Rolled product tension control device, rolled product tension control method and hot strip mill

A technology of tension control and hot continuous rolling mill, applied in the direction of tension/pressure control, etc., can solve the problems of control input signal changes, not necessarily the same tension, different precision and performance, etc., and achieve the effect of stable tension control and continuous tension control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

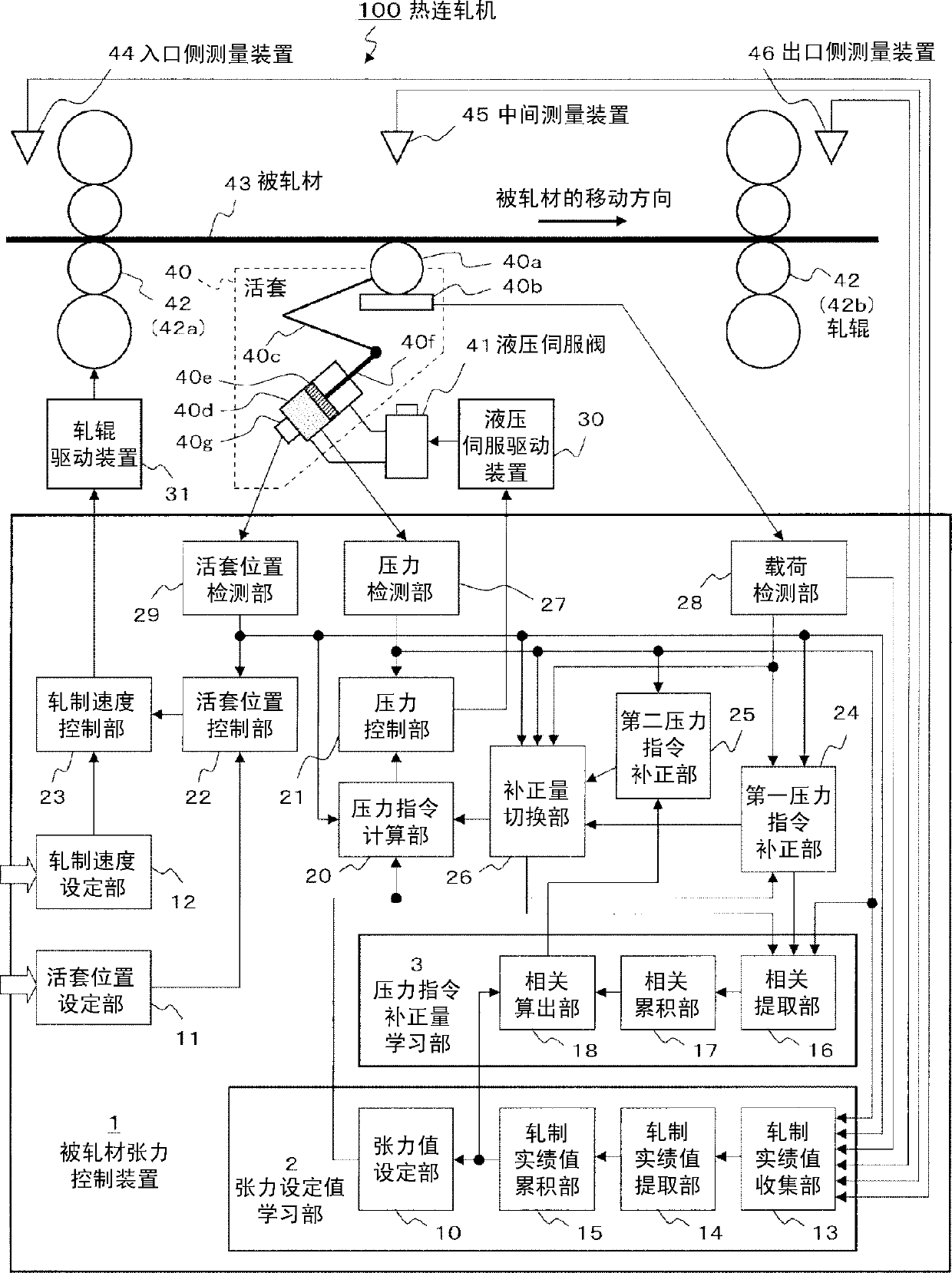

[0067] figure 1 It is a figure which shows the example of the structure of the to-be-rolled material tension control apparatus and the to-be-rolled material tension control apparatus which are equipped with this to-be-rolled material tension control apparatus concerning embodiment of this invention.

[0068] The hot continuous rolling mill 100 is a device for continuously rolling a high-temperature rolled material 43 by rolls 42 respectively arranged on a plurality of supports not shown in the figure. The looper 40 and the hydraulic servo drive 30 to the tension of the rolled material 43 . In addition, this hot continuous rolling mill 100 has a rolling material tension control device 1 for controlling the looper 40 and the hydraulic servo drive device 30 .

[0069] exist figure 1 In this process, the roll 42 rotates at a predetermined speed and rolls the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com