Multilayer single-face aluminum-based circuit board and manufacturing method thereof

An aluminum-based circuit board, single-sided technology, applied in the fields of printed circuit manufacturing, chemical instruments and methods, layered products, etc., can solve problems such as poor thermal conductivity, temperature rise of circuit boards, and hindrance of heat conduction of inner layer boards , to improve the effect of heat conduction, increase the contact surface, and improve the effect of heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

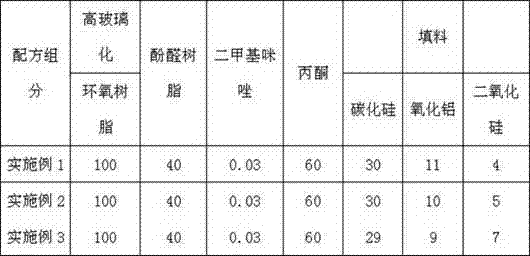

Embodiment 1

[0028] A three-layer single-sided aluminum-based circuit board is prepared by the following method:

[0029] (1) Preparation of epoxy resin glue: prepare glue with high vitrification epoxy resin, phenolic resin, dimethylimidazole and acetone according to the following weight components, mix evenly and mature for 2 to 6 hours;

[0030] 100 parts of high vitrification epoxy resin;

[0031] 40 parts of phenolic resin;

[0032] 0.03 parts of dimethylimidazole;

[0033] 60 parts of acetone;

[0034] (2) Preparation of nano-inorganic composite fillers: taking the quality of epoxy resin as a benchmark, silicon carbide, aluminