Automatic temperature control system for plastic welder

A technology of plastic welding and automatic temperature control, which is applied in the direction of control/regulation system, temperature control, non-electric variable control, etc., can solve the problems of poor welding quality, thermal deformation, etc., and achieve convenient parameter adjustment, quality assurance, and intuitive display effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

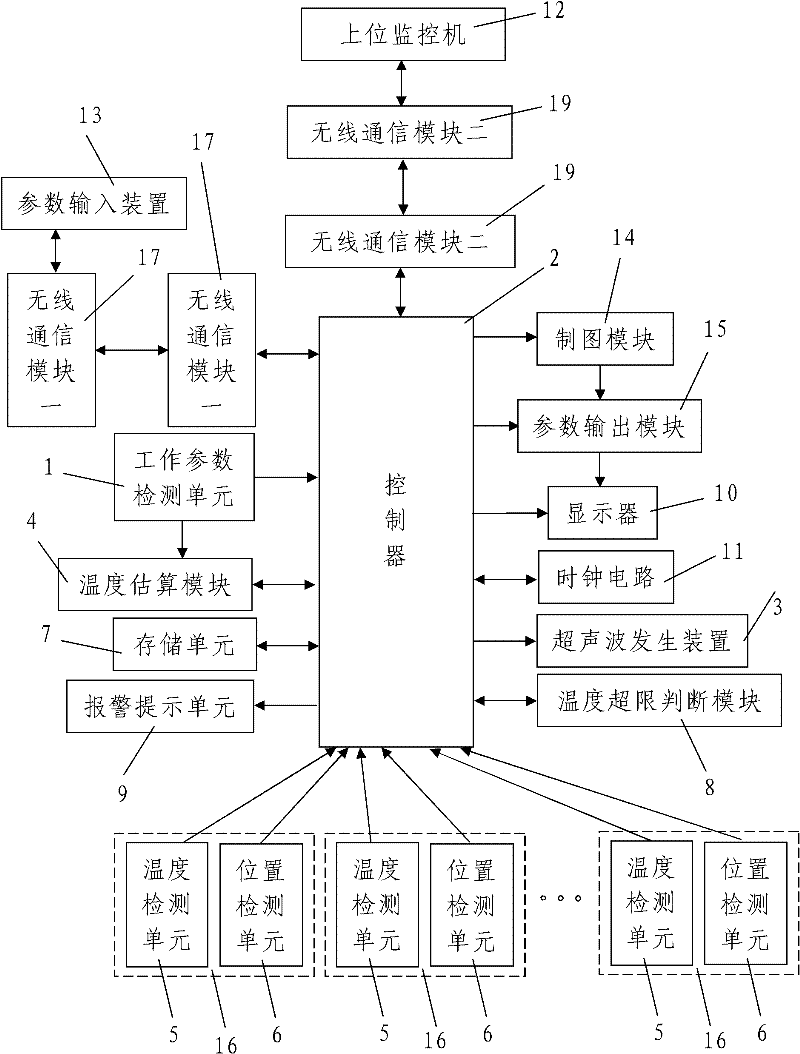

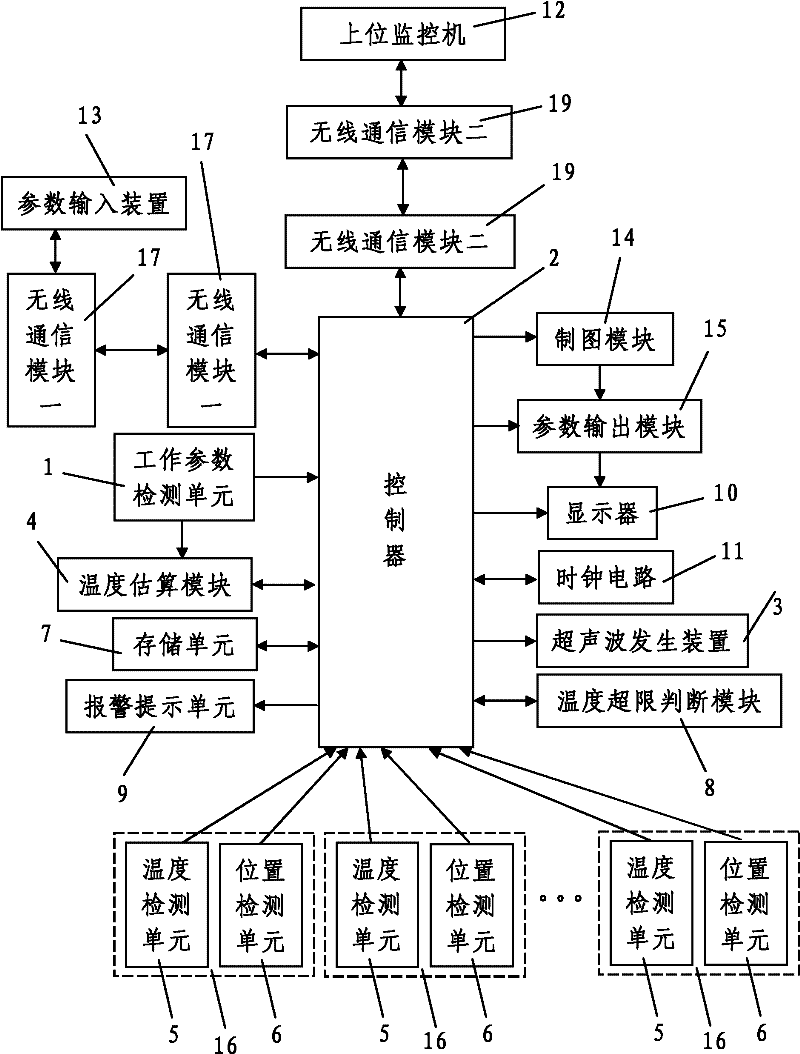

[0030] Such as figure 1 As shown, the present invention includes a working parameter detection unit 1 for real-time detection of the relevant working parameters of the ultrasonic generating device 3 used by a plastic welding machine, a controller 2 for correspondingly controlling the ultrasonic generating device 3, and a detection unit 1 according to the working parameter detecting unit 1. Information temperature estimation module 4 for estimating the hot melt temperature of the welded area, temperature detection unit 5 for real-time detection of the surface temperature of the welded plastic products around the welded area, and detection of the position of the temperature detection unit 5 The position detection unit 6, the clock circuit 11 connected with the controller 2, the storage unit 7 that internally stores the hot melt temperature data corresponding to various plastic materials, according to the information detected by the temperature detection unit 5 and the position de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com