Biological pre-treatment freshness-keeping method for green vegetable heads

A technology of biological pretreatment and fresh-keeping method, which is applied in the field of biological pretreatment and fresh-keeping of cabbage heads, can solve the problems of product safety hazards in the production process, restrict the stable and continuous development of the industry, and unfavorable industrial scale production, etc., and achieve simple and easy operation methods, It is conducive to industrial scale production and has no potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

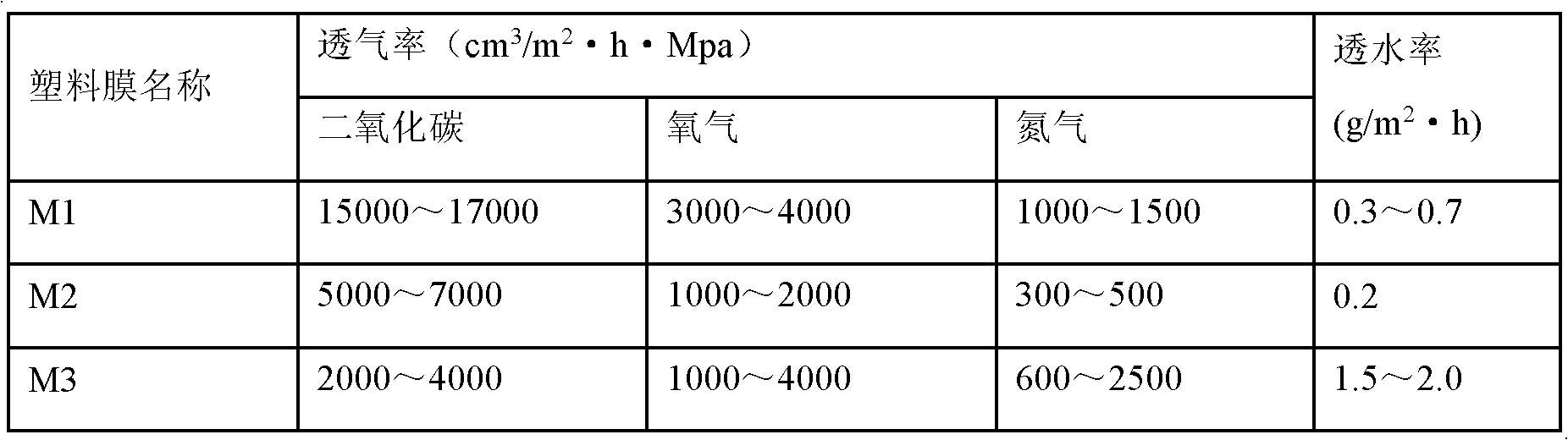

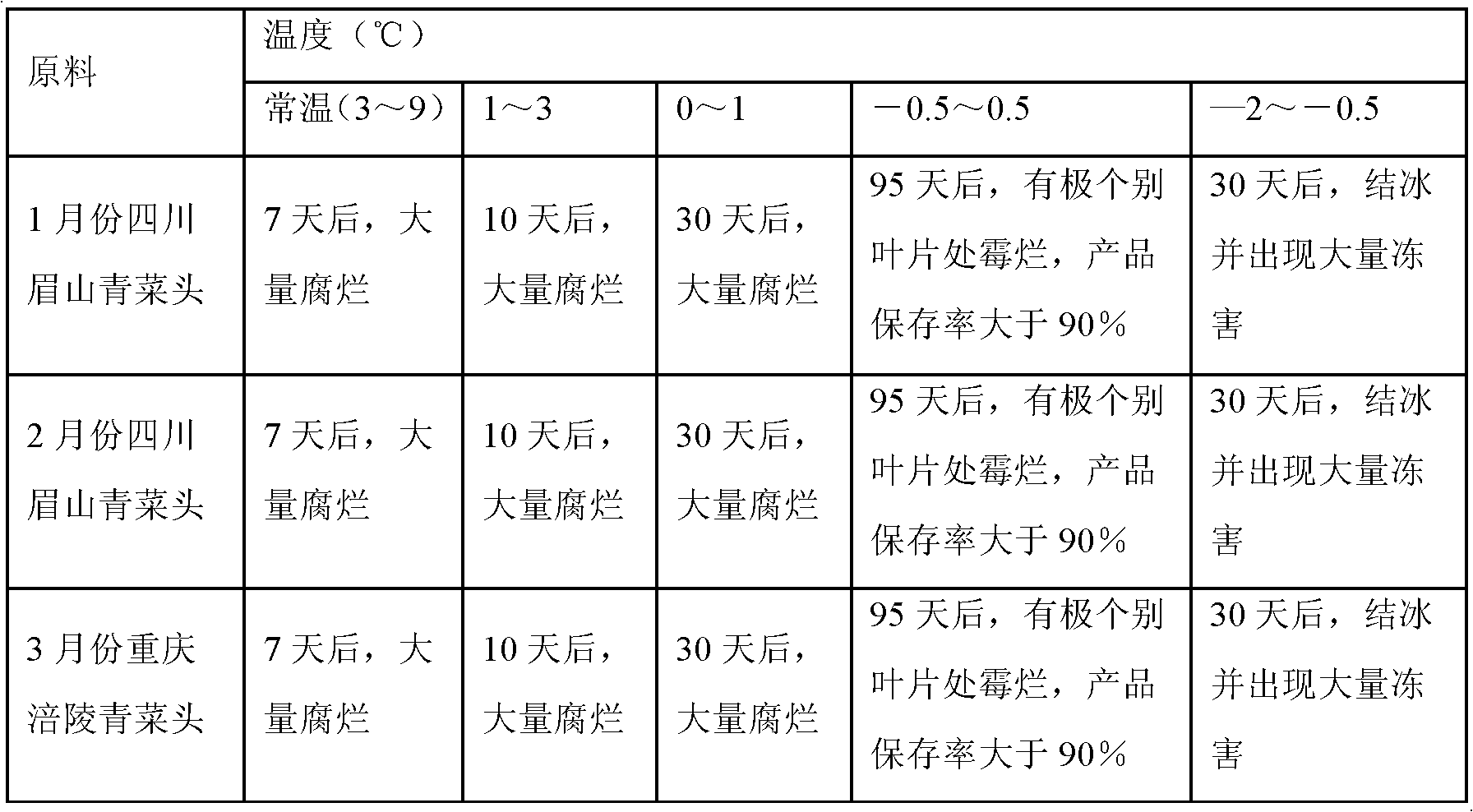

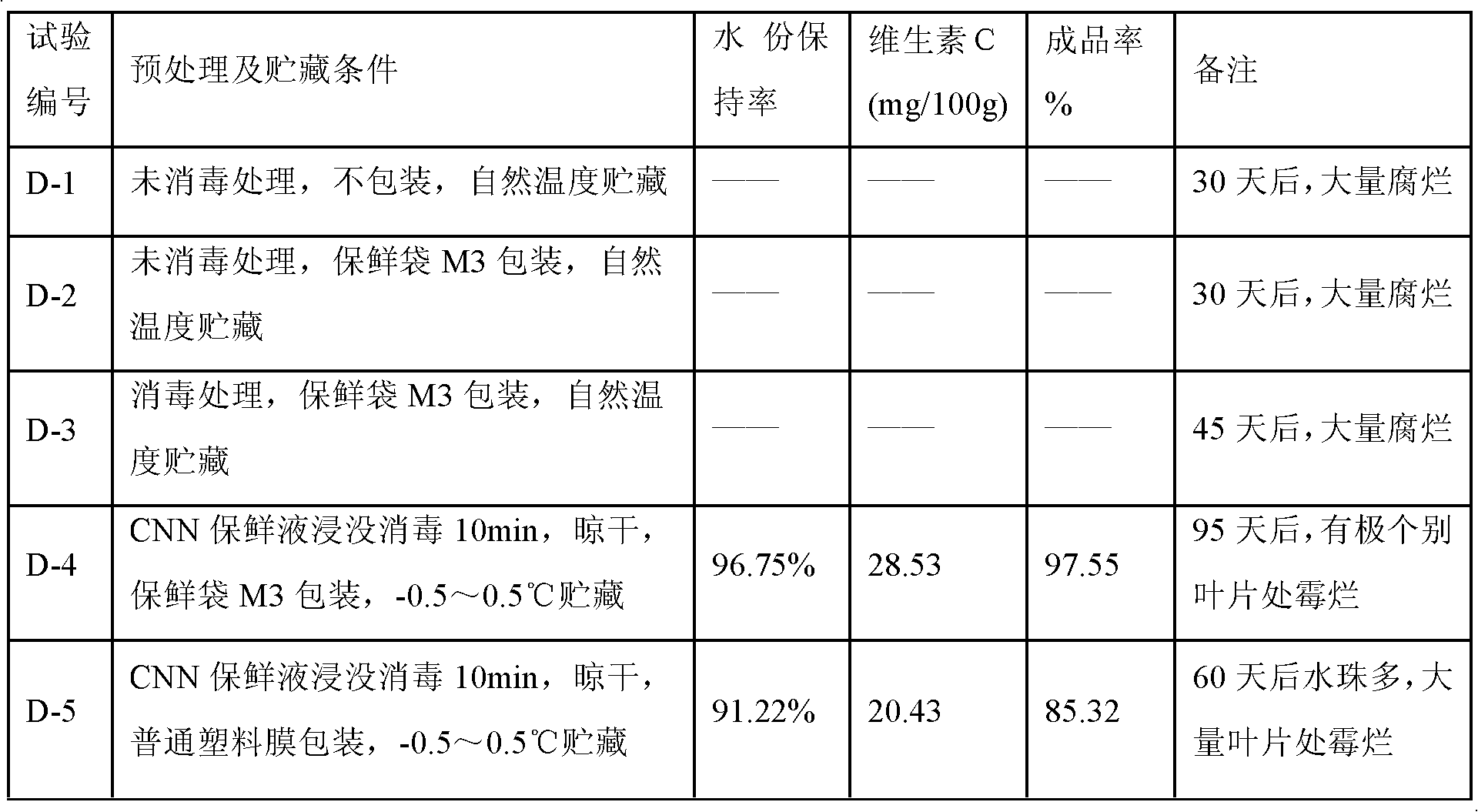

Method used

Image

Examples

Embodiment 1

[0013] A biological pretreatment and fresh-keeping method of cabbage head, it comprises the following steps:

[0014] (1) Pretreatment: Carry out selection inspection, cleaning and disinfection treatment to the cabbage heads;

[0015] (2) fresh-keeping treatment: immerse the pretreated green cabbage head in CNN composite fresh-keeping liquid, carry out fresh-keeping treatment, and keep fresh-keeping treatment for 8 minutes;

