Longitudinal beam device for beam-adjustable vehicle

An adjustable and longitudinal beam technology, which is applied to vehicle components, transportation and packaging, and substructure, etc., can solve problems such as engine and gearbox installation that cannot be adjusted, engines and gearboxes that are not properly positioned, and controllability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

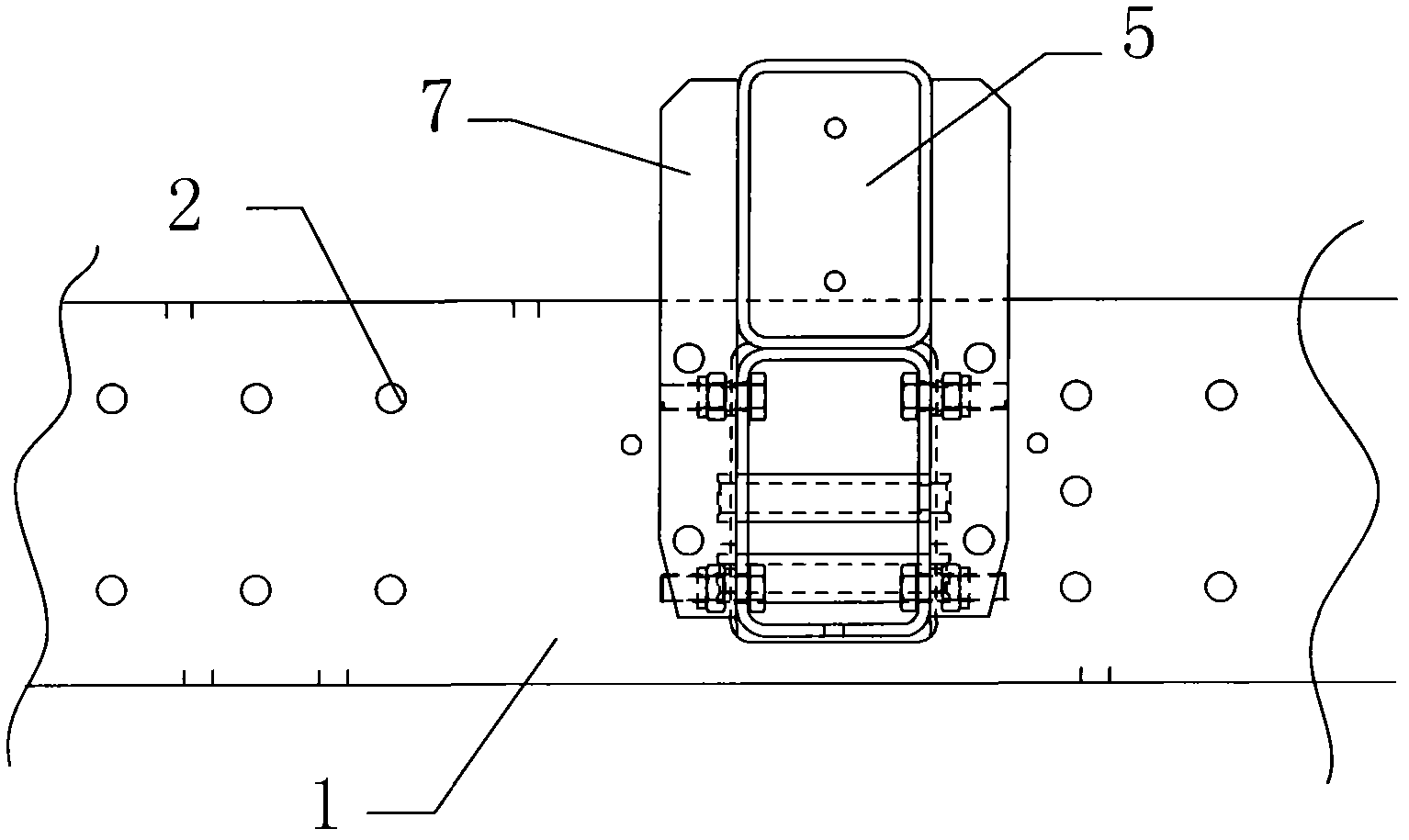

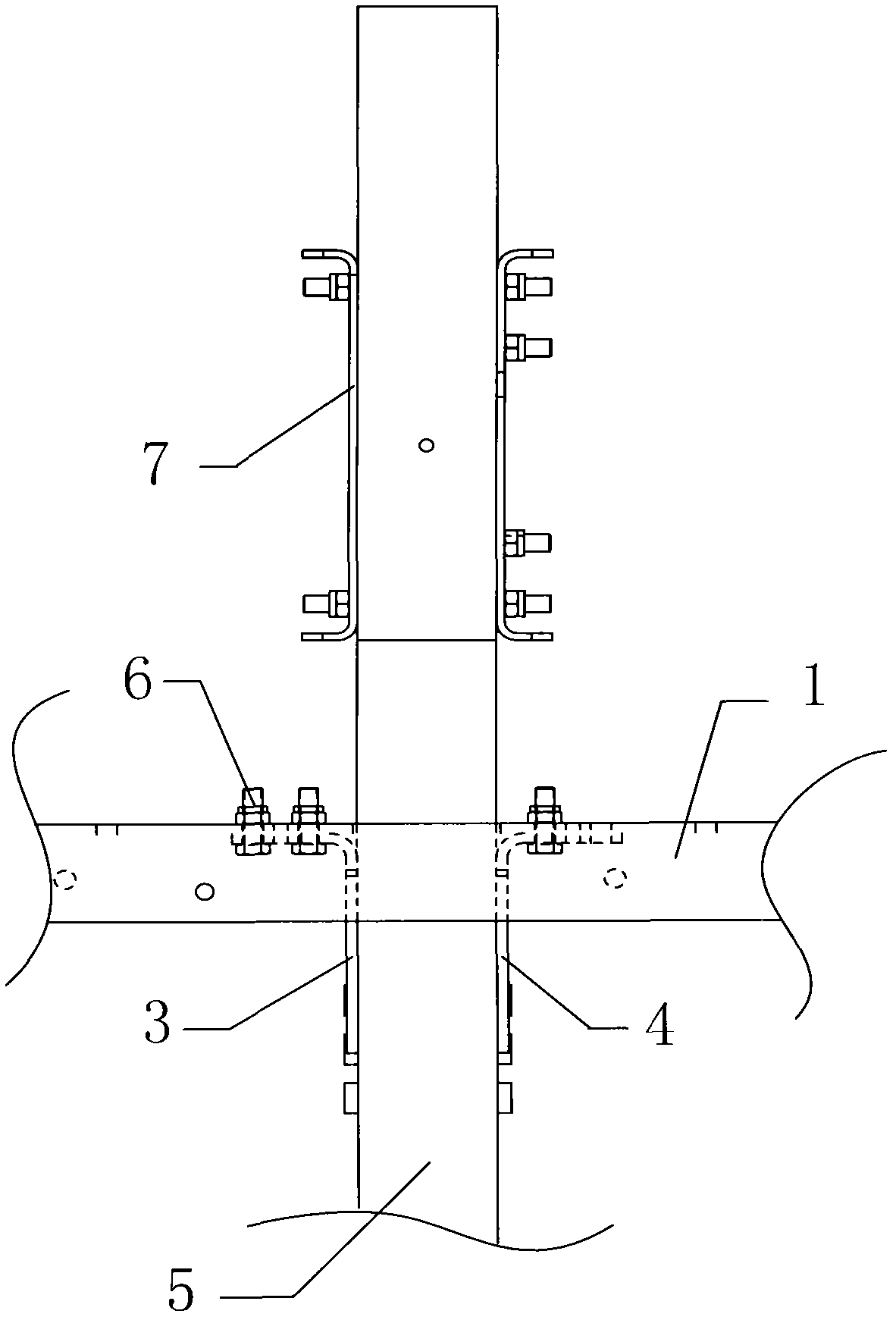

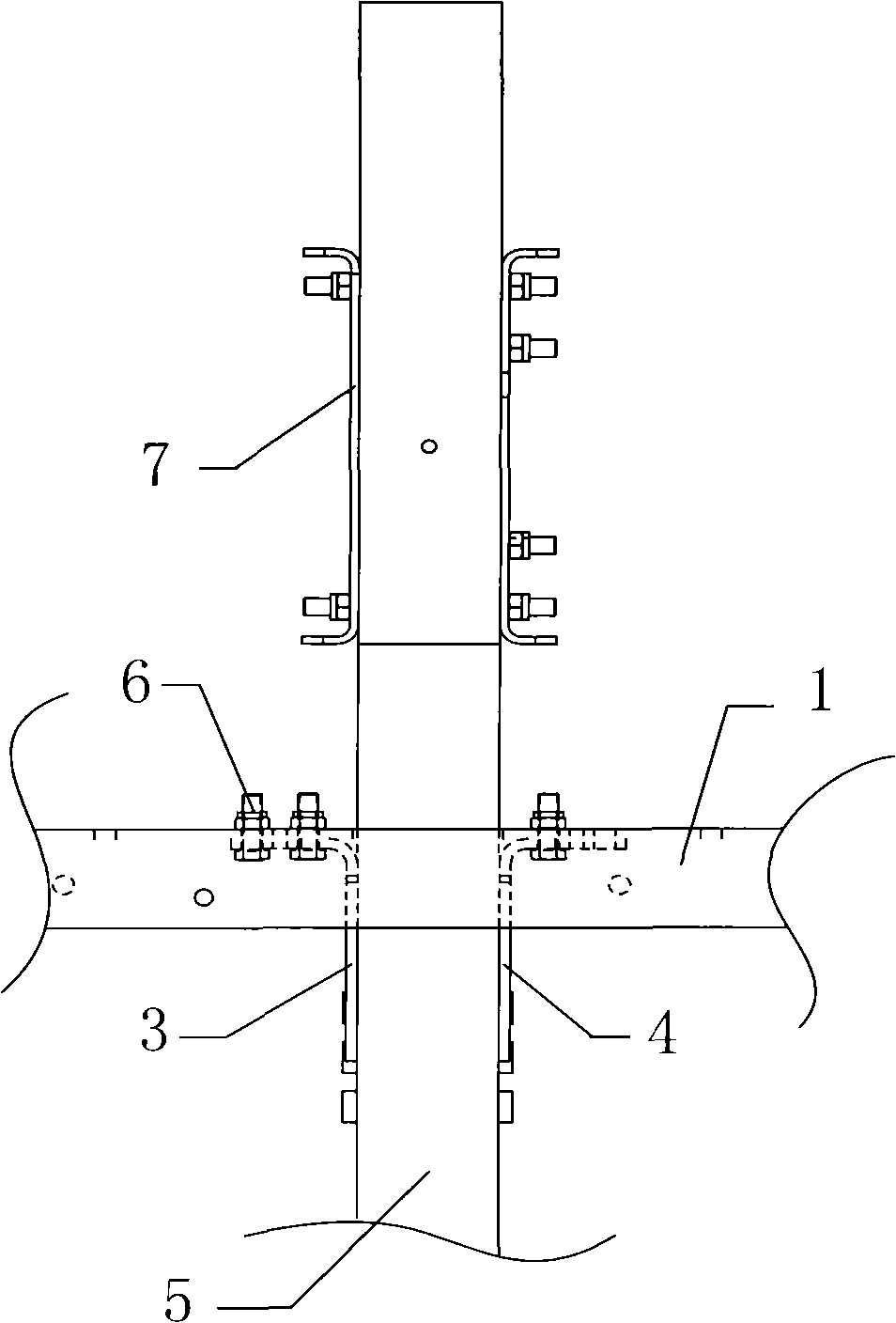

[0020] Such as figure 1 , figure 2 As shown, a vehicle longitudinal beam device with an adjustable crossbeam includes a longitudinal beam frame body 1, and its difference is that the installation through holes 2 are distributed on the longitudinal beam frame body 1 adopted by the present invention, and in these installation through holes An auxiliary fixing component is connected to the position corresponding to the hole 2. At the same time, the beam 5 is clamped on the auxiliary fixing assembly.

[0021] In view of a preferred embodiment of the present invention, in order to effectively fix the crossbeam 5, it is ensured that it is closely combined with the longitudinal beam frame 1 and that no displacement deviation occurs during the running of the vehicle. Specifically, the auxiliary fixing assembly adopted in the present invention includes a main right-angle main fin 3 and a secondary right-angle aileron 4 . At the same time, the first working surfaces of the main righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com