Nondestructive test and evaluation method of metal member / material residual life

A metal component and evaluation method technology, which is applied in the direction of testing the ductility of materials, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve the problems of quickly achieving non-destructive evaluation of metal components, failing to quantitatively predict the remaining life of materials, etc., to achieve The effect of fast detection speed, low detection cost and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

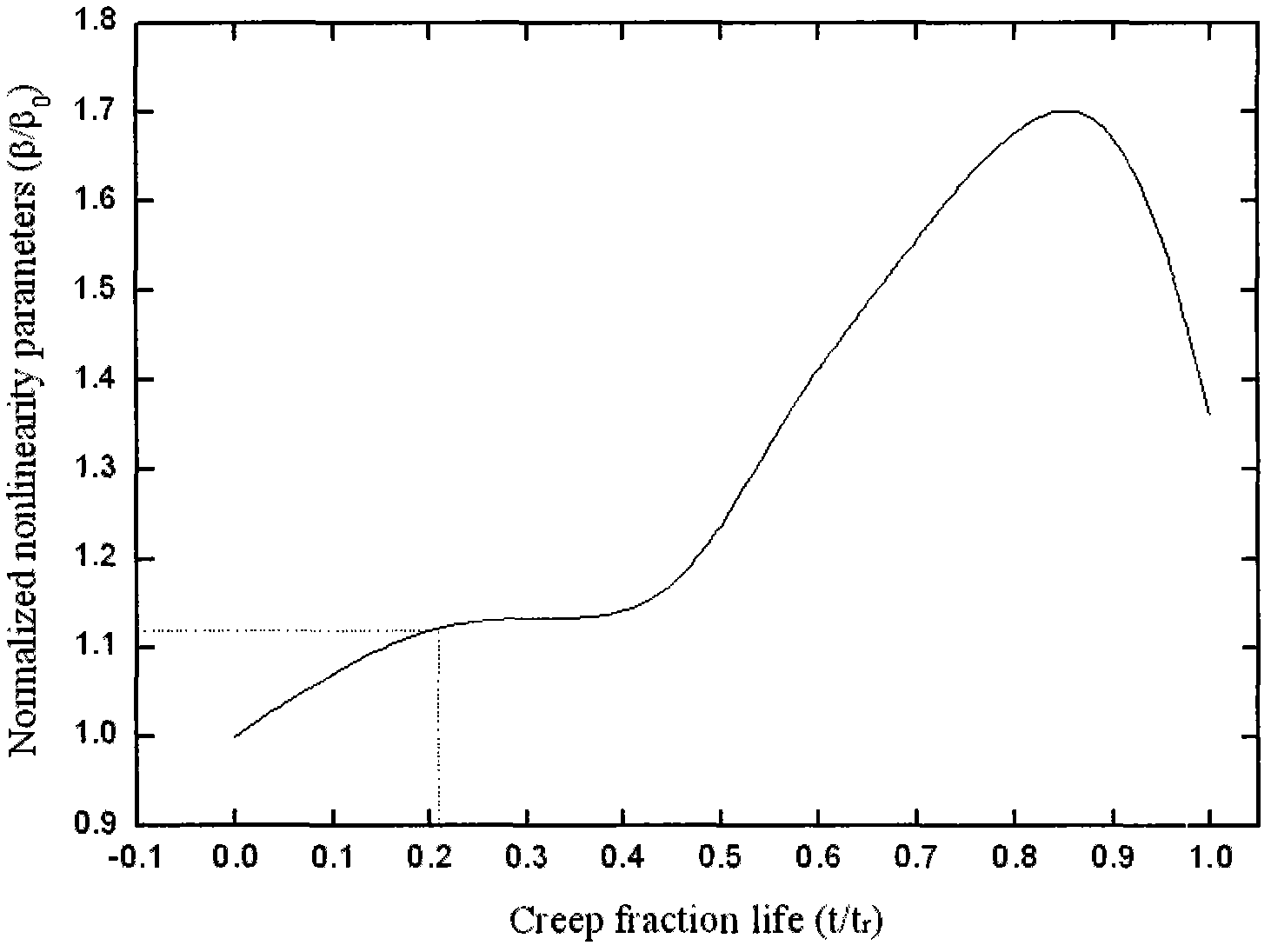

[0029] The technical concept of the present invention is as follows: the performance degradation of metal components / materials after fatigue loading, creep loading and other damages is closely related to the nonlinear effect of ultrasonic propagation in materials, that is, material performance degradation is always accompanied by some form of The nonlinear mechanical behavior of the material causes the generation of nonlinear harmonics in ultrasonic propagation. Dislocation String Model in metallic materials [Hikata A, Chick B, Elbaum C. Dislocation contribution to the second harmonic generation of ultrasonic waves. J.Appl.Phys.1965, 36(1): 229-236 ] think that the dislocation-to-dislocation interaction in the crystal or the internal point defects will form pinning points on the dislocation line. On these pinning points, the dislocation line is not easy to move, but in the Between two adjacent pinning points, under the action of stress, the dislocation line will produce a forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com