Coiled material conveying tensioning device

A tensioning device and tensioning technology, applied in the direction of winding strips, transportation and packaging, thin material handling, etc., can solve the problems of affecting the progress of the production process, intricate rollers, time-consuming and laborious, etc., to avoid poor guiding movement, Responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

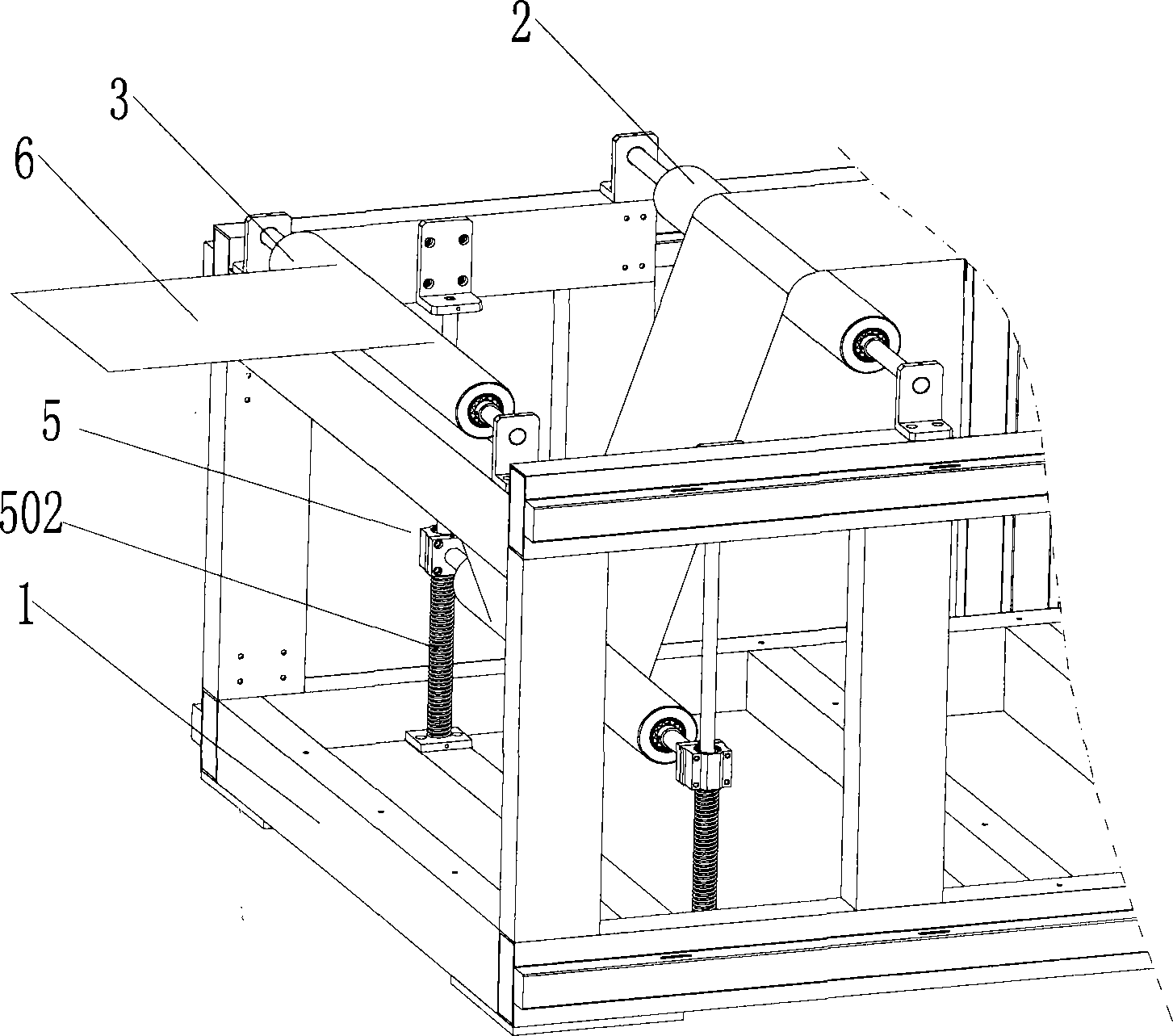

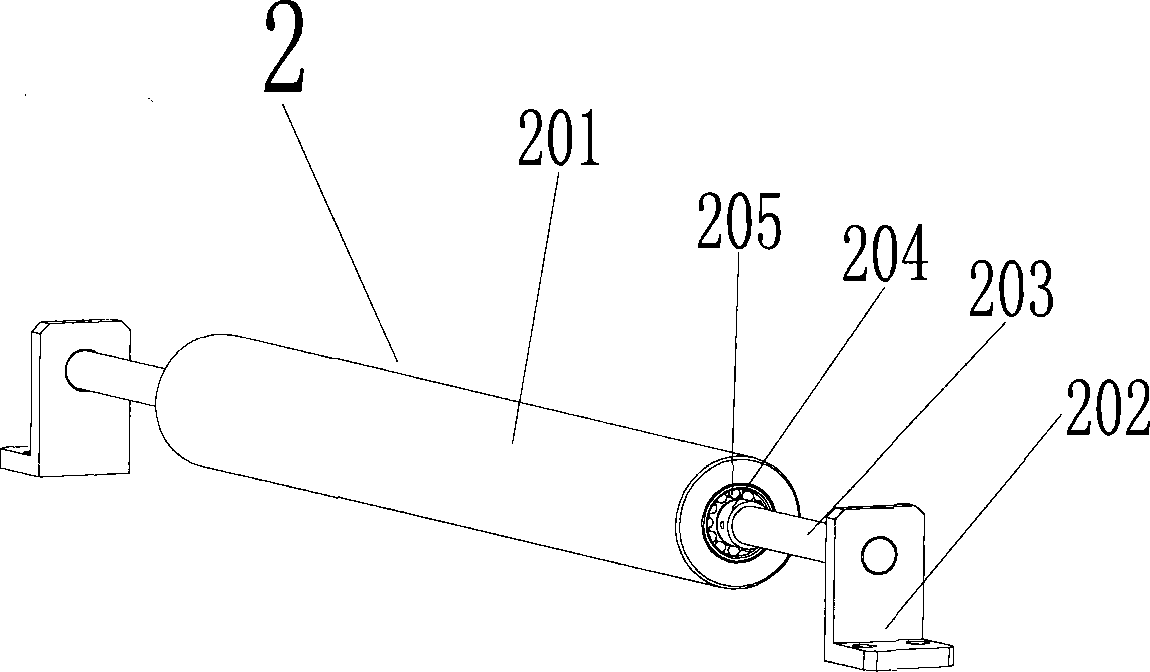

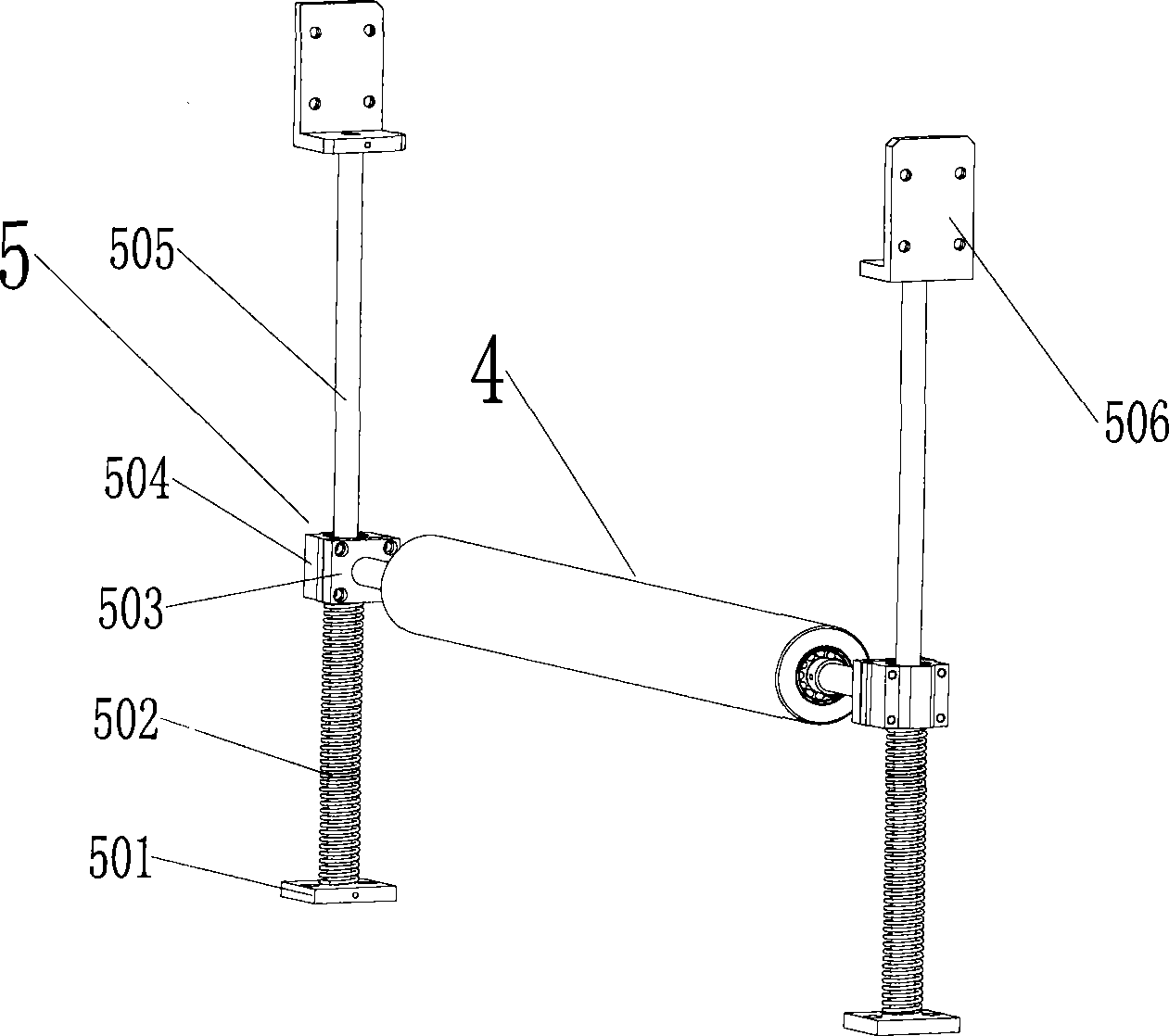

[0032] Such as figure 1 As shown, in this embodiment, the coil conveying tensioning device includes a workbench support 1 and a first guide roller assembly 2, a second guide roller assembly 3, and a tension guide roller assembly arranged on the workbench support 1. 