Pipeline built-in decompressing throttling valve for low-temperature system

A low-temperature system and throttle valve technology, which is applied in the direction of pipe components, safety valves, balance valves, etc., can solve the problems of joint seal leakage, sealing surface leakage, and high risk, so as to reduce the installation process, effectively manage and save material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

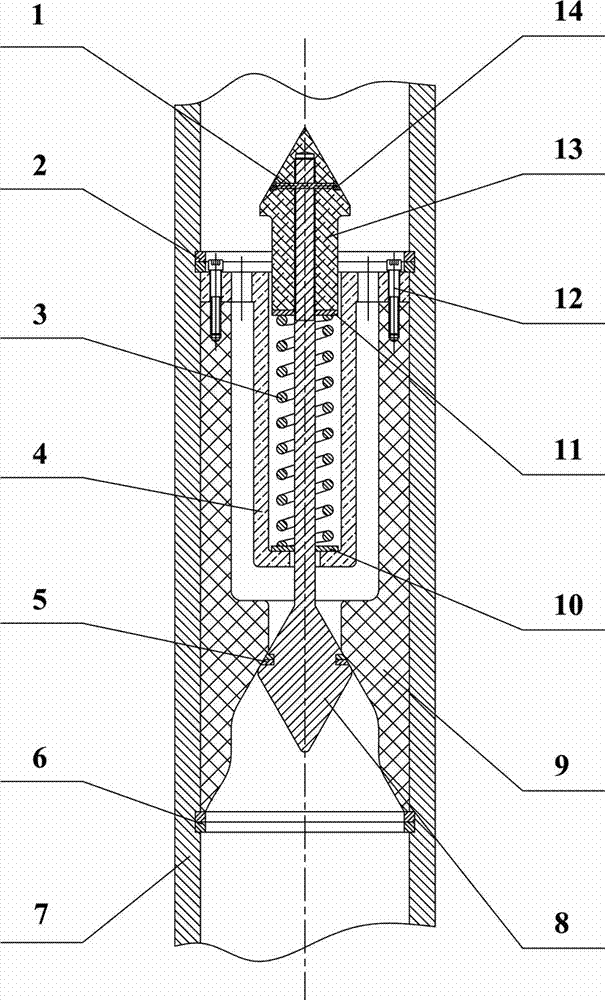

[0017] Correct the prestress of the spring 3 under low temperature conditions, so that the prestress of the ballistic 3 is consistent with the working pressure of the pipeline; intercept the part to install the pipeline 7 and process the upper and lower grooves in the pipeline 7, and install the processed valve in the pipeline 7 , and then install the upper clamp 2 and the lower clamp 6; weld the installed pipeline 7 into the process pipeline; adjust the low pressure control pressure of the pipeline to the corresponding fluid working pressure, if the internal pressure exceeds the working pressure, the pressure reducing throttle valve The low-pressure end is automatically opened to relieve pressure in a throttling manner and produce a throttling refrigeration effect. When the system pressure is lower than the working pressure, the decompression and throttling valve is automatically closed.

[0018] The specific process is as follows:

[0019] Slowly open the main switch valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com