Processing method of medium-low temperature coal tar

A technology of low temperature coal tar and processing method, which is applied in the field of processing medium and low temperature coal tar by hydrorefining method, can solve the problems such as the inability to realize long-term operation of a hydrogenation unit, the problem of olefin coking, and the impact on the economy of the processing unit, and the like. Achieve the effect of improving the utilization rate and the economy of processing equipment, realizing long-term operation, and solving the problem of coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

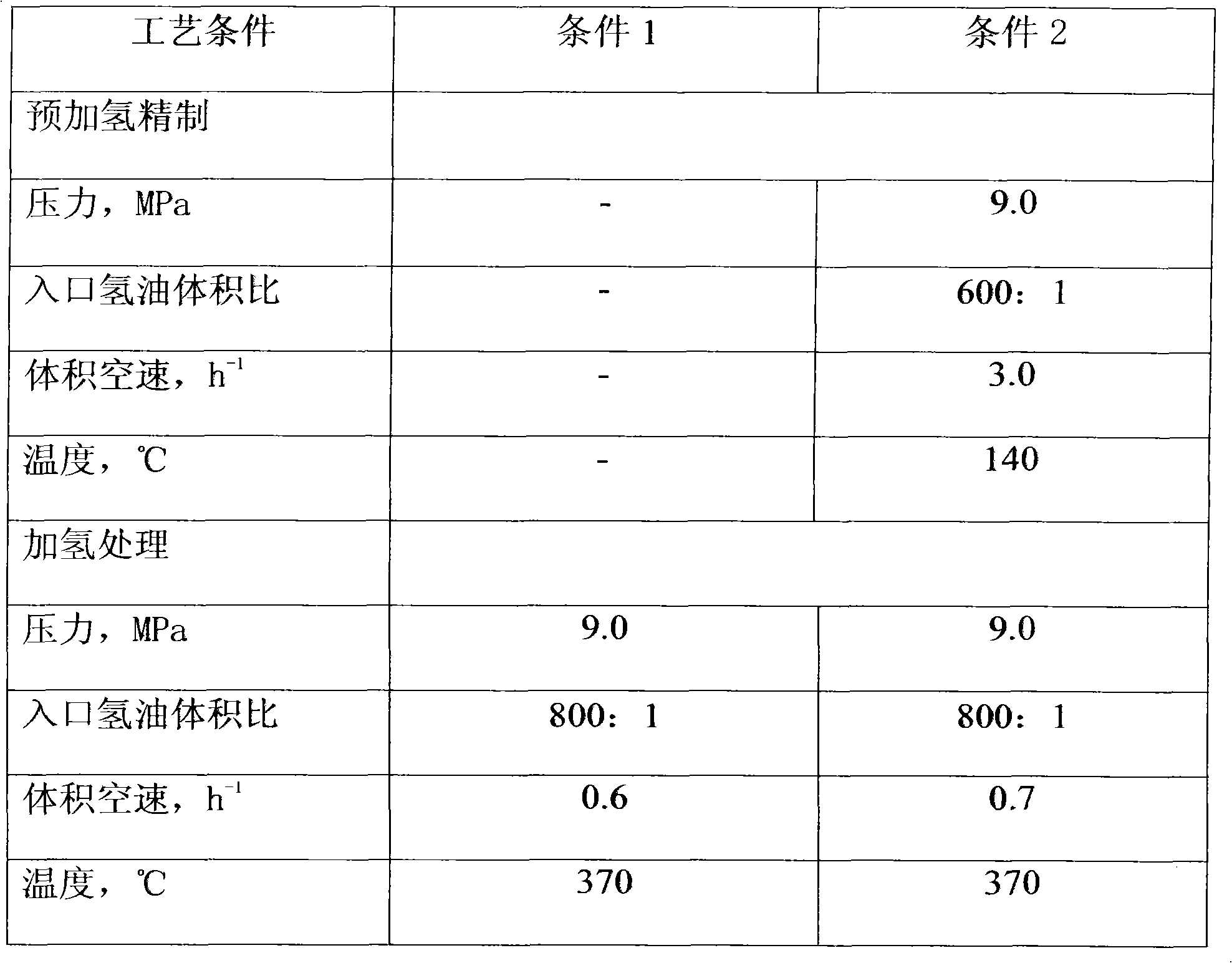

Embodiment 1

[0028] The properties of the medium and low temperature coal tar used in the Lurgi method are shown in Table 1. The pre-hydrofining catalyst can choose the FHRS-1 catalyst developed and produced by Fushun Petrochemical Research Institute, the hydrogenation protection catalyst can choose the FZC-103 catalyst developed and produced by Fushun Petrochemical Research Institute, and the conventional hydrofining catalyst uses Fushun Petrochemical Research Institute The properties of the 3936 hydrotreating catalyst developed and produced are shown in Table 2.

