Membrane up-flow aerobic bioreactor (MUAR)

An aerobic reactor and reactor technology, which is applied in the field of environmental engineering and wastewater treatment, can solve the problems of not achieving the effect of dissolved oxygen, small contact surface area, and short residence time, so as to improve oxygen transfer and transfer efficiency, specific surface area Large, contact-promoting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

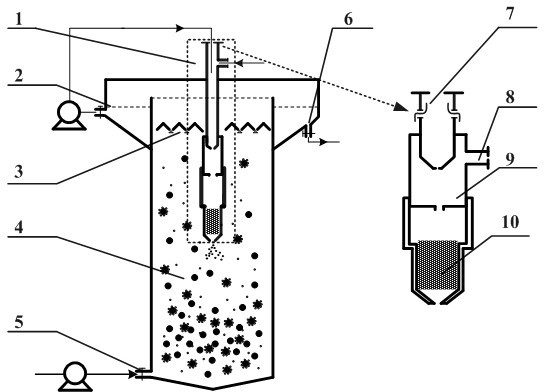

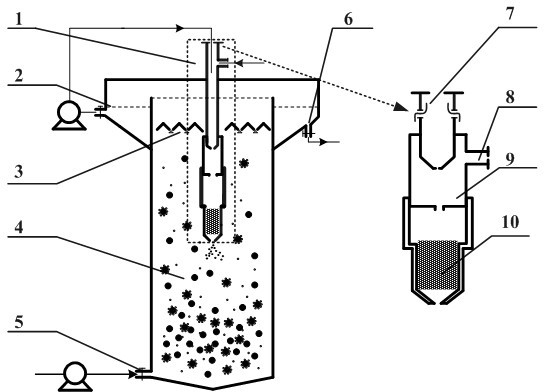

[0012] combined with figure 1 described as follows:

[0013] In order to achieve the above object, the present invention adopts the upflow type aerobic bioreactor ( figure 1 ), the material of the reactor is stainless steel or tempered glass, and the aspect ratio is 2:1-8:1. Among them, the ultra-fine bubble generator (1) is composed of jet aeration water inlet (7), air inlet (8), decompression chamber (9) and microporous filter tube (10), wherein the air outlet of the bubble generator extends Into the inside of the reactor (4) below the mud-water separation baffle (3). In addition, the microporous filter tube in the ultrafine bubble generating device of the present invention can be replaced to facilitate cleaning and maintenance.

[0014] The water inlet mode of the aerobic reactor is an upflow water inlet (5), the upper part of the reactor is provided with a mud-water separation baffle made of polypropylene (3), and the top of the reactor is provided with an effluent back...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com