Method for producing coating material

A technology for cladding materials and basic materials, which can be used in adhesive heating bonding methods, manufacturing tools, wood processing appliances, etc., can solve problems such as invisible, and achieve the effect of reducing energy consumption and minimizing the risk of failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

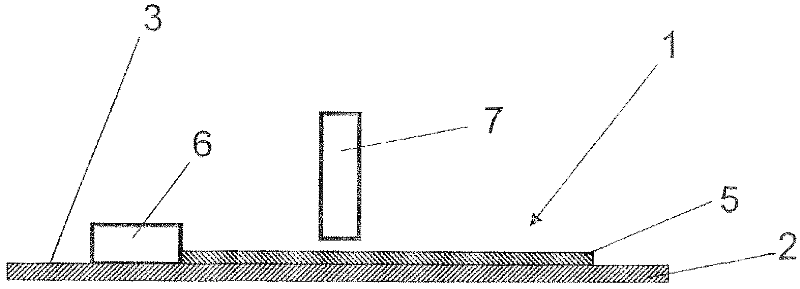

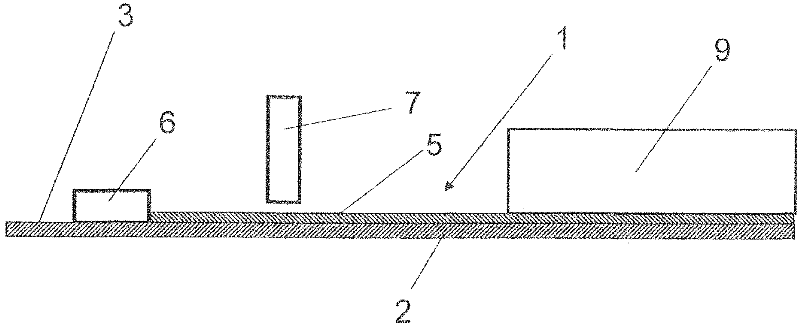

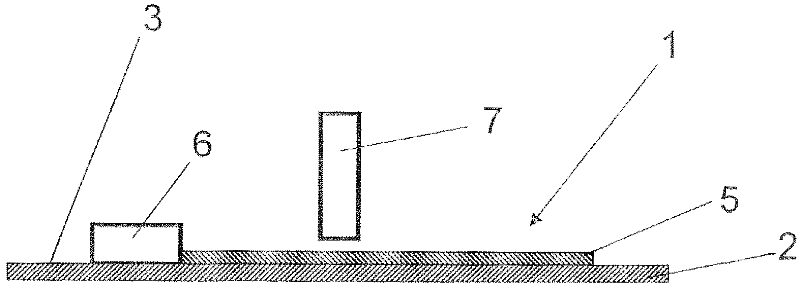

[0017] figure 1 According to a first exemplary embodiment, a schematic cross-sectional view of the process of the method according to the invention for producing the cladding material 1 is shown. According to the exemplary embodiment, a web-shaped base material 2 is provided, which is shown hatched in the figure. The base material 2 is conveyed to a cladding station 6 represented as a rectangle. The surface 3 of the base material 2 , in the figure the upper side, is pretreated by cleaning said surface. Subsequently, the functional layer 5 , which is likewise shown hatched in the figure, is applied to the base material 2 , so that the coating material 1 is formed. By means of the energy source 7 , which is shown as a rectangle in the figure, energy can be introduced into the coating material, in particular into the functional layer 5 , so that said functional layer develops adhesive properties. Here, the energy source 7 is shown for better understanding and is not initially ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com