Production of fatty acid esters

A technology of fatty acid ester and fatty acid ethyl ester, applied in the field of fatty acid ester, can solve problems such as oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

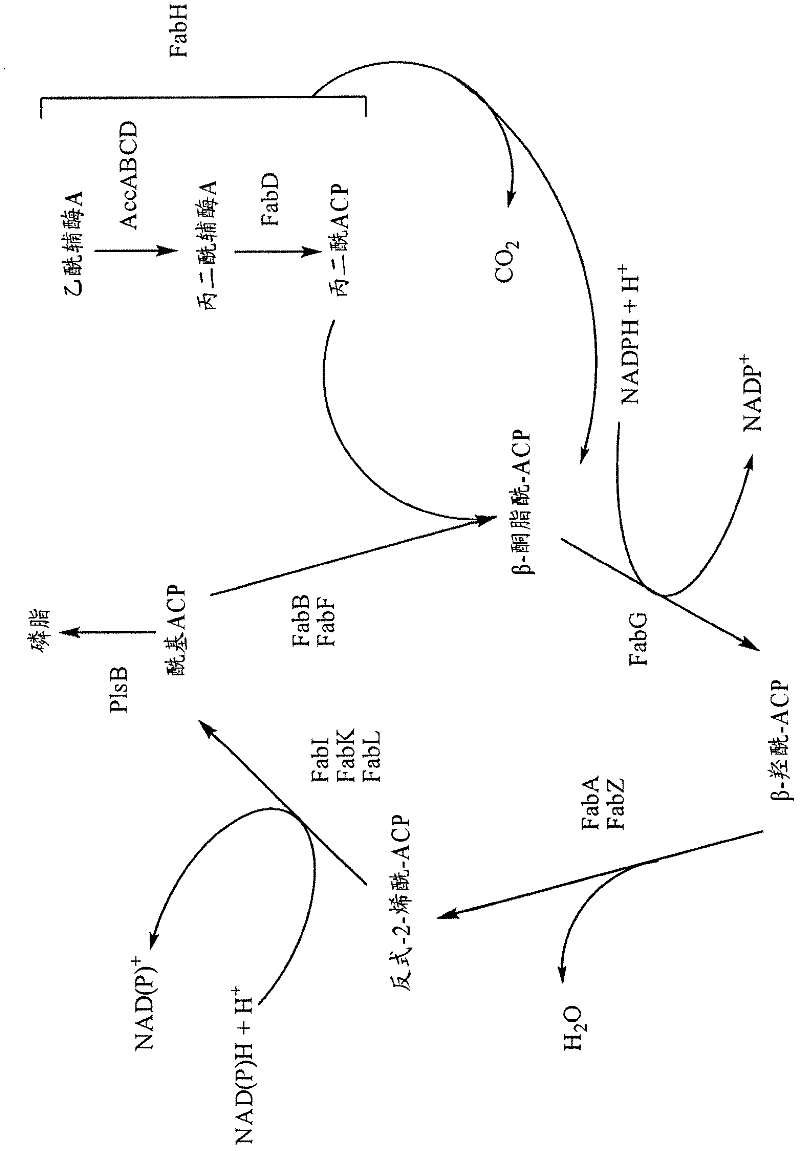

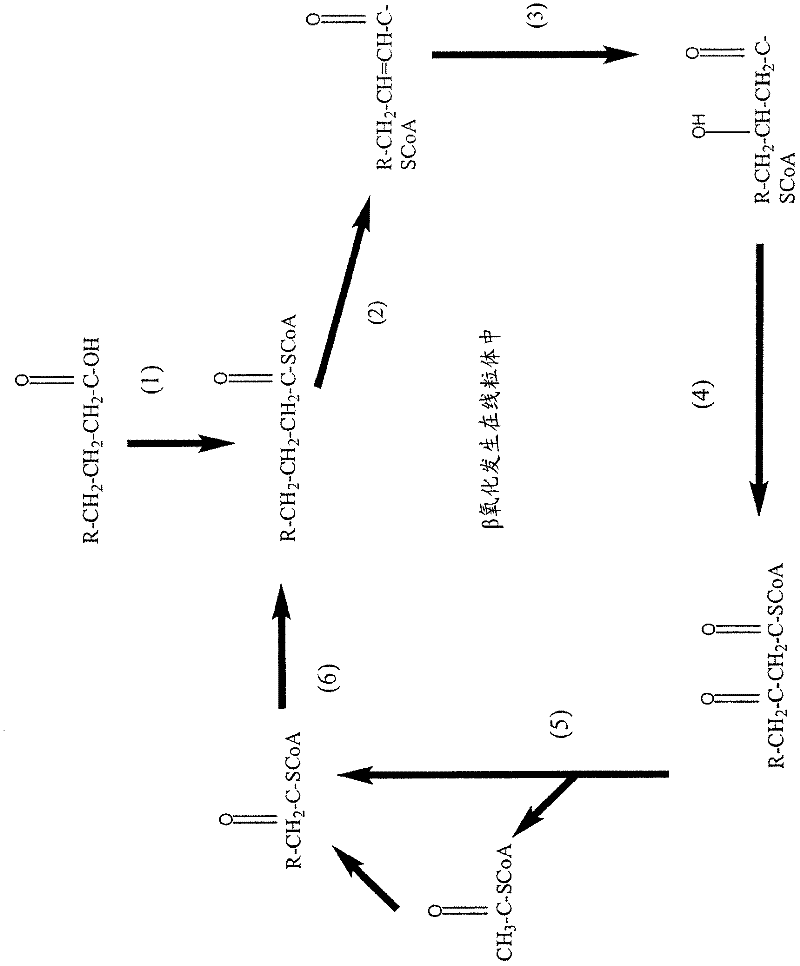

Method used

Image

Examples

Embodiment 1

[0358] Example 1. FAEE production without exogenous ethanol, multiple feeds of methanol

[0359] First, a modified Escherichia coli Δ4 strain (MG1655) carrying a plasmid containing 'tesA, fadD and atfA1 was constructed. Δfad E · Δfab R · Δpox B · ΔldhA).

[0360] 1. Construction of Δ4 strain:

[0361] Escherichia coli MG1655 (an Escherichia coli K strain) was introduced using the lambda red system (also known as red-driven integration) described in Datsenko et al., Proc. ), the fadE gene of ) was deleted, wherein the following changes were made to the system.

[0362] Use two primers to generate deletions:

[0363] Del-fad E-F

[0364] 5'-AAAAACAGCAACAATGTGAGCTTTGTTGTAATTATATTGTAAACATATTGATTCCGGGGATCCGTCGACC (SEQ ID NO: 1)

[0365] Del-fad E-R

[0366] 5'-AAACGGAGCCTTTCGGCTCCGTTATTCATTTACGCGGCTTCAACTTTCCTGTAGGCTGGAGCTGCTTC (SEQ ID...

Embodiment 2

[0922] Example 2. Production of FAEE in the absence of exogenous ethanol, with a single methanol feed

[0923] A modified E. coli Δ4 strain carrying a plasmid containing 'tesA, fadD and atfA1 (as described in Example 1) was grown in a fermentor under aerobic conditions favoring growth and fatty acid methyl ester production. Initially, cells were grown with excess glucose and excess oxygen. No accumulation of ethanol was observed. After induction, the culture is maintained with a glucose feed lower than that consumed so that glucose does not accumulate. The glucose feed rate was faster than in Example 1. Methanol was added only once at a concentration of about 10 g / L. In the early stages of fermentation, the results were similar to Example 1, 78% FAME and 22% FAEE. However, late in the run, glucose consumption decreased, glucose accumulated in the fermenter, and methanol concentration dropped to about 5 g / L. At this point, the culture had almost stopped producing FAMEs and...

Embodiment 3

[0924] Example 3. Production of FAEE in the absence of supply of exogenous alcohol

[0925] Escherichia coli strain ID1 (MG1655ΔfadE constructed according to Example 1, which has an operon containing the genes 'tesA, fadD and atfA1 integrated in the chromosome and controlled by the Trc promoter) under conditions favorable for growth and free fatty acid production grown in fermenters.

[0926] Initially, the cells were grown with an excess of glucose (5 g / L) and given an exponential glucose and mineral feed to the cells, allowing the cells to -1 growth at a rate of ; following this feeding, a fixed feeding regimen was given. Throughout the run, maintain the cultures fully aerobic. No exogenous alcohol was added to the medium. A small amount of ethanol was produced and a large amount of free fatty acids was produced. The engineered fatty acid pathway includes ester synthase, the main enzyme responsible for the production of esters in the presence of added alcohol. In this cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com