Doffer and yarn winding apparatus including the same

A technology of doffing and winding, which is used in transportation and packaging, textiles and papermaking, and transportation of filamentous materials, etc., can solve problems such as complicated mechanisms, and achieve the effects of simplifying structure, preventing quality degradation, and preventing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

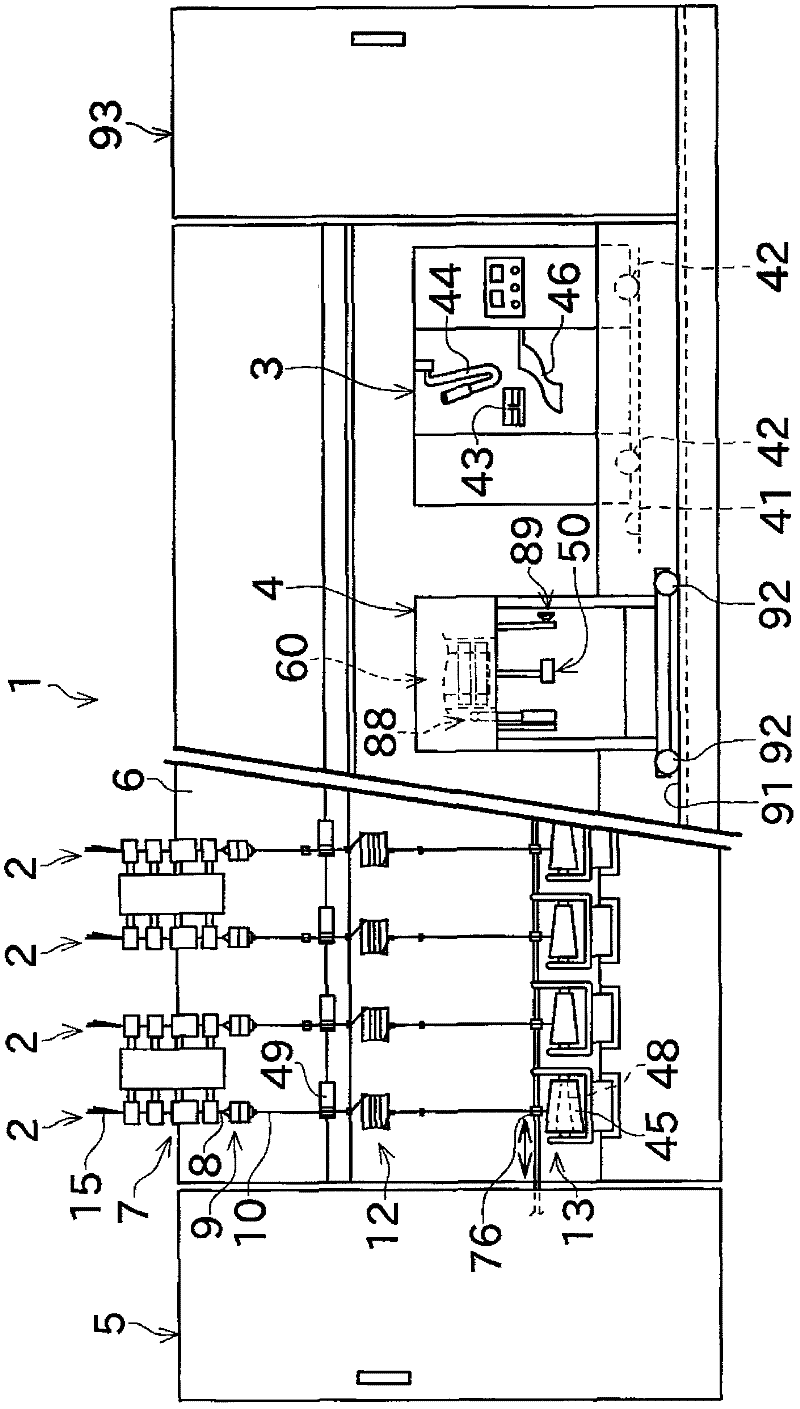

[0042] Next, a spinning frame (winding frame) according to an embodiment of the present invention will be described with reference to the drawings. In addition, "upstream" and "downstream" in this specification refer to upstream and downstream in the moving direction of the yarn during spinning. figure 1It is a front view showing the structure of the whole spinning frame 1.

