Automatic tension balancing rope head device for steel wire rope

An automatic balancing and wire rope technology, applied in the directions of transportation, packaging, elevators, etc., can solve the problems of small force on the wire rope, affecting the comfort of elevator operation, and large maintenance workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

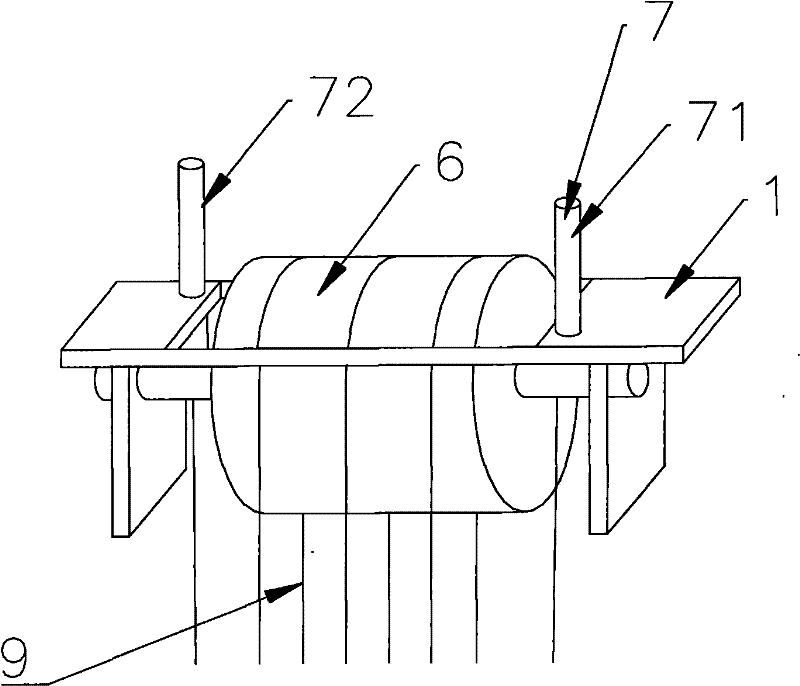

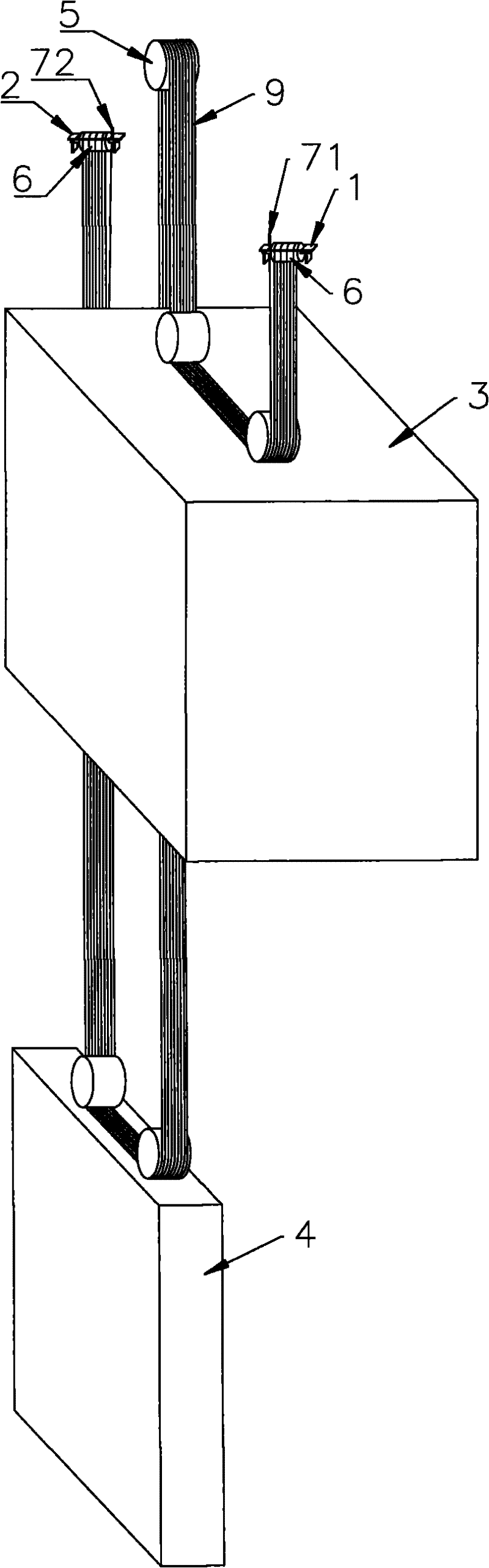

[0012] see figure 1 , 3 The wire rope tension automatic balancing rope head device comprises, wire rope rope head 7 (comprising wire rope starting end 71, wire rope termination end 72), wire rope 9 and pulley 6 for automatic balancing and the pulley seat (comprising car side pulley) that pulley 6 is set Seat 1 and counterweight side pulley seat 2) etc.

[0013] Car side pulley block 1 is fixed on car 3 one sides. The counterweight side pulley seat 2 is fixed on the counterweight 4 side. Wire rope starting end 71 (consistent with traditional rope head) is fixed on an end of car side pulley block 1. The wire rope bypasses the traction sheave 5, the guide wheel rope groove reaches the pulley of the counterweight side pulley seat 2 at the other end and returns, bypasses the traction sheave, the guide wheel rope groove, reaches the pulley on the car side pulley seat 1, and winds After passing the pulley on the pulley seat 1 on the car side, return to the pulley on the pulley se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com