Active carbon filter plant for producing amino acid

A technology of activated carbon filtration and amino acid, which is applied in the direction of loose filter material filter, filtration separation, gravity filter, etc., can solve the problems of affecting recycling and cannot be cleaned, and achieve the effect of improving quality and improving filtration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the description of the drawings and specific embodiments, but the scope of protection of the present invention is not limited to the following examples.

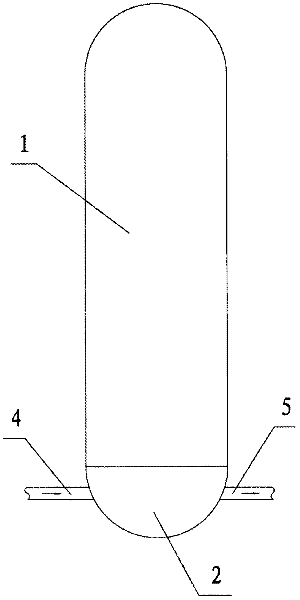

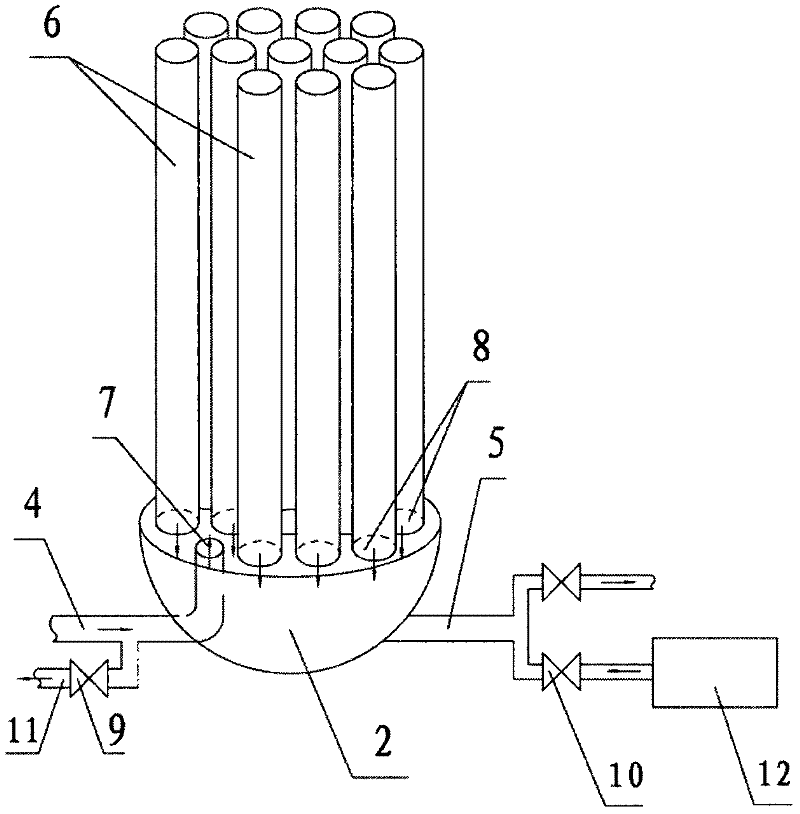

[0015] Such as figure 1 , 2 As shown, an activated carbon filter device for amino acid production, comprising a main cavity 1, a base cavity 2, an input pipe 4, and an output tube 5, with a partition between the main cavity 1 and the base cavity 2; There is a hole 8 on the partition, and at least one filter element 6 is placed in the main cavity 1. The filter element 6 is adapted to the hole and communicates with the base cavity 2. The filter element 6 is a single-ended closure. In the present embodiment, the filter element 6 is a titanium metal tube with sieve holes on the tube wall of the titanium metal tube. The mesh size of the sieve holes is designed according to the type and size of impurities to be filtered in the liquid.

[0016] The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com