Plated piece and preparation method thereof

A technology for coating parts and anti-fingerprint, applied in the field of coating parts and their preparation, can solve the problems of failure of anti-fingerprint function, easy to be worn, poor bonding force, etc., so as to improve wear resistance and service life, enhance bonding force, and improve efficiency improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

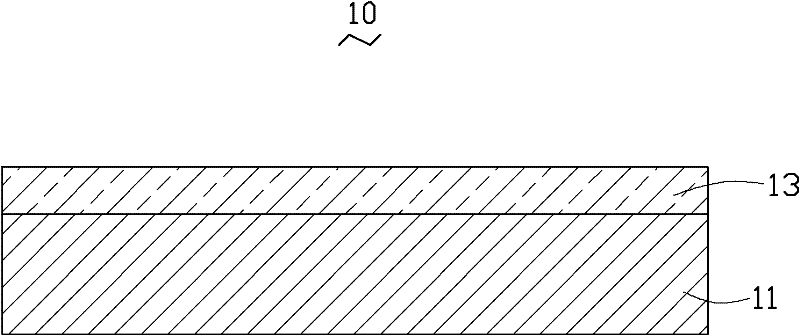

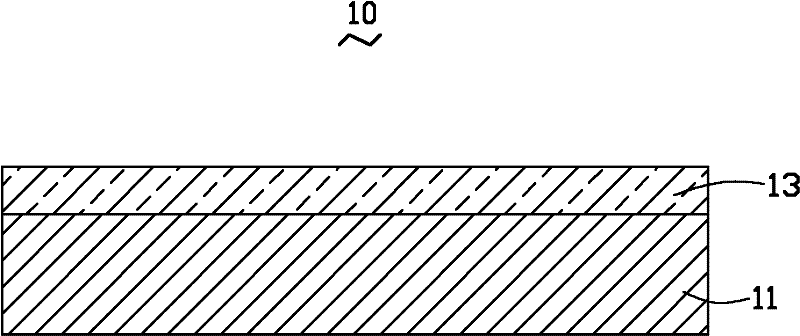

[0018] see figure 1 , a coating member 10 according to a preferred embodiment of the present invention includes a substrate 11 and an anti-fingerprint layer 13 formed on the surface of the substrate 11 .

[0019] The base body 11 can be made of metallic or non-metallic materials. The metal material may include stainless steel, aluminum, aluminum alloy, copper, copper alloy and the like. The non-metallic material can be plastic or ceramic. The base body 11 has a rough surface, which is directly combined with the anti-fingerprint layer 13 . The roughness of the rough surface is 0.05-0.25 micron (μm). The roughness of the rough surface can be formed by sandblasting, laser etching or chemical etching.

[0020] The anti-fingerprint layer 13 is a transparent nanoscale polytetrafluoroethylene layer, which can be made by plasma-assisted deposition coating method. The thickness of the anti-fingerprint layer 13 is below 2 μm, preferably 0.1-0.5 μm. The anti-fingerprint layer 13 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com