Continuous motion inline feeder

A continuous motion, feeder technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as difficult adjustment and limiting product throughput.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

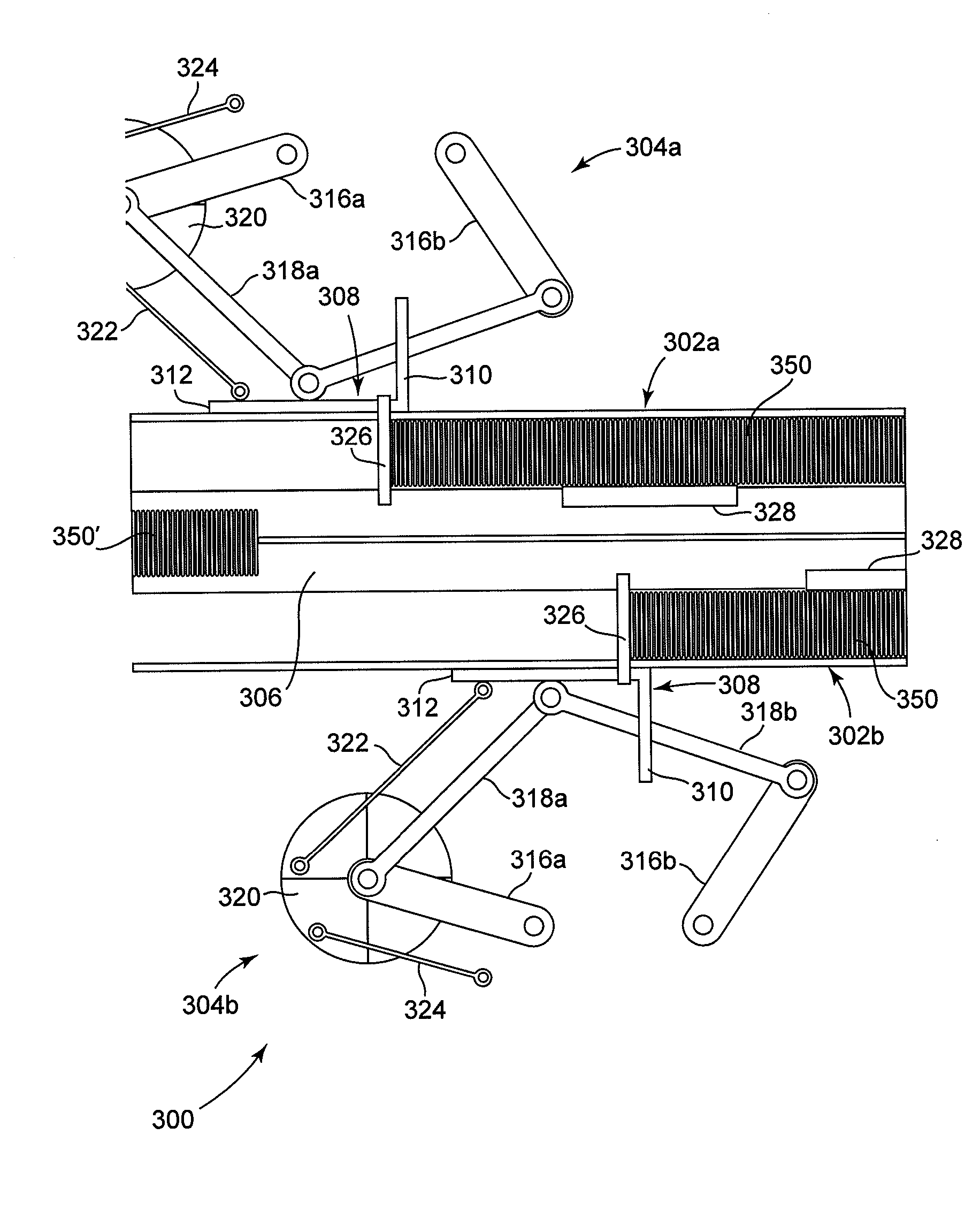

[0023] Various embodiments of the present disclosure will be described in detail with reference to the drawings, wherein like reference numerals indicate like parts and assemblies. Reference to various embodiments does not limit the scope of the invention, which is limited only by the scope of the claims appended hereto. Furthermore, any examples set forth in this specification are not intended to be limiting but merely illustrative of some of the many possible embodiments for the claimed invention.

