Air supply control system for cut tobacco dryers

A technology of control system and silk drying machine, which is applied in the application, preparation of tobacco, tobacco, etc., can solve the problems of single function, poor drying effect, low degree of intelligence, etc., achieve high degree of intelligence, convenient wiring, and improve drying efficiency. The effect of dry mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

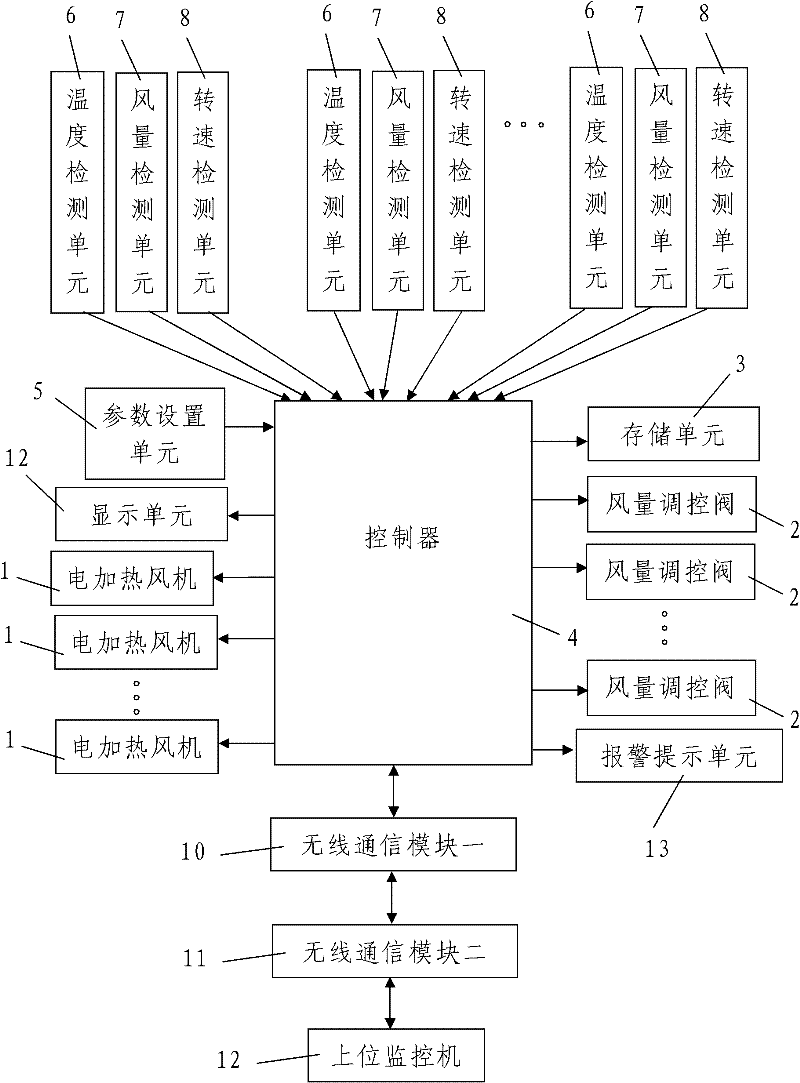

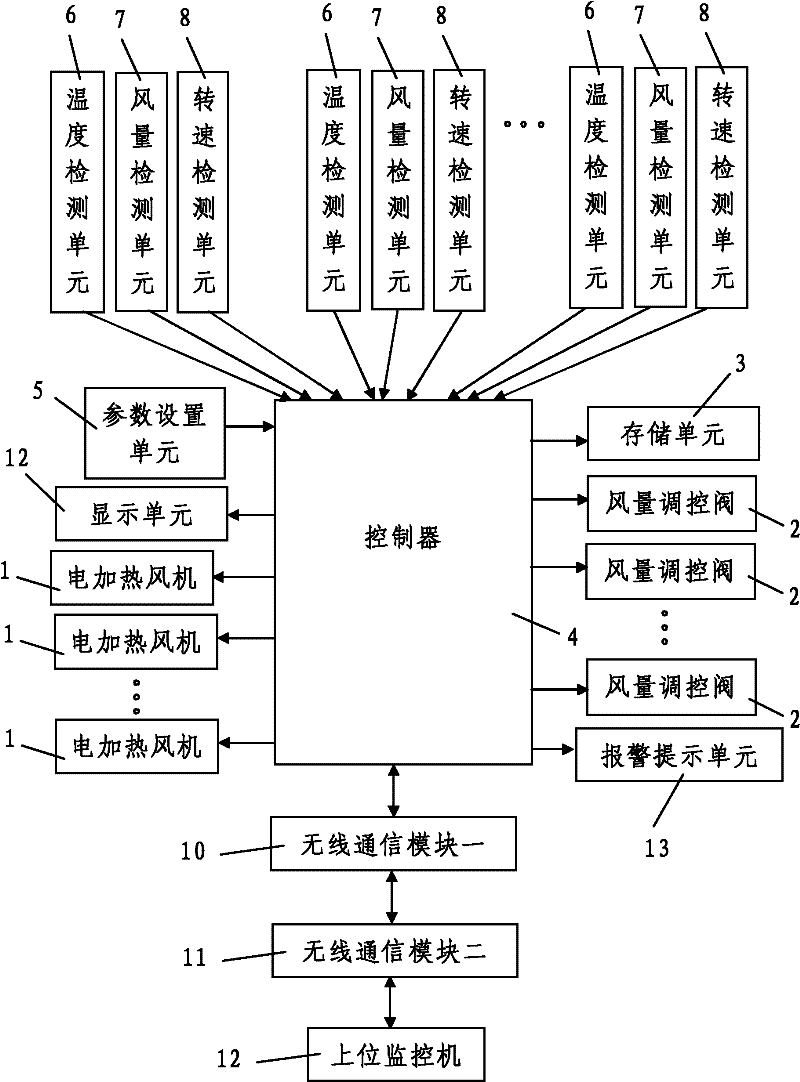

[0027] Such as figure 1 As shown, the present invention includes multiple rows of air supply holes arranged on the inner wall of the controlled wire drying machine from front to back, and multiple electric heaters connected to multiple rows of air supply holes through multiple air supply pipes. Fan 1, a plurality of temperature detection units for real-time detection of the hot air temperature sent by multiple rows of the air supply holes respectively 6, a plurality of air volume detection for real-time detection of the air supply volume of the plurality of air supply pipes respectively Unit 7, a plurality of rotation speed detection units for real-time detection of the rotation speed of a plurality of electric heating fans 1 respectively, a plurality of air volume control valves respectively installed on a plurality of said air supply pipes 2, internal storage of multi-stage standard delivery The storage unit 3 of wind control parameters, the controller 4 and the parameter se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com