[0029] Table 1 Raw Oil Properties

[0030] Raw oil name

[0031] Olefin

[0032] The main composition and properties of the catalyst used in table 2

[0033] catalyst

[0034] The acid-base extraction was carried out with the low-temperature coal tar light distillate in the Lurgi method as a raw material, and the alkali used was an alkali solution with a weight concentration of 8% sodium hydroxide...

Embodiment 2

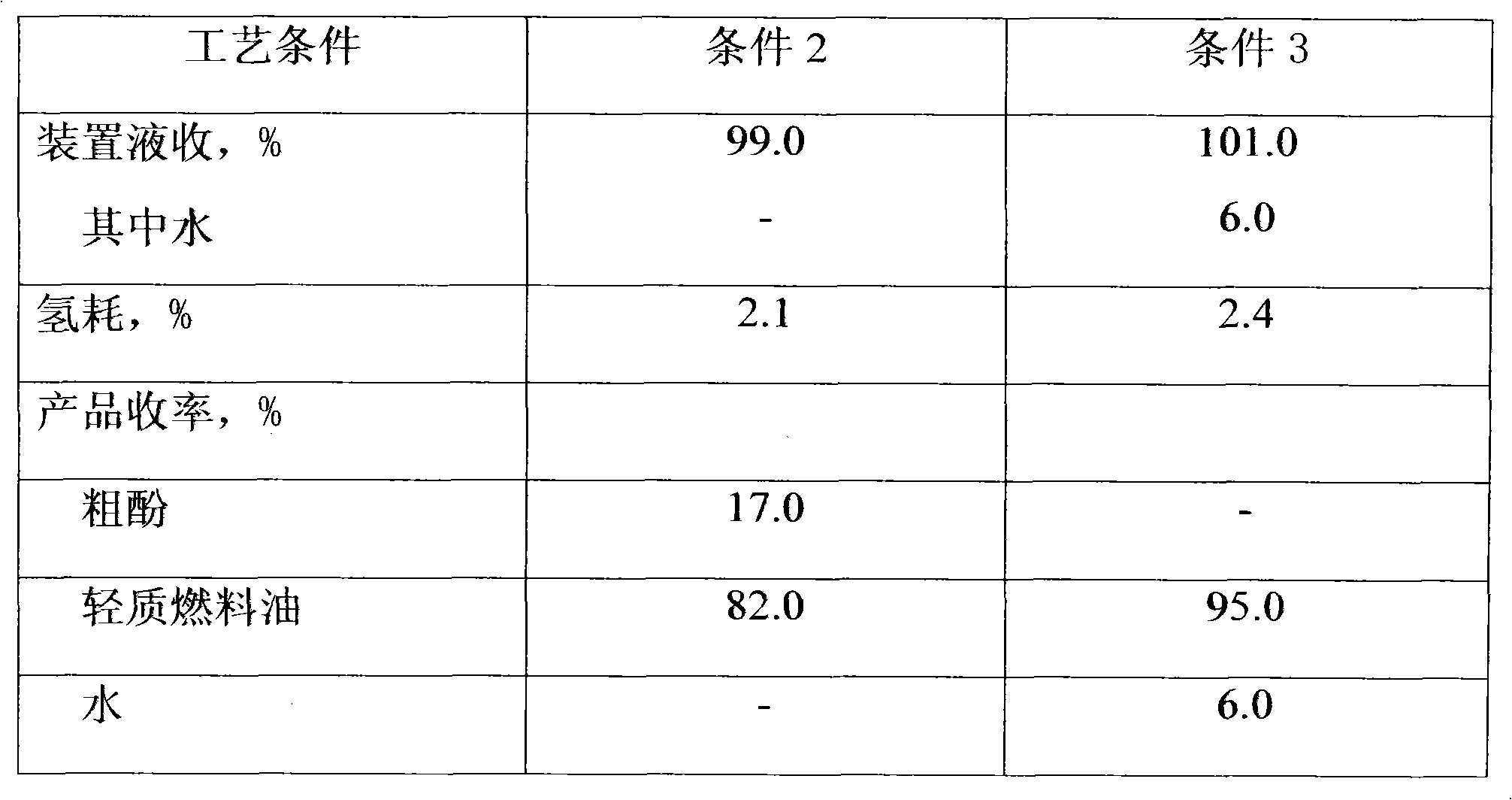

[0044] Catalyst used, raw material and hydrogenation process condition are identical with embodiment 1, and condition 2 is the same as condition 2 in embodiment 1, and difference is that condition 3 directly carries out pre-hydrogenation refining / Hydrofining, that is, directly enter the hydrogenation reactor without dephenolization treatment. The test results are shown in Table 5.

[0045] The light fraction of medium and low temperature coal tar directly enters the hydrogenation reactor without dephenolization treatment, which increases the processing load of the hydrogenation unit, and the phenolic compounds in the raw material are partially converted into water and blended with fuel oil whose price is lower than that of crude phenolic products Components, while also increasing the hydrogen consumption; while the method of first dephenolization and then hydrogenation will significantly improve the economy.