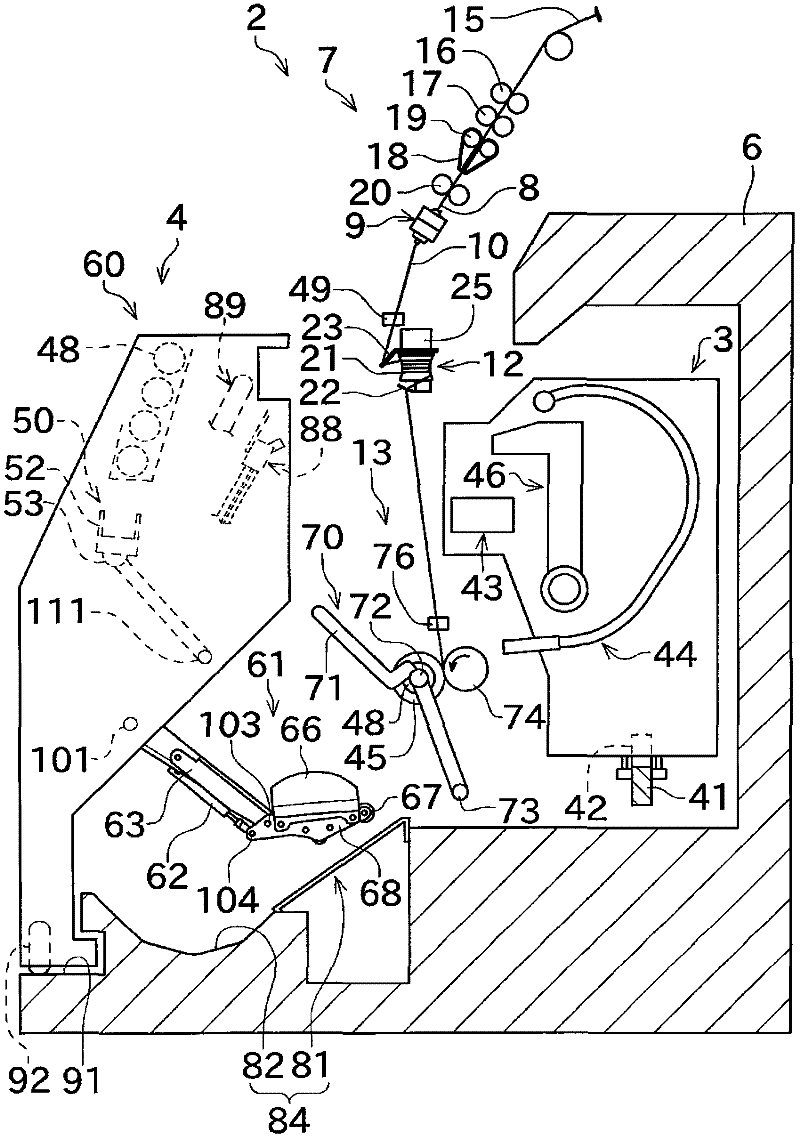

[0043] figure 2 It is a longitudinal sectional view of the spinning frame 1.

[0044] as figure 1 The spinning frame 1 of the shown winder includes a plurality of spinning units 2 arranged side by side. The spinning frame 1 includes a yarn joining cart 3 , a doffing cart 4 , a blower box 93 , and a prime mover box 5 .

[0045] Such as figure 1 As shown, each spinning unit 2 mainly includes a draft device 7, a spinning device 9, a yarn storage device 12, and a winding device 13 arranged in the following order from upstream to downstream. The draft device 7 is provided near the upper end of the frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com