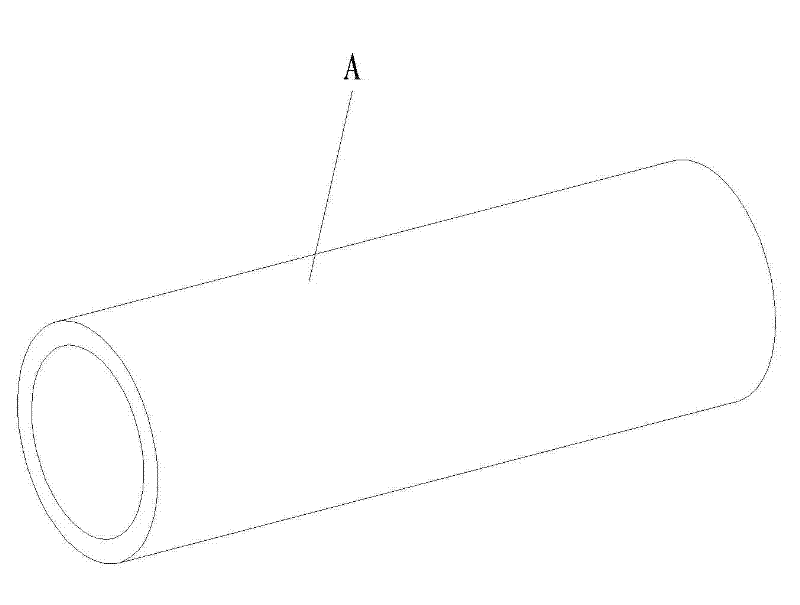

Diamond wire saw connecting device

A technology of diamond wire saw and connection device, which is applied in the direction of sawing machine tools, metal sawing equipment, metal processing equipment, etc., which can solve the problems of disengagement and fracture of joints, and achieve the effect of reasonable structure and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

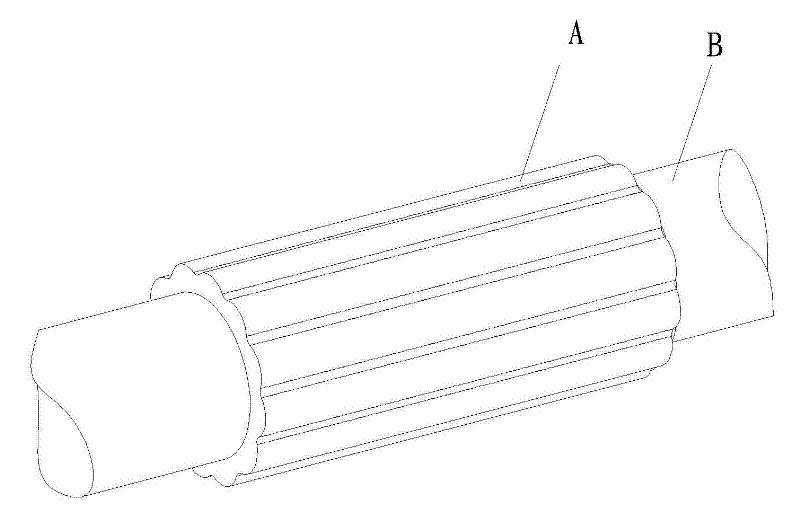

[0053] Fix the diamond wire saw that has been injected with rubber and plastic elastomer, and fix one end of the diamond wire saw head or tail, and twist it in the opposite direction for several weeks (the purpose is to rotate by itself during cutting, so as to ensure that the main directions of the diamond beads are worn evenly during cutting. ), degrease the head and tail of the wire rope in the diamond wire saw and set it aside. Connect the socket with bevel space on both sides (bevel 4 of the end face of the socket) (such as Figure 5 , Image 6 As shown), the outer diameter is 2.4mm, the inner diameter is 1.7mm, and the length is 20mm. The sides are degreased for later use; the rubber and plastic elastic body 5 on the head and tail wire rope 3 is adjusted to keep a certain length. Heat the joint sleeve 1 to 150°C, put the wire rope 3 head and tail into the joint sleeve, extrude the plastic cylinder layer whose outer diameter is larger than the inner diameter of the joint...

Embodiment 2

[0055] String the diamond beads 13 with a diameter of φ2.8mm into the steel wire rope with a diameter of φ1.6mm, and inject the rubber-plastic elastomer 5 (we use PV material) through the injection molding machine to the spacer area of the diamond beads, that is, the outer surface of the steel wire rope. The round part is made into an unclosed diamond wire saw. For this, the head and tail of the diamond wire saw are reversed for a few weeks (the purpose is to rotate by itself during cutting to ensure that the main directions of the diamond beads are worn evenly during cutting), and then put the head and tail of the diamond wire saw into the joint sleeve (see Figure 17 ), and then press the two ends with hydraulic pliers, but keep at least 2MM on the two sides of the two ends without pressing, leaving a space filled with rubber and plastic elastomers in the inner circle. Put the joint cover that has been pressed tightly into the injection mold, and use the injection molding ...

Embodiment 3

[0056] Embodiment 3 adopts a joint sleeve with dovetail grooves on both sides, which is used to connect the two ends of the head and tail of the diamond wire saw. Other steps are the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com