Method for flushing inner ring oil supply holes of rotor of bearing utilizing inner ring oil supply for lubricating

A technology of oil supply hole and front axle, which is applied in the flushing field of the oil supply hole under the rotor ring, which can solve the problems that conventional means cannot be cleaned, the flushing is difficult, and there is oil stains, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

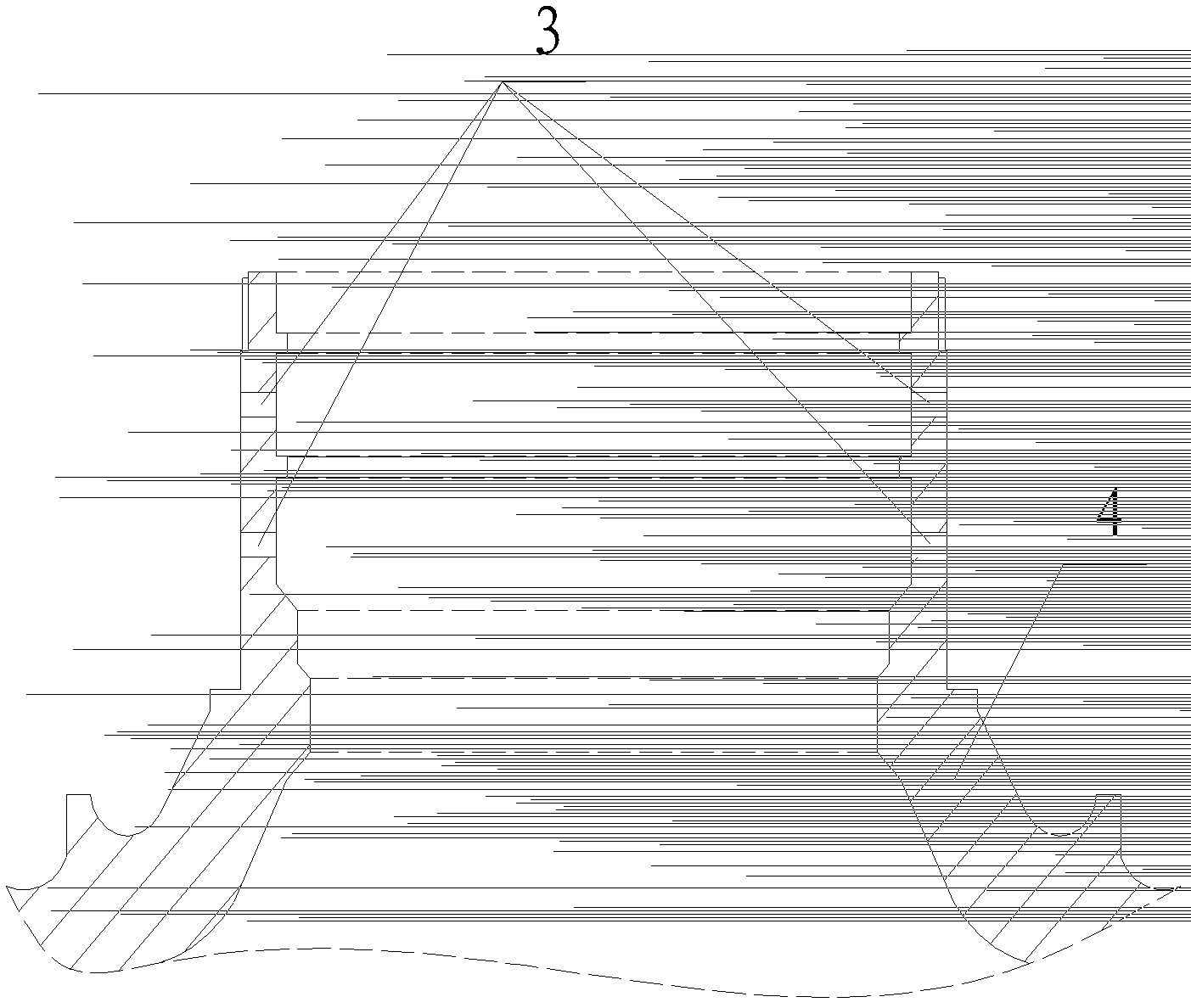

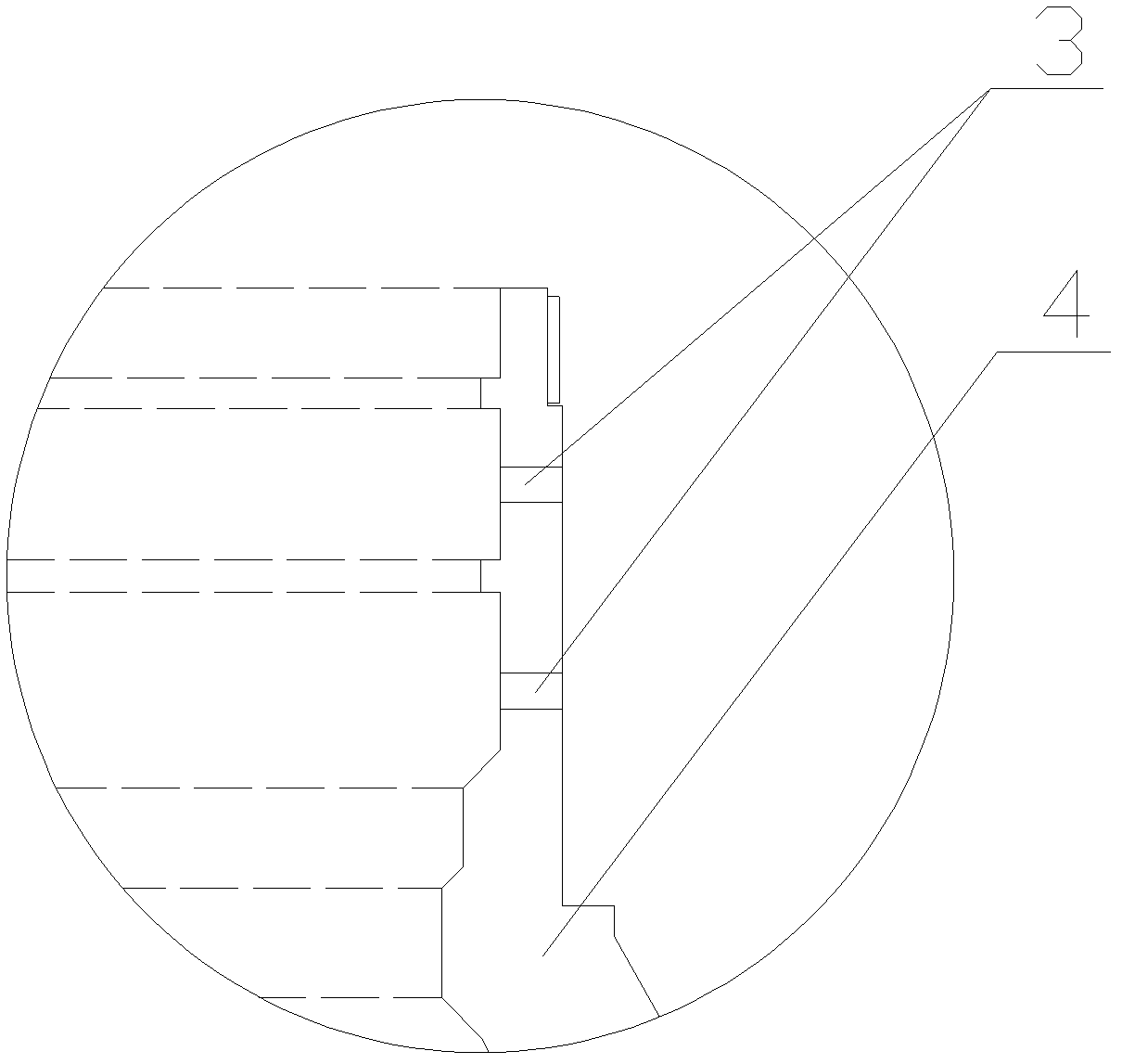