[0046] Table 5 embodiment 2 test result

[0047]

Embodiment 3

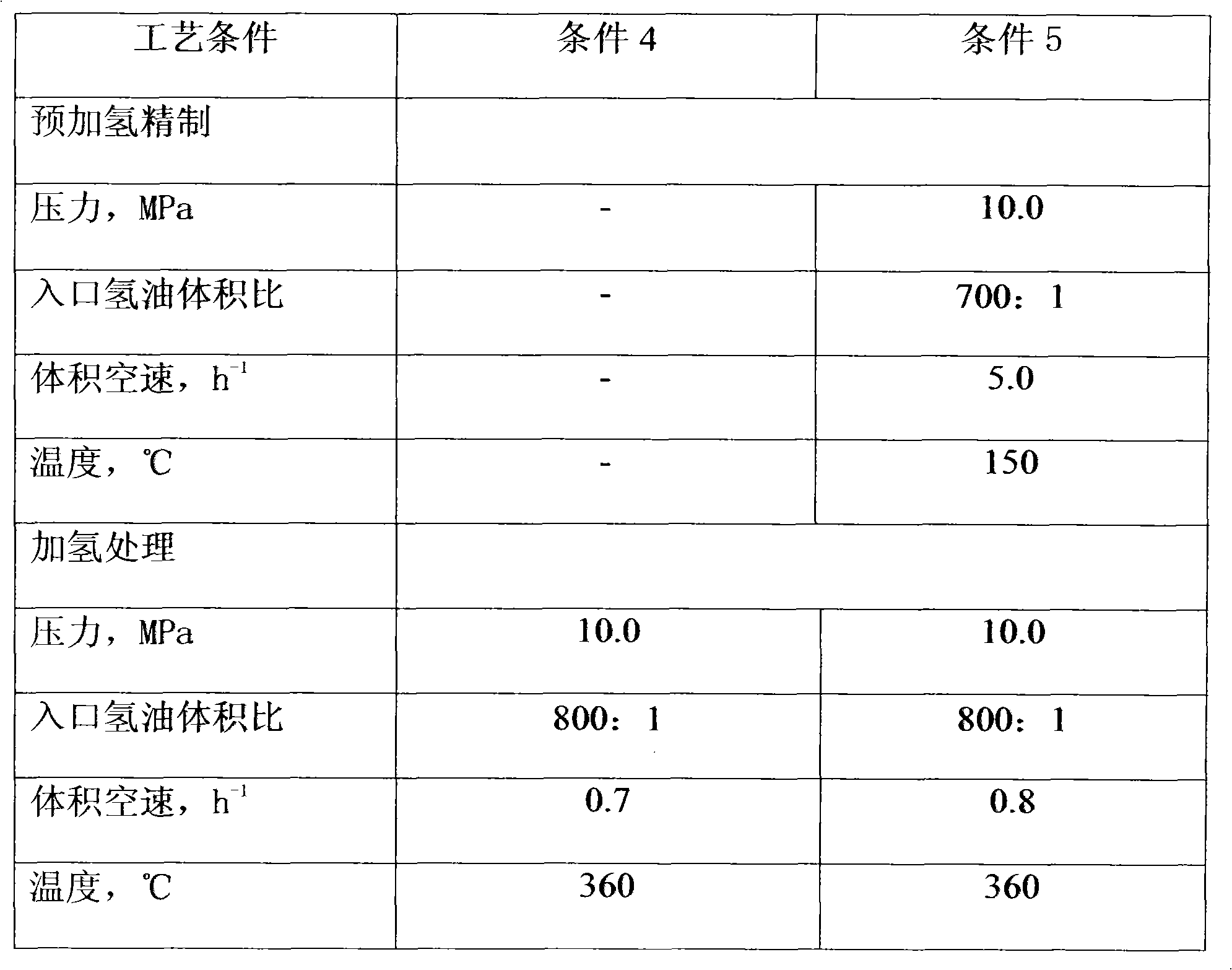

[0049] The catalyst and raw materials used are the same as those in Example 1 and Condition 2, and a 5000-hour stability comparison test is carried out. The process conditions are shown in Table 6, and the test results are shown in Table 7.

[0050] Condition 4: No pre-hydrofining process is used, and the dephenolized oil directly enters the hydrotreating reactor. After 3000 hours, the pressure drop of the hydrotreating reactor has reached 0.3 MPa, which is close to the maximum value allowed by the industrial hydrogenation unit. Shutdown treatment is required, and most of the area above the heat exchanger and the protective agent bed of the hydrotreating reactor It is covered with a thick layer of carbon deposits.

[0051] Condition 5: Pre-hydrofinishing is used and then hydrofinishing reaction is carried out. The hydrogenation unit has been in operation for 5,000 hours, and the pressure drop of the hydroprocessing reactor has been significantly reduced to 0.10MPa, which can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com