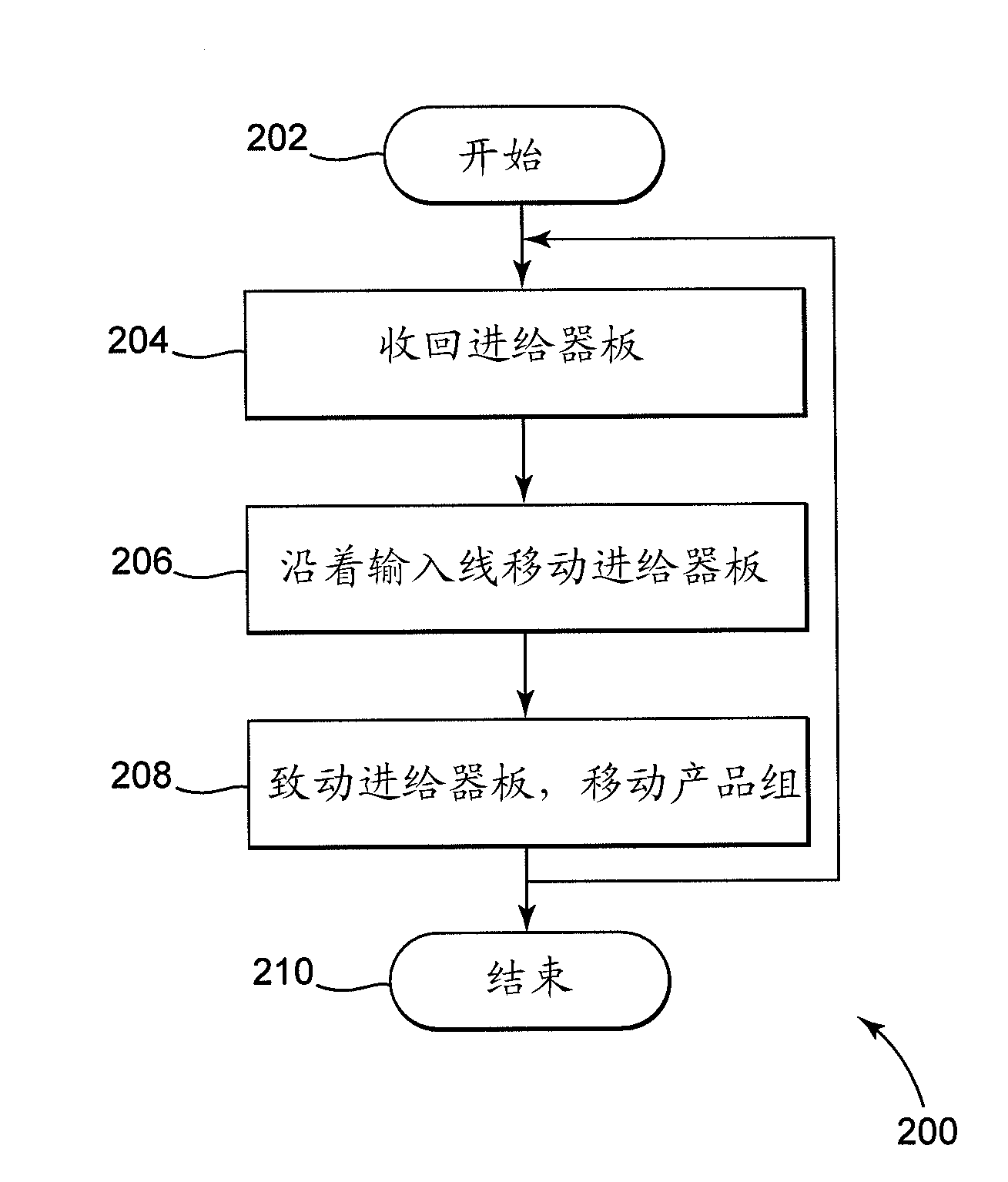

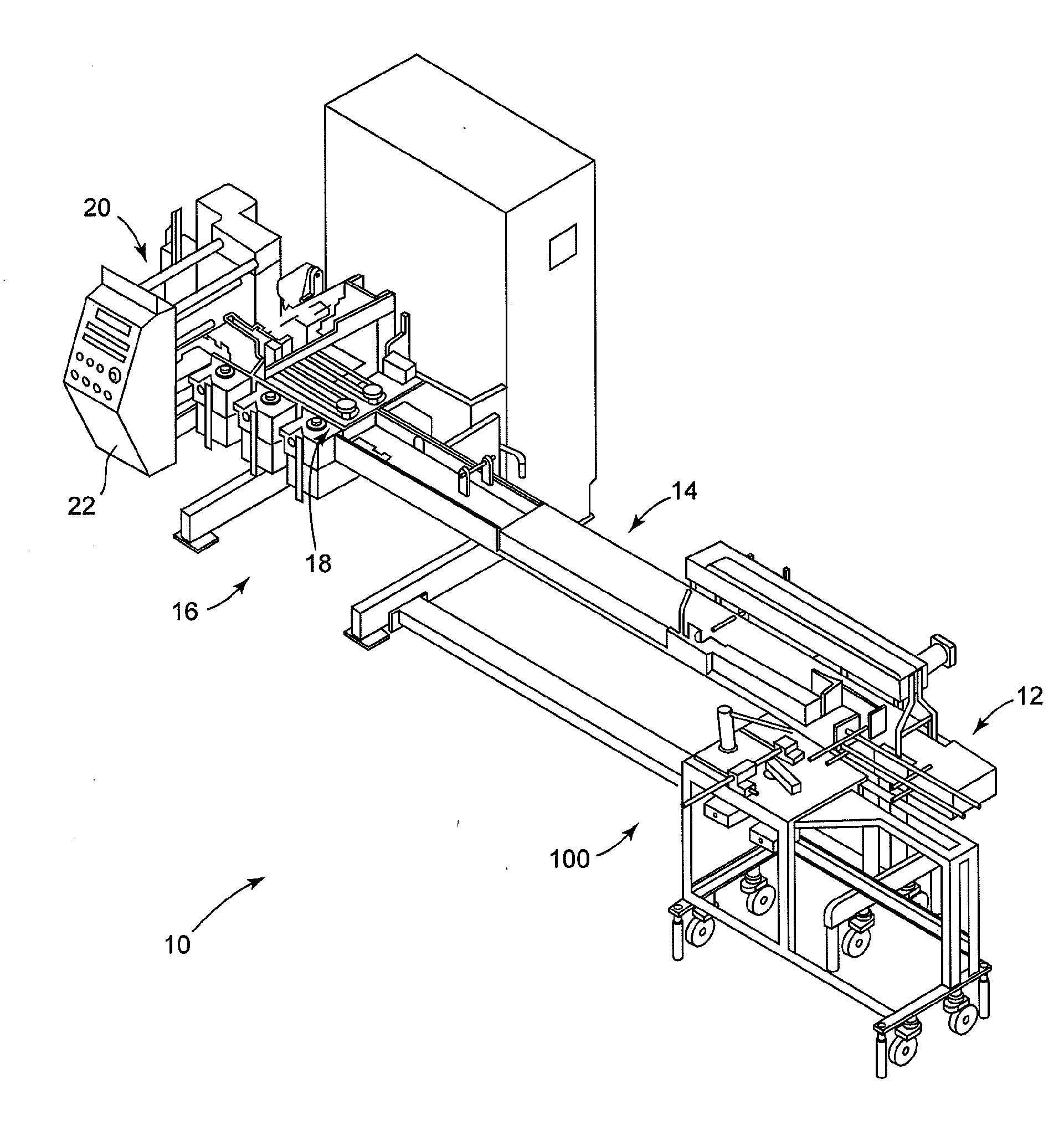

[0024] Generally, the present disclosure relates to a continuous motion inline feeder, such as may be used in biscuit or cracker feeding applications. The continuous motion inline feeder of the present disclosure is adjustable and can accommodate products of various thicknesses. The inline feeder of the present disclosure is also referred to as a "continuous motion" inline feeder because the received product (e.g., biscuit, cracker, or other food / object) continues from an uninte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com