[0016] (3) Refrigeration: Take out the green cabbage heads after fresh-keeping treatment, put them into self-generating modified atmosphere M3 film preservation bags after drying, put 4.5kg green cabbage heads in each modified atmosphere M3 fresh-keeping bag, seal them, and store them at -0.5°C 90 days;

[0017] Wherein, the CNN composite fresh-keeping solution is composed of the following components and percentage by weight: 0.005% chlorine dioxide, 0.005% natamycin, 0.03% sodium dehydroacetate, and the balance is water.

Embodiment 2

[0019] A biological pretreatment and fresh-keeping method of cabbage head, it comprises the following steps:

[0020] (1) Pretreatment: Carry out selection inspection, cleaning and disinfection treatment to the cabbage heads;

[0021] (2) fresh-keeping treatment: immerse the pretreated green cabbage head in the CNN composite fresh-keeping liquid, carry out fresh-keeping treatment, and keep fresh-keeping treatment for 12 minutes;

[0022] (3) Refrigeration: Take out the green cabbage heads after fresh-keeping treatment, put them into self-generating modified atmosphere M3 film preservation bags after drying, put 5.5kg green cabbage heads in each modified atmosphere M3 fresh-keeping bag, seal them, and store them at 0°C for 100 sky;

[0023] Wherein, the CNN composite fresh-keeping solution is composed of the following components and percentage by weight: 0.01% chlorine dioxide, 0.01% natamycin, 0.01% sodium dehydroacetate, and the balance is water.

Embodiment 3

[0025] A biological pretreatment and fresh-keeping method of cabbage head, it comprises the following steps:

[0026] (1) Pretreatment: Carry out selection inspection, cleaning and disinfection treatment to the cabbage heads;

[0027] (2) fresh-keeping treatment: immerse the pretreated green cabbage head in CNN composite fresh-keeping liquid, carry out fresh-keeping treatment, and keep fresh-keeping treatment for 10 minutes;

[0028] (3) Refrigeration: Take out the green cabbage heads after fresh-keeping treatment, put them into self-generating modified atmosphere M3 film preservation bags after drying, put 5 kg of green cabbage heads in each modified atmosphere M3 fresh-keeping bag, seal them, and store them at 0.5°C for 95 days ;

[0029] Wherein, the CNN composite fresh-keeping liquid is composed of the following components and percentage by weight: chlorine dioxide 0.015%, natamycin 0.015%, sodium dehydroacetate 0.02%, and the balance is water.

[0030] The following is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com