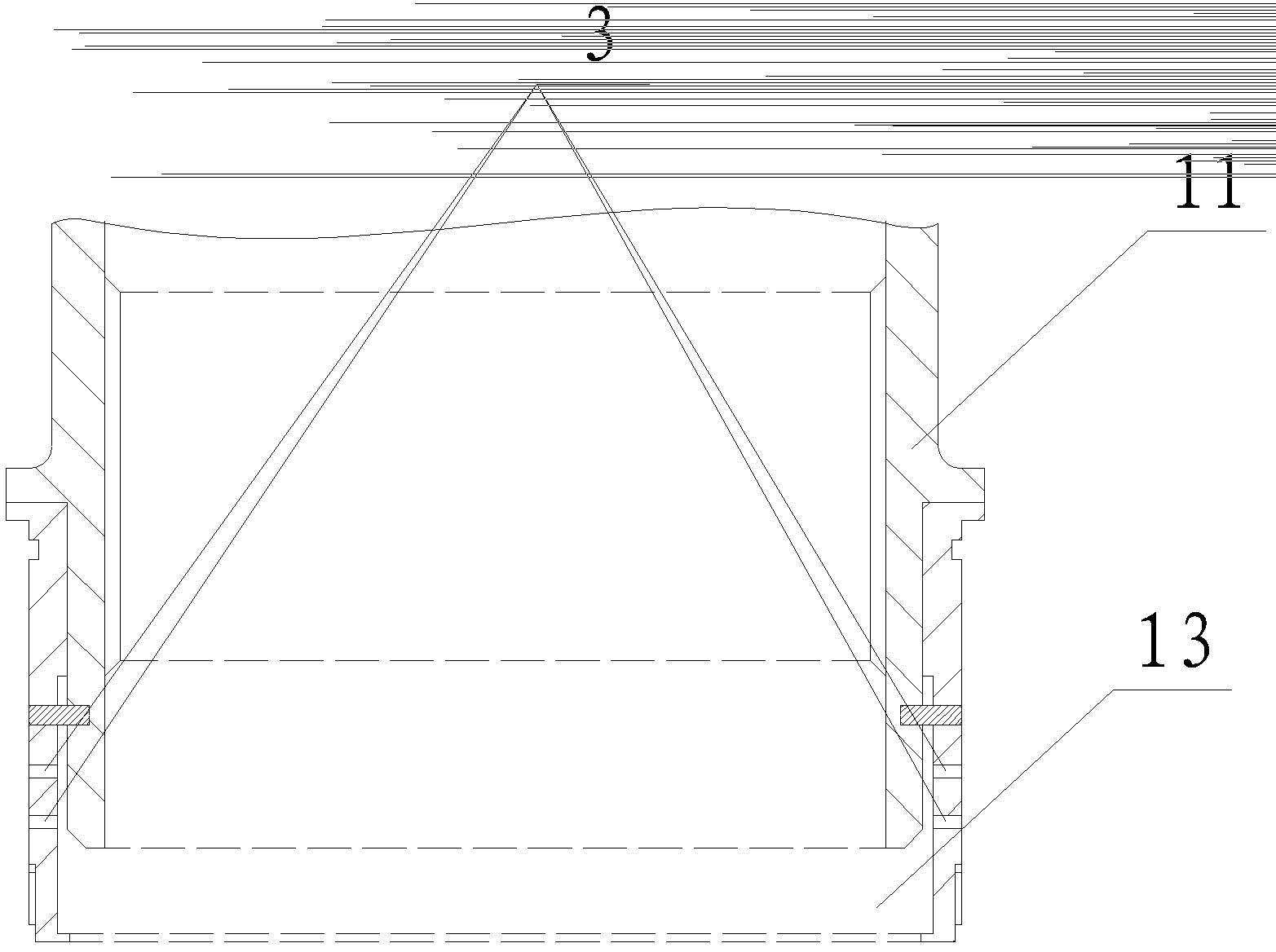

[0032] A method for flushing the oil supply hole under the rotor ring of a bearing that is lubricated by oil supply under the ring. The method for flushing the oil supply hole under the front journal ring in the oil supply hole under the ring is as follows: Figure 5 , Figure 6 shown, including the following steps:

[0033] Step 1: Place the front journal 4 to be flushed horizontally to ensure oil return collection;

[0034] Step 2: install an annular oil collection chamber 5 with an oil return port 9 on the inner side of the front journal 4;

[0035] Step 3: install an oil collector ring 6 with an oil inlet 10 on the outer side of the oil supply hole 3 under the ring of the front journal 4, and fix the oil collector ring 6 on the front journal 4 by pressing the nut 7;

[0036] Step 4: Connect the oil return port 9 of the annular oil collection chamber 5 with the oil return pipe 8 of the tester 12 (LS230), connect the oil inlet 10 of the oil collection ring 6 with the oil i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com