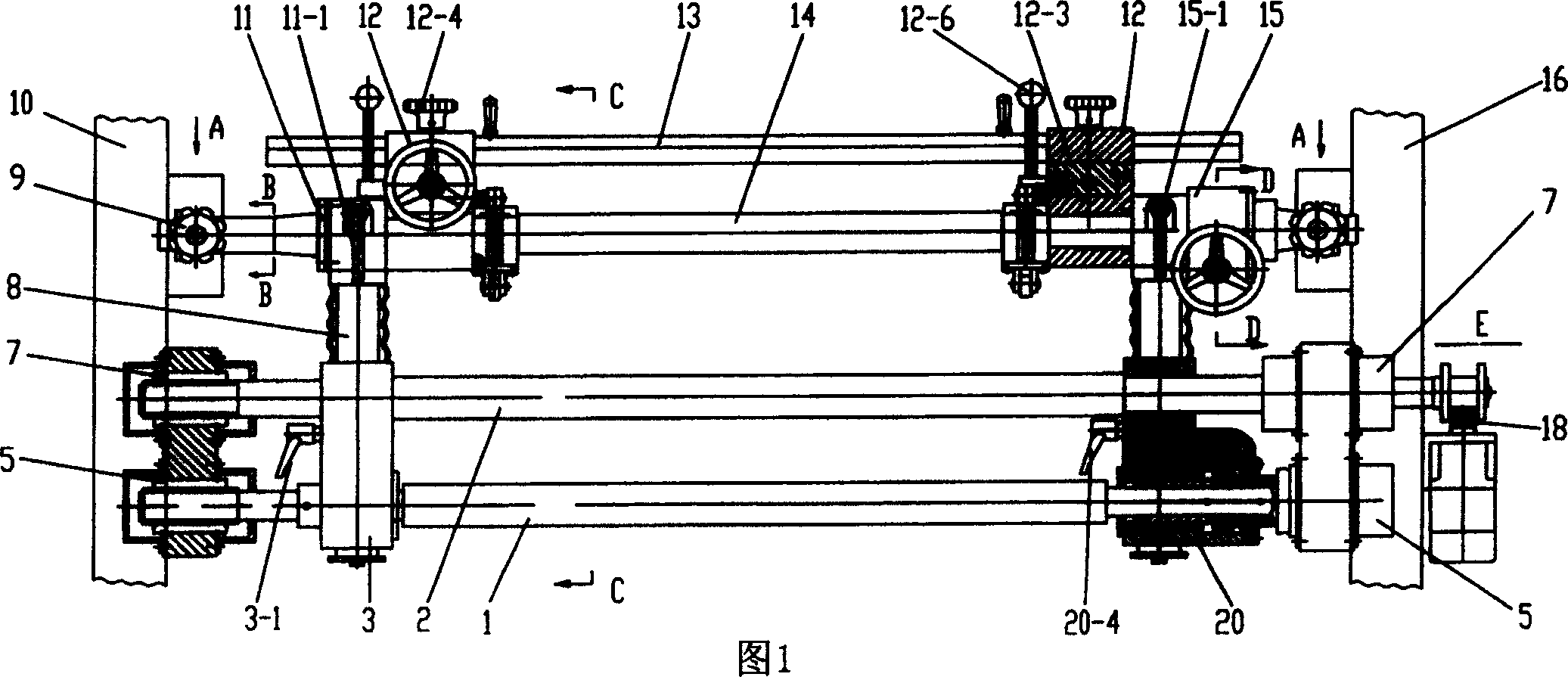

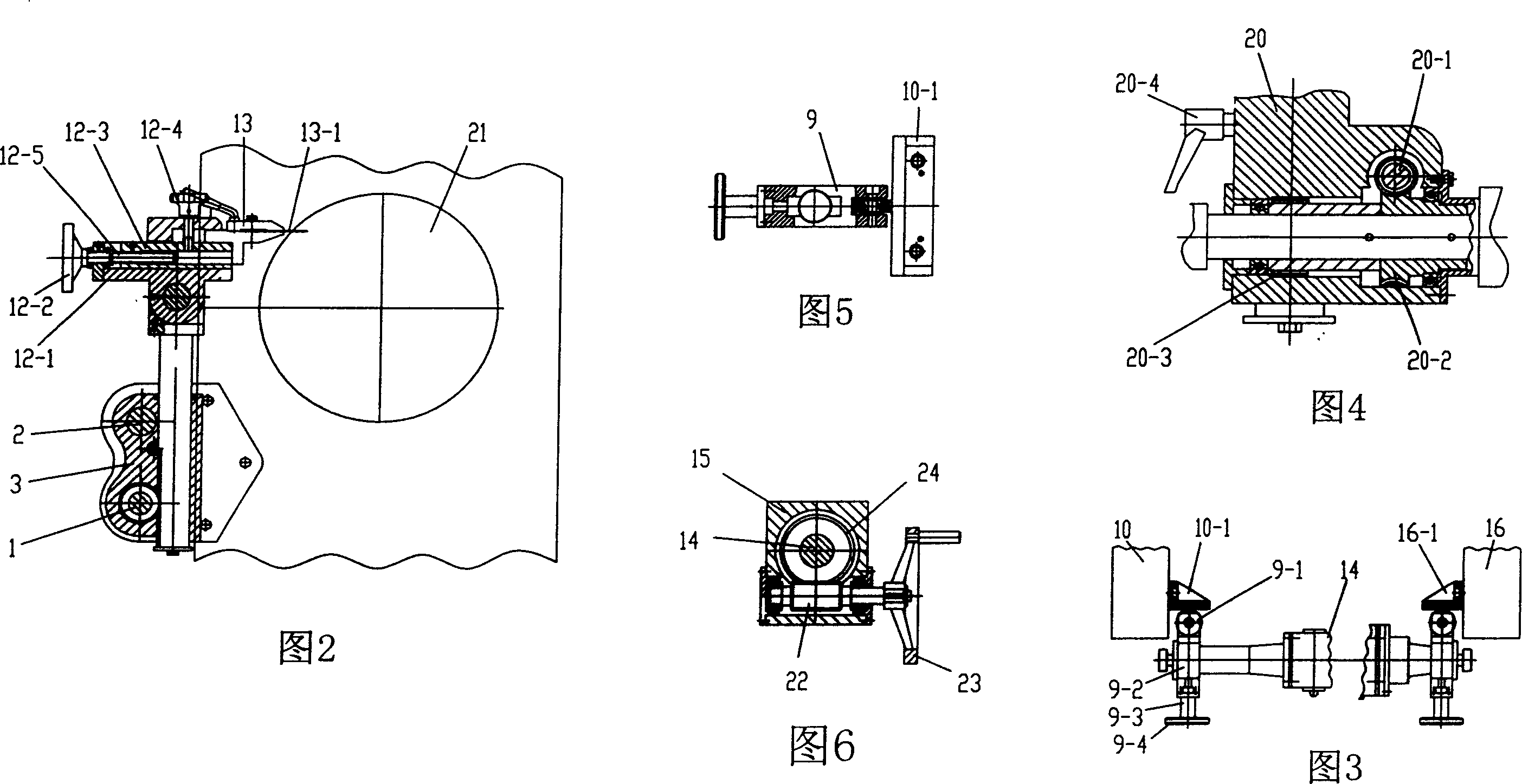

[0019] As shown in Figure 1, the scraper device of the gravure printing machine for decorative coils is provided with a synchronous lifting shaft 1 for scrapers positioned on the wallboards on both sides, and a shaft sleeve 3 and 20 on both sides of the shaft is respectively positioned with a rack. Up and down movement column 8, each bushing has a gear positioned on the synchronous lifting shaft of the scraper and meshed with the rack of the up and down movement column; there is a worm gear mechanism driven by a hand wheel to rotate the gear, and the worm gear 20- 2 is fixed on the scraper synchronous lifting shaft 1, the rotation of the worm 20-1 drives the worm gear 20-2 and the scraper synchronous lifting shaft 1 to rotate, and the synchronous lifting shaft 1 and the gears on both sides of the shaft (the right end is the gear 20-3, the left end gear Omit among the figure) the rotation makes the up and down motion column 8 in the both sides axle sleeve rise or fall.

[0020]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com