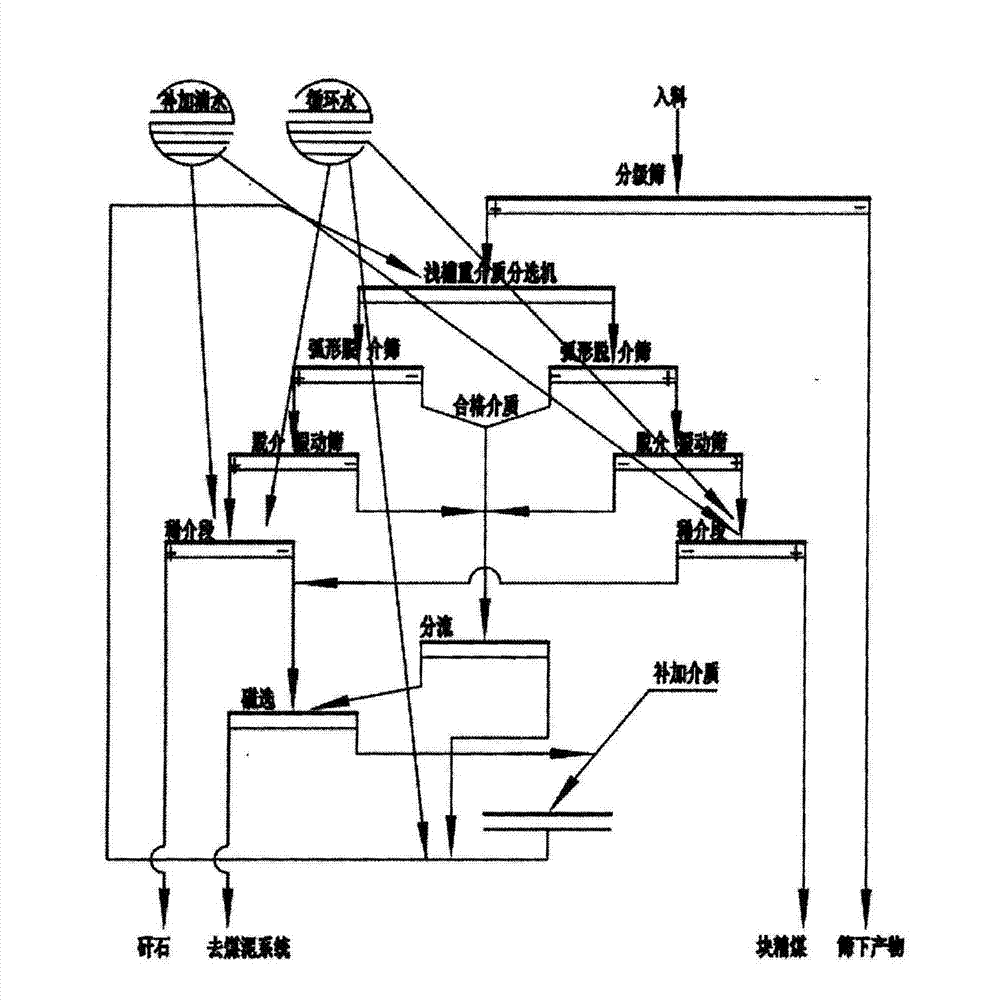

Integrally designed two-product dense medium separation process

A dense medium and sorting technology, applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of increasing system power, reducing system reliability, increasing system process links, etc., to save space and density The effect of stability and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

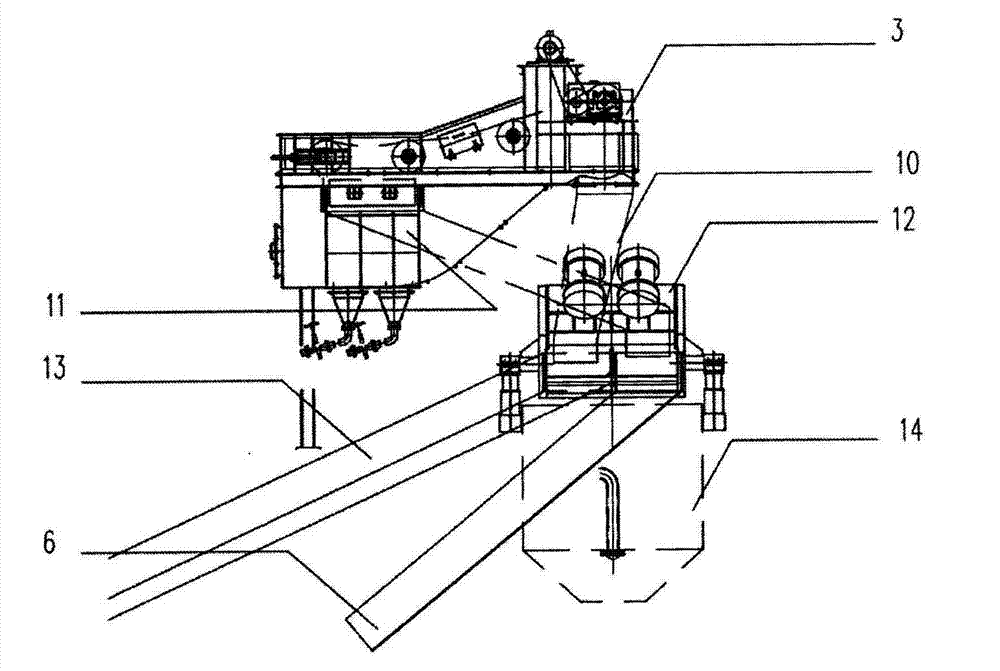

[0034] Aiming at the characteristics of low coal slime content in jigging gangue coal flow, the present invention proposes an integrated two-product dense medium separation process, that is, the traditional shallow groove dense medium separation process is highly integrated to make it It is suitable for the re-election of gangue washing, especially for the technical transformation of coal preparation plants for re-election of jigging gangue.

[0035] Technical scheme of the present invention is summarized as follows:

[0036]The main technical features of the present invention are: ① The traditional vertical discharge method of light and heavy products should be discharged in the same direction, so that light and heavy products can share the same fixed sieve and linear vibrating sieve for separation, and the middle of the sieve is separated by a partition; ②Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com