4 and the tension guide roller bracket assembly 5, the first guide roller assembly 2 and the second guide roller assembly 3 are arranged on the upper part of the workbench bracket, and the tension guide roller bracket assembly 5 is arranged on the first Between the guide roller assembly 1 and the second guide roller assembly 2 , both ends of the tension guide roller assembly 4 are erected on the tension guide roller bracket assembly 5 . The axes of the first guide roller assembly 2 , the second guide roller assembly 3 and the tension guide roller assembly 4 are parallel.

[0033] The first guide roller assembly includes a first guide roller, the second guide roller assembly includes a second guide roller, the tensi...

Embodiment 2

[0050] Such as Figure 11 As shown, the structure of the coil conveying tensioning device in this embodiment is basically the same as that in Embodiment 1, the difference is that: the tension guide roller support assembly 5 also includes two limit switches 509, the Two limit switches 509 are respectively set on the guide rod 505 corresponding to the maximum tension position and the maximum compression position of the spring 502 . In this way, when the spring 502 reaches the maximum tension position or the maximum compression position, the limit switch 509 will prevent the tension guide roller assembly 4 from further moving upwards or downwards, so as to prevent the coil 6 from being broken.

[0051] Other structures in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

[0052] From the above detailed description of the embodiments of the present invention, it can be understood that the present invention solves the problems of complex tensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com