Life test method of magnetic-pulse forming inductor

A magnetic pulse forming and life test technology, applied in the direction of testing dielectric strength, etc., can solve the problems of increased test cost, complicated design and manufacturing process, and large waste, and achieve the effect of saving test cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

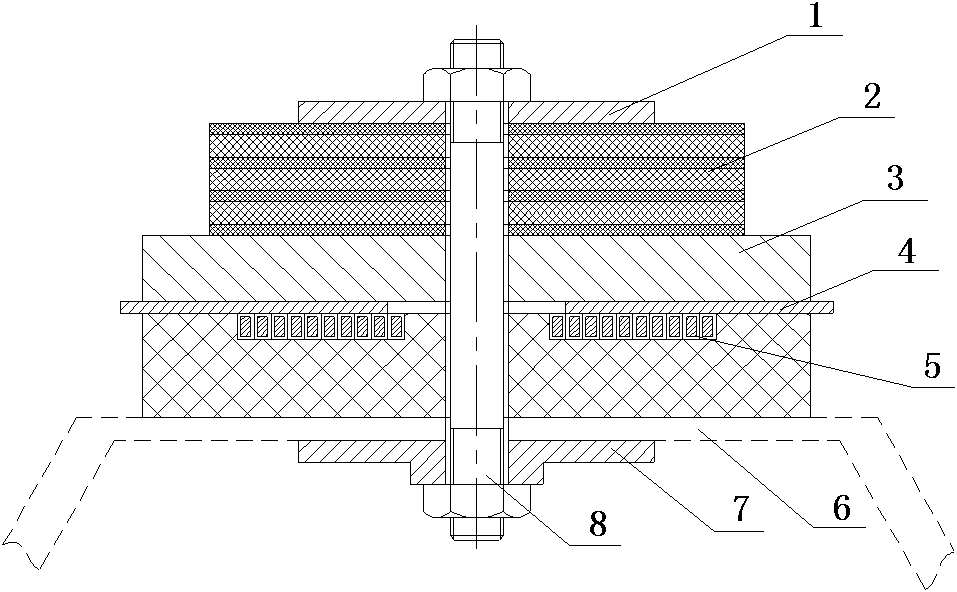

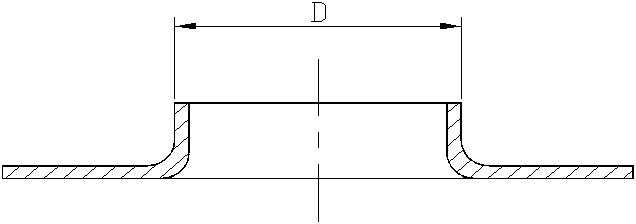

[0033] Such as figure 1 Shown: The components and functions of the magnetic pulse forming inductor life equivalent test device: the pressure plate 1 acts as a gasket and plays the role of pressing the rubber pad 2, which can be ordinary Q235 steel plate with a thickness of 8-10mm; the rubber pad 2 is 30mm thick or multi-layer cumulative thickness of 30mm can be used, the Shore hardness is between 30-50 degrees; the support plate 3 plays a supporting role to prevent the deformation of the test piece 4, and the material can be ordinary Q235 steel plate or aluminum alloy, with a thickness of 20-30mm That’s it; the test piece 4 is a flat plate blank, which can be determined according to actual needs; the support 6 has a load-bearing function and is made of ordinary Q235 steel plates; the backing plate 7 is an ordinary Q235 steel plate; the materials and diameters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com