Material guiding device of vertical pre-heater

A vertical preheater and introduction device technology, applied in the direction of preheating costs, lighting and heating equipment, furnaces, etc., can solve the problems of large space occupation, high consumption of heat-resistant steel, complex structure, etc., and achieve easy installation, adjustment and replacement , the sealing form is reasonable, and the effect of smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

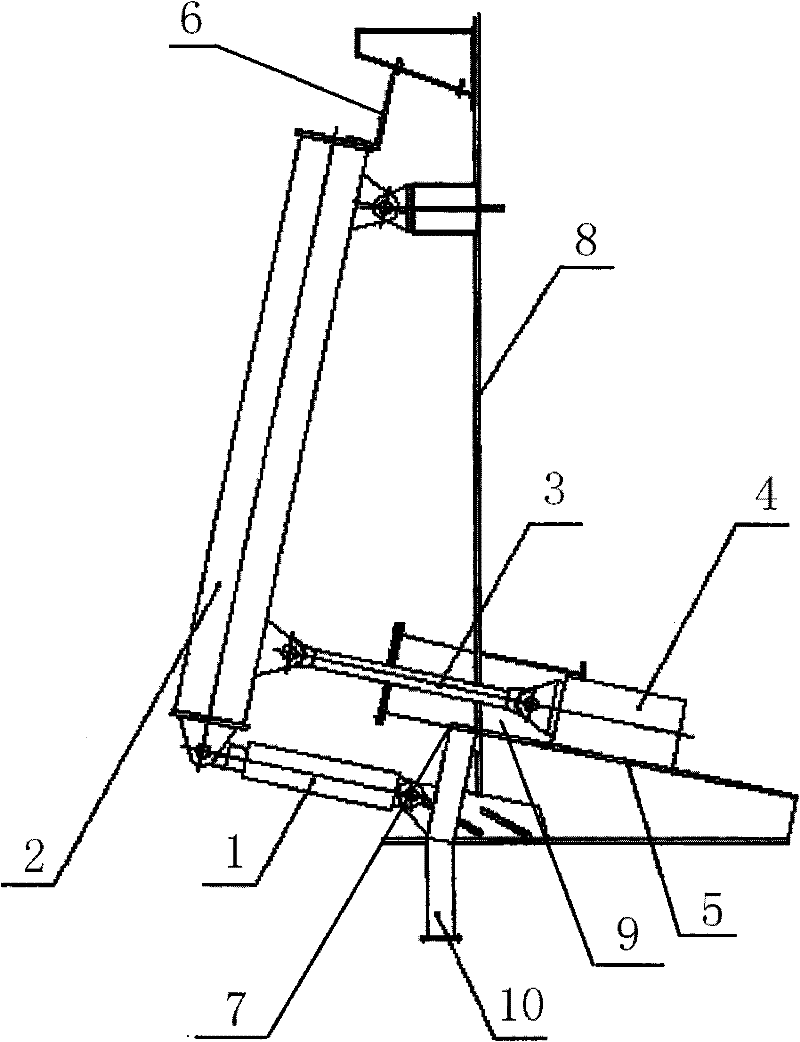

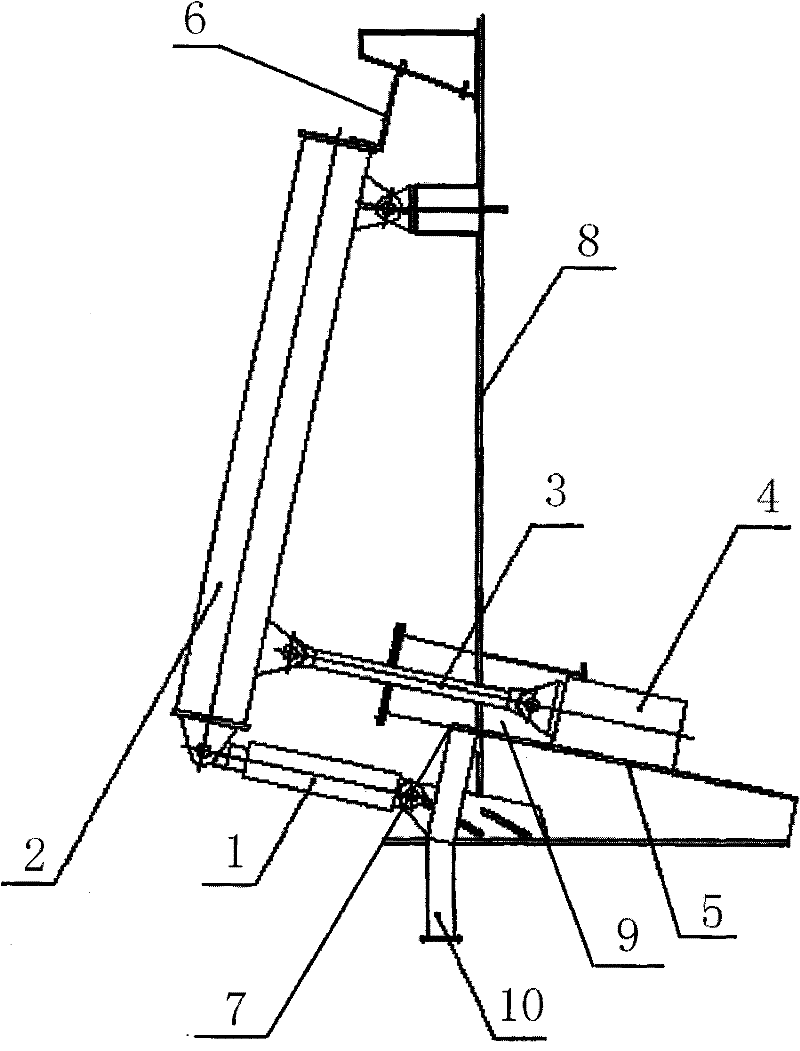

[0012] Below in conjunction with accompanying drawing and embodiment, the present invention is described in further detail, but does not constitute any restriction to the present invention:

[0013] see figure 1 As shown, a vertical preheater material introduction device includes a hydraulic push rod 1, a frame 2, a connecting rod 3, a material guide rod 4, a guide rail 5, a limiting part 6, a sealing structure 7 and a preheater body 8, One end of the hydraulic push rod 1 is hinged to the preheater body 8, the piston rod of the hydraulic push rod 1 is hinged to the lower end of the frame 2, and the upper end of the frame 2 is hinged to the preheater body 8. On the preheater body 8 corresponding to the position of the upper end of the frame 2, a limiting part 6 is arranged, the frame 2 is hinged with one end of the connecting rod 3, the other end of the connecting rod 3 is hinged with the guide rod 4, and the guide rod 4 is hinged. The material rod 4 is arranged on the guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com