Method for preparing alumina carrier

An alumina carrier and alumina technology, which is applied in catalyst carriers, chemical instruments and methods, alumina/aluminum hydroxide, etc., can solve the problems affecting the mechanical strength of alumina carriers, large particle size, etc., and achieve volume reduction and improvement. The effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

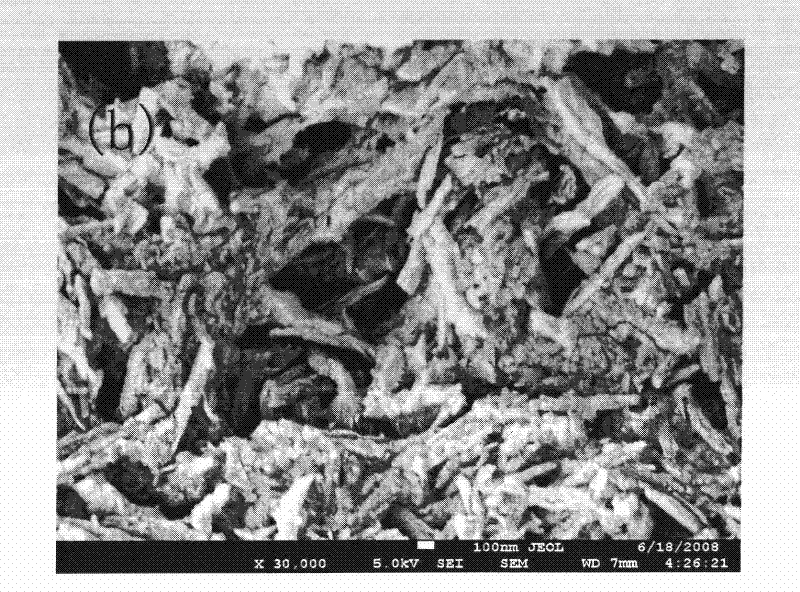

[0043] Under stirring conditions, 375g of aluminum nitrate nonahydrate and 90g of urea were mixed and heated to 100°C, and added to a mixture of 32g of polyisobutylene maleate triethanolamine maleate and 88g of 150HVI neutral oil at the same temperature to form supersolubilizing micelles , and then reacted at 100°C for 3 hours to obtain nano-aluminum hydroxide gel. Wash three times with 200ml of distilled water, and dry at 120°C for 10 hours. Under normal pressure, extract with diesel oil at 70°C, the volume ratio of diesel oil to nano-aluminum hydroxide xerogel is 2:1, the extraction time is 5 hours, and the number of extractions is three times, then filter, and dry at 100°C for 5 hours, Obtain nano aluminum hydroxide AH1.

[0044] 100g of nano-aluminum hydroxide AH1, 5g of dilute nitric acid (mass concentration 17%), and 60g of water were mixed evenly, and mixed evenly on a mixer, and then formed in an extruder, and the pressure was controlled at 10MPa. The molded product ...

Embodiment 2

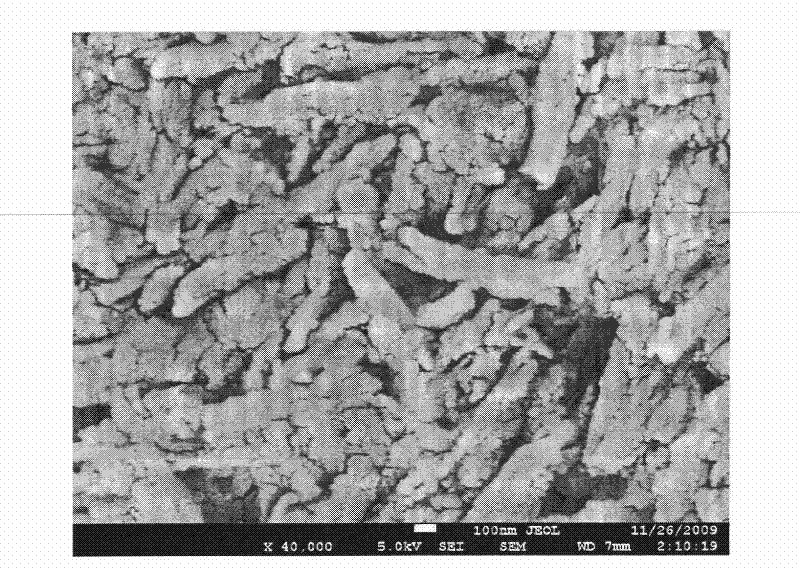

[0049] Under stirring conditions, 548g of aluminum nitrate nonahydrate and 132g of urea were mixed and heated to 70°C, and added to the mixture of 120g of polyisobutylene maleate triethanolamine maleate and 200g of 150HVI neutral oil at the same temperature to form supersolubilizing micelles , and then reacted at 150° C. for 8 hours to obtain nano-aluminum hydroxide gel. Wash three times with 200ml of distilled water, and dry at 120°C for 10 hours. Under normal pressure, extract with xylene at 70°C, the volume ratio of xylene to nano-aluminum hydroxide xerogel is 3:1, the extraction time is 3 hours, and the number of extractions is three times, then filter, and dry at 100°C for 5 hours, the obtained nano aluminum hydroxide AH2.

[0050] 100g nano-aluminum hydroxide AH2 and binding agent pseudo-boehmite are mixed uniformly in a weight ratio of 9: 1; 2.4g dilute nitric acid (mass concentration 17%), 75g water are mixed uniformly, and then added to nano-aluminum hydroxide and I...

Embodiment 3

[0055] Under stirring conditions, 548g of aluminum nitrate nonahydrate and 170g of urea were mixed and heated to 70°C, and added to a mixture of 25g of polyisobutylene maleate triethanolamine maleate and 95g of 150HVI neutral oil at the same temperature to form supersolubilizing micelles , and then reacted at 150° C. for 8 hours to obtain nano-aluminum hydroxide gel. Wash three times with 200ml of distilled water, and dry at 120°C for 10 hours. Under normal pressure, extract with petroleum ether at 50°C, the volume ratio of petroleum ether to nano-aluminum hydroxide xerogel is 1:1, the extraction time is 8 hours, and the number of extractions is three times, then filter, and dry at 100°C for 5 hours, the obtained nano aluminum hydroxide AH3.

[0056] 100g nanometer aluminum hydroxide AH3 and comparative example 1 DAH1 are mixed uniformly by weight 3: 1; 2.4g dilute nitric acid (mass concentration 17%), 75g water are mixed homogeneously, then molding in extruder, control press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com