Wheel Drive Control Device, Wheel Drive Control Method, And Program Therefor

A technology of driving control and wheels, applied in the direction of transportation and packaging, load suspension components, etc., to achieve the effect of reducing wheel idling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Next, a wheel drive control device according to an embodiment of the present invention will be described with reference to the drawings.

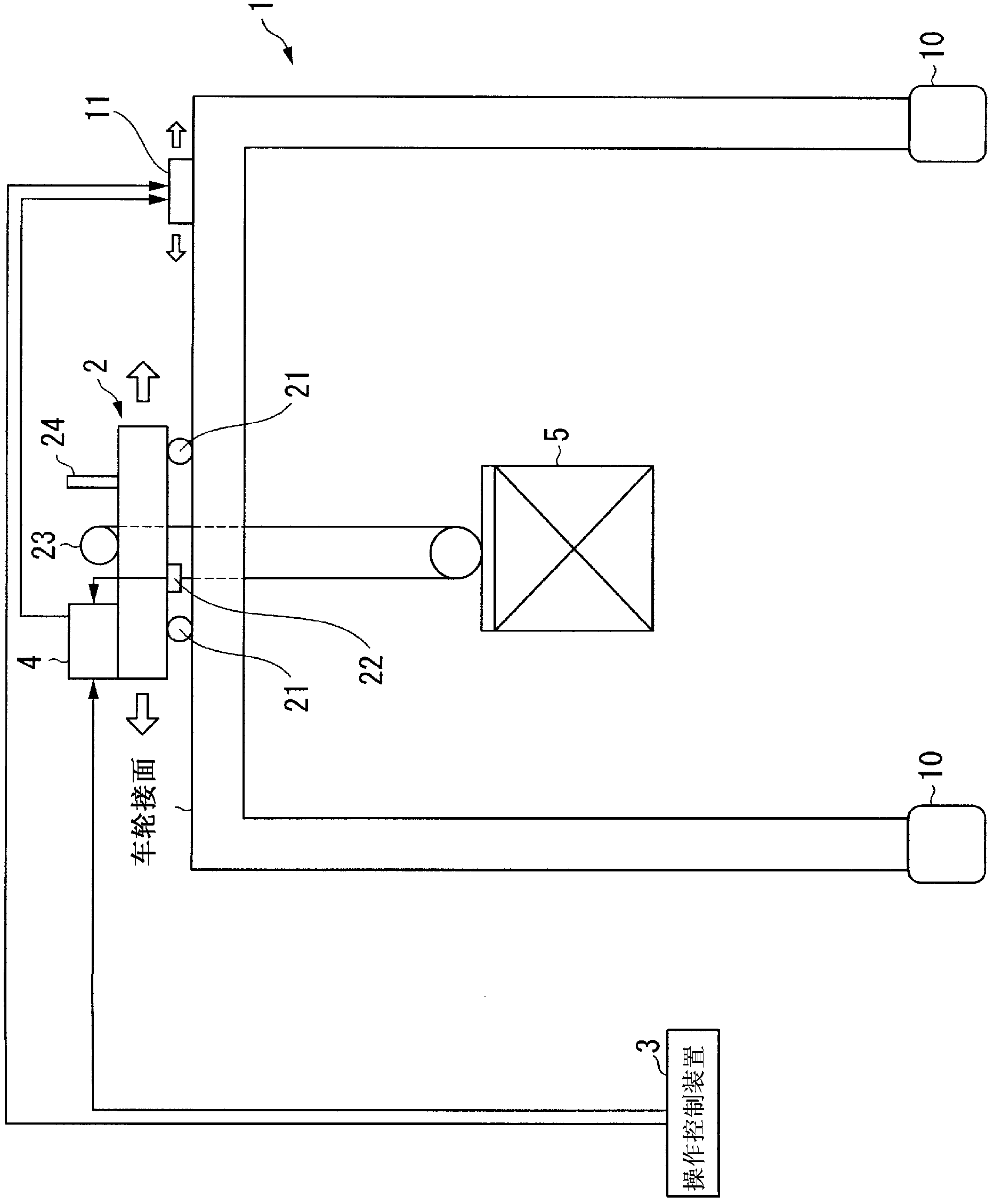

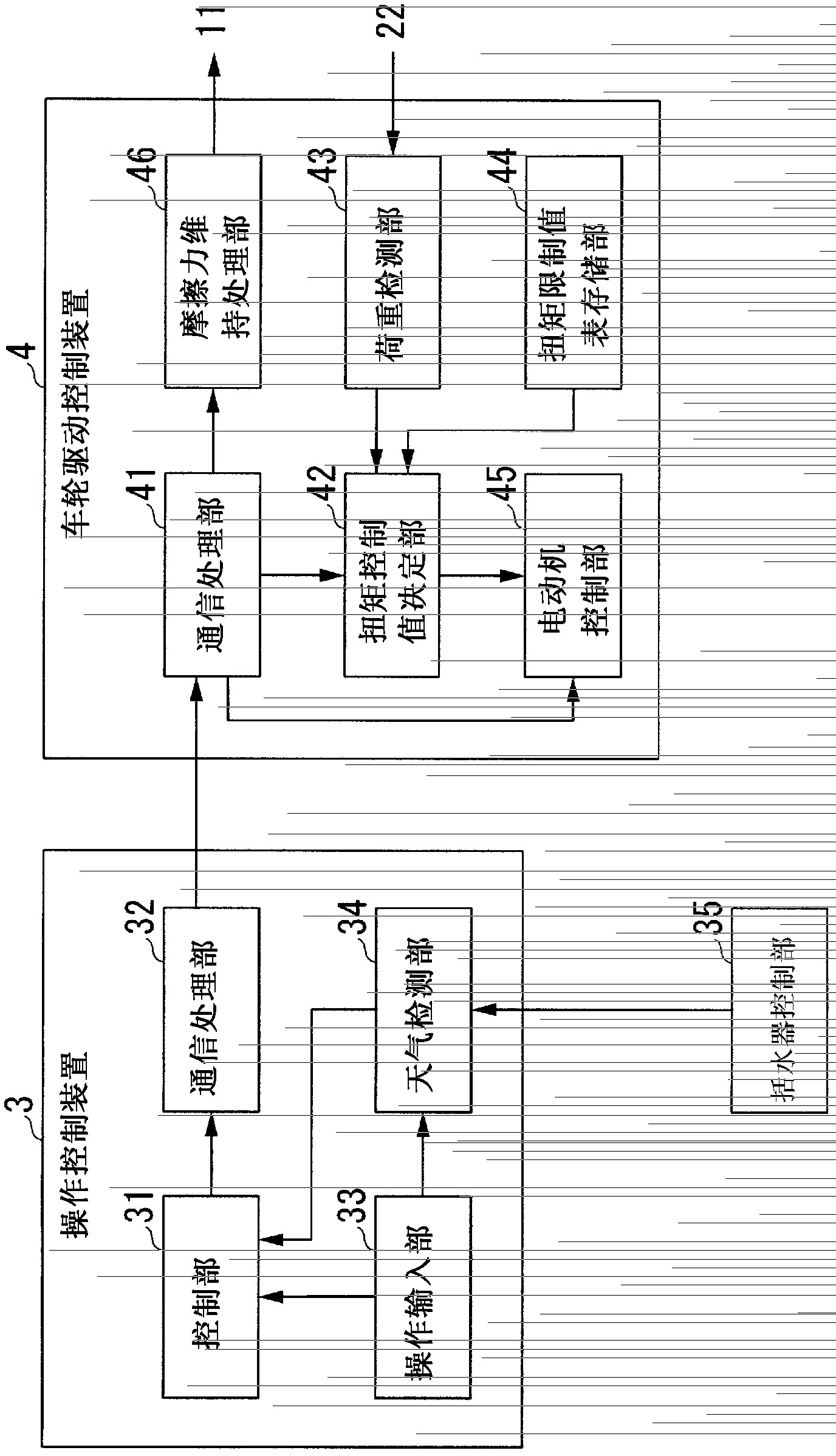

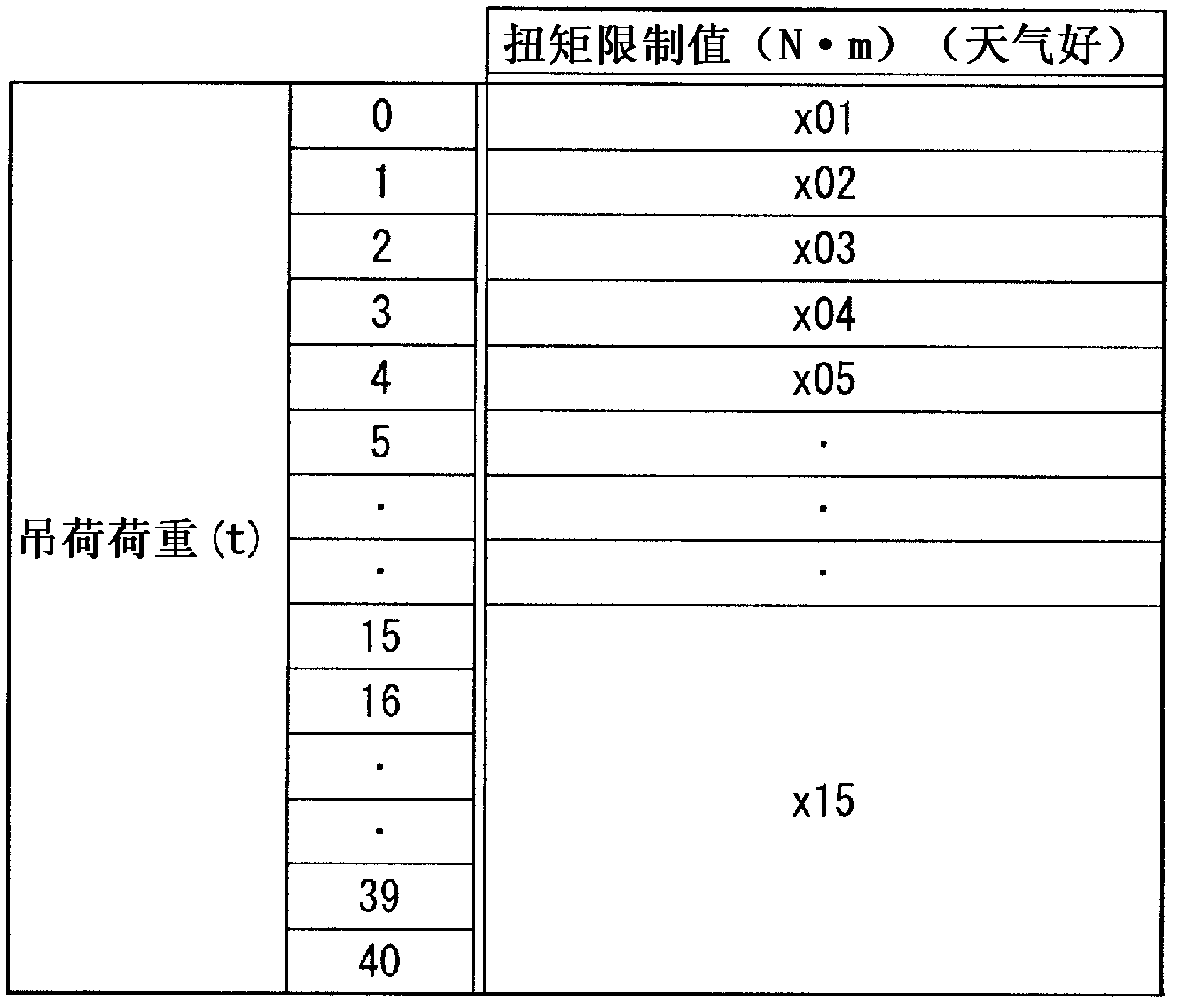

[0051] figure 1 It is a block diagram showing the structure of the crane equipped with the wheel drive control apparatus of the same embodiment.

[0052] In this figure, symbol 1 is a crane. On the crane 1, a load block 2 is installed above. The trolley 2 moves (travels) on a rail provided above the crane 1, for example. Furthermore, the crane 1 itself has wheels 10 , and can travel by driving the wheels 10 of the crane 1 . In addition, the trolley 2 is equipped with at least: a wheel 21 in contact with a wheel such as a rail, a wheel drive control device 4 for controlling the driving of the wheel 21, a hoisting portion 23 for moving the suspension 5 up and down, and a detection suspension. The load meter 22 of the load. In addition, the trolley 2 may be provided with an anemometer 24 .

[0053] In addition, the crane 1 has an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com