OLED (Organic Light Emitting Diode) reticle, manufacturing method thereof and reflecting type sighting telescope

A manufacturing method and reticle technology, applied in telescopes, semiconductor/solid-state device manufacturing, instruments, etc., can solve the problems of high cost, difficulty in disassembly and assembly, space occupied by reticle and lighting system, etc., and achieve low cost, Great flexibility and space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

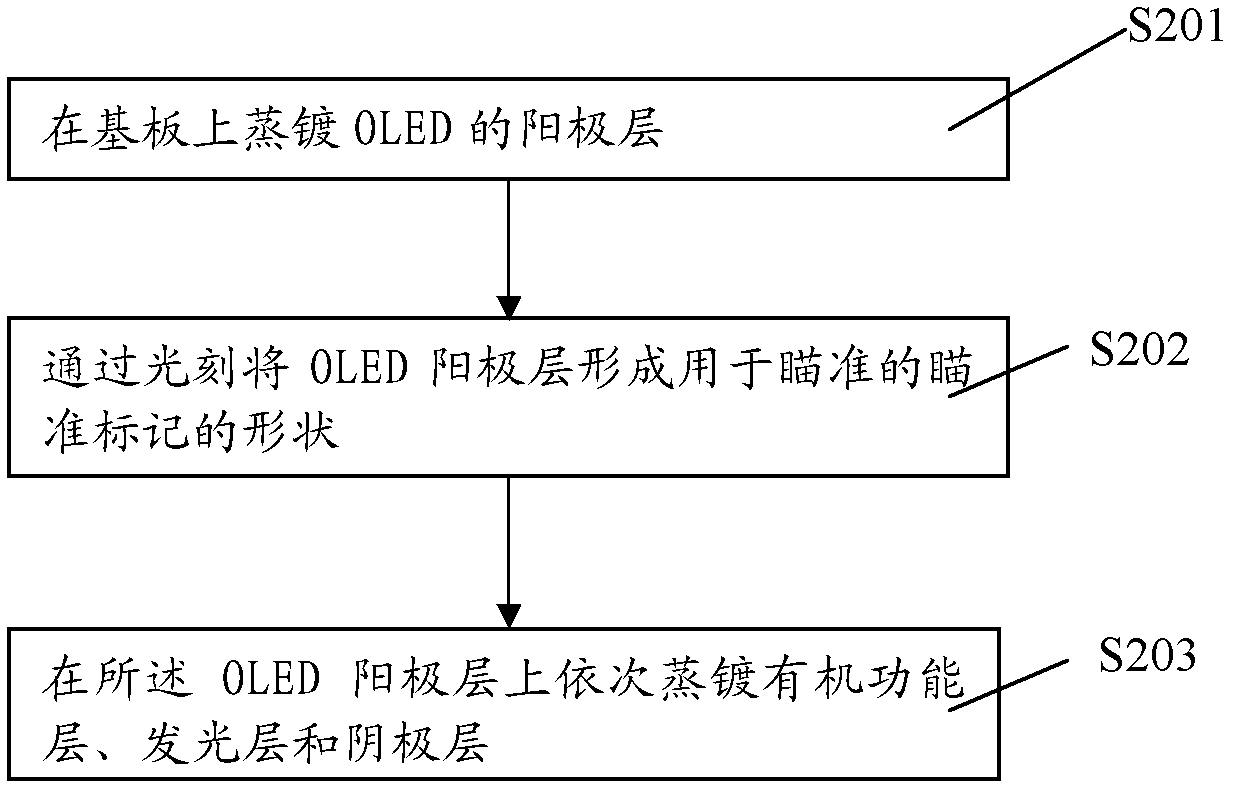

[0039] The OLED reticle of this embodiment of the present invention is made by the following method:

[0040] First, a layer of ITO conductive film is evaporated on the OLED substrate as the OLED anode layer;

[0041] Next, the ITO conductive film was formed into the shape of the aiming mark by photolithography, thereby forming the anode layer of the OLED in the shape of the aiming mark. Such as Figure 4 As shown, it gives the shape of the pattern of the aiming mark photoetched on the anode layer, wherein the circle is the shape of the lens (such as the shape of the lens of the reflex sight), and the shape of the pattern of the aiming mark includes the the graduated lines 11 and 12, the arrowed line 14, and the curve and the graduated line 13 in the area between the graduated line 11 and the arrowed line 14 on the radius of the circle;

[0042] Next, an organic functional layer, a light-emitting layer and a cathode layer are sequentially vapor-deposited on the OLED anode laye...

Embodiment 2

[0045] In this embodiment, the OLED anode layer of the OLED reticle is photoetched into the shape of a cross-shaped aiming mark, such as Figure 5 shown. Others are the same as in Example 1.

Embodiment 3

[0047] In this embodiment, the OLED anode layer of the OLED reticle is photoetched in the shape of an aiming mark with a cross and a small circular ring in the center of the cross, as Figure 6 shown. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com