Truck tire

A tire and bead technology, applied to tire parts, bead, transportation and packaging, etc., can solve the problems of insufficient improvement of tire durability, and achieve the effects of restraining wear, restraining cord end loosening and restraining friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

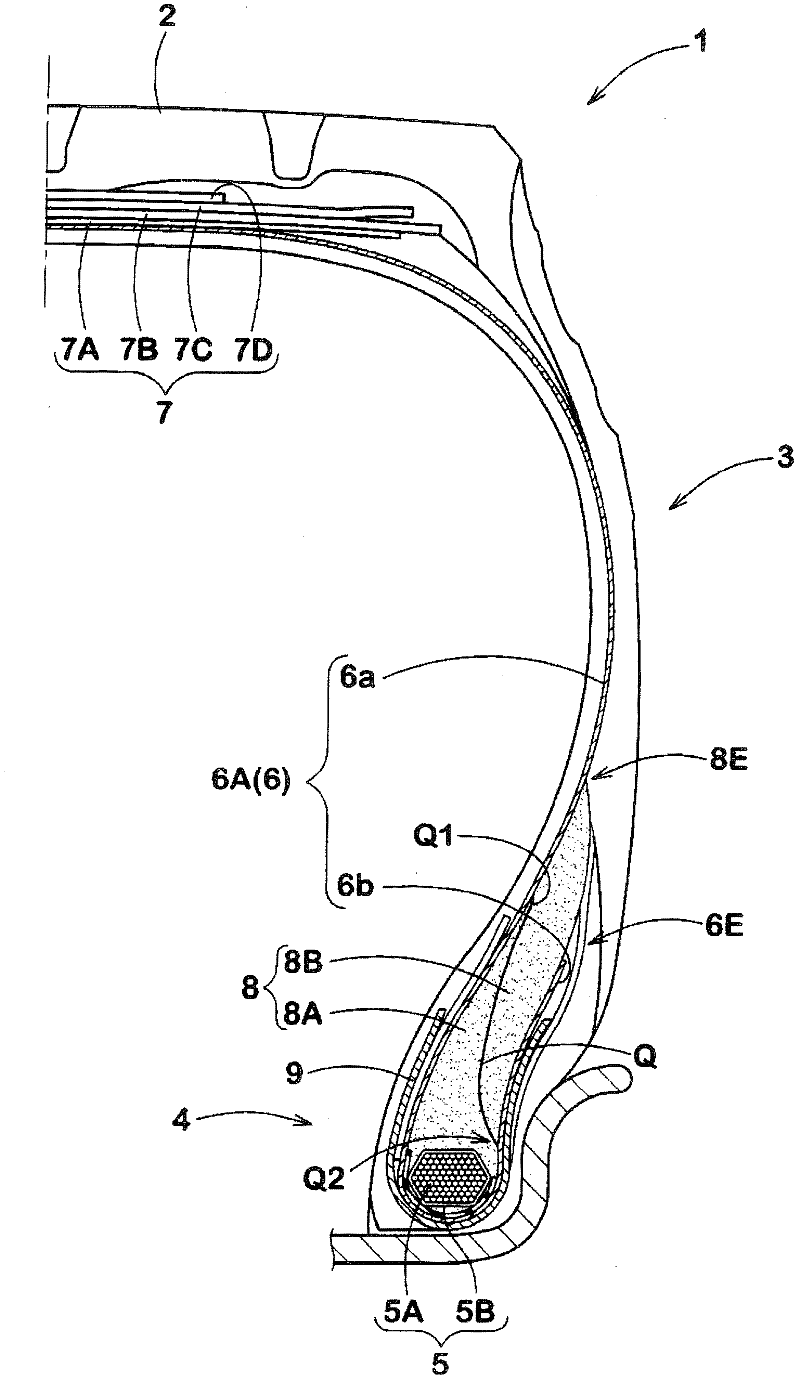

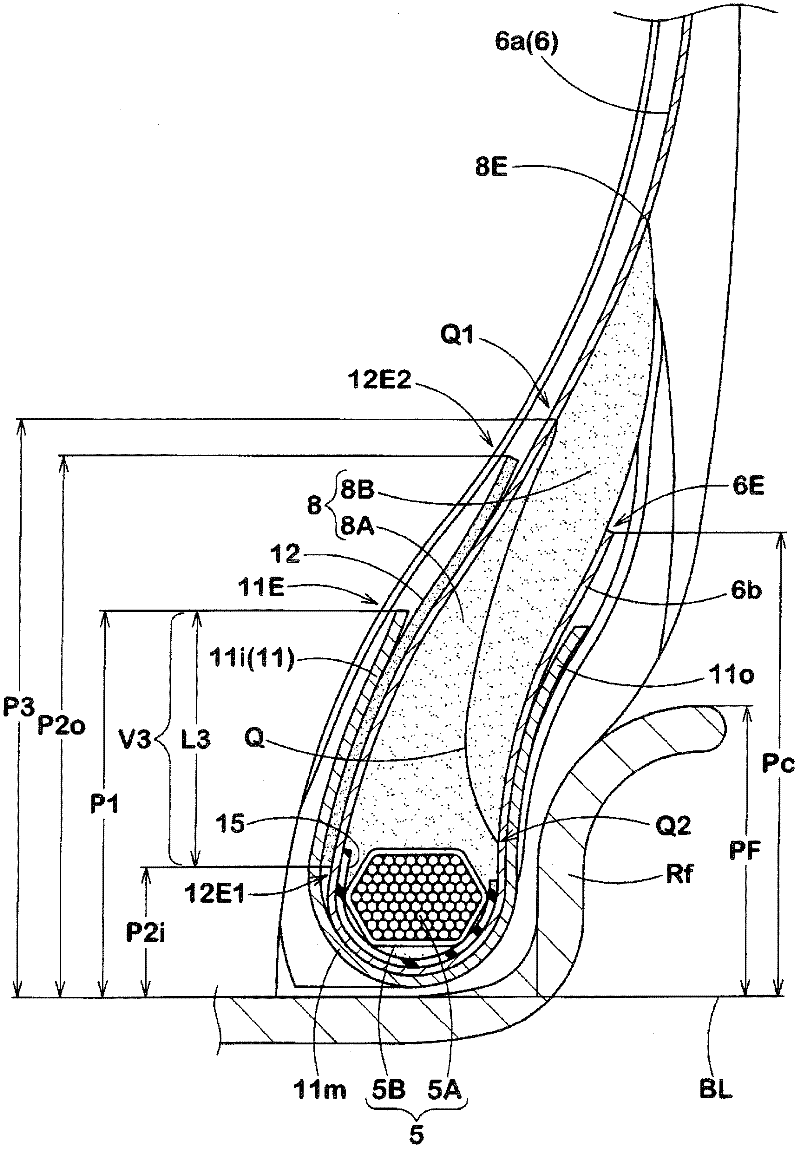

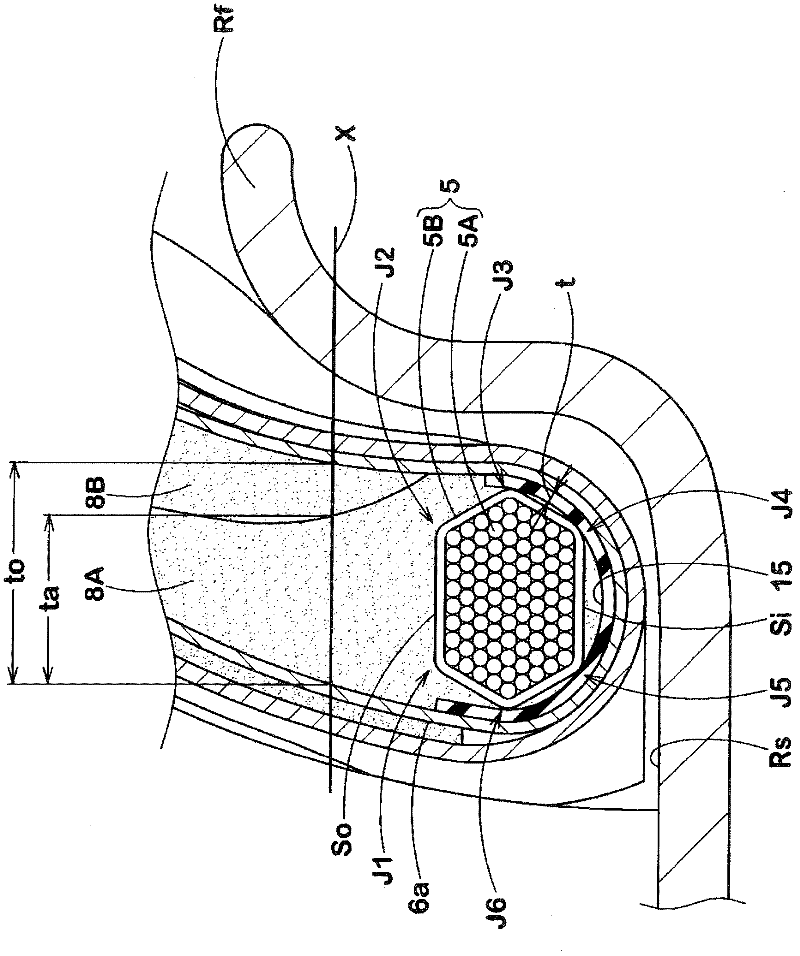

[0065] Based on the specifications in Table 1, the trial production has figure 1 The basic construction of the truck tire (size 11.00R20), and the wear resistance and general bead durability performance of each test tire were tested. Except for the specifications described in Table 1, all are the same specifications.

[0066]

[0067] ·High elastic apex part----complex elastic modulus E*1=50Mpa,

[0068] ·Low elastic apex part----complex elastic modulus E*2=4.0Mpa,

[0069] The radial height of the high elastic apex from the bead baseline BL--90mm,

[0070] The radial height of the low elastic apex from the bead baseline BL--120mm,

[0071]

[0072] ·Cord---3+8+13 / 0.23

[0073] ·The number of embedded cords----26 / 5cm (measured under the bead core)

[0074] ·The radial height Pc of the outer end of the cord return part---72mm

[0075]

[0076] ·Bead wire---φ1.55mm (after glueing )

[0077] ·Construction---8+9+10+11+12+11+10+9+8

[0078]

[0079] ·Cord---3+8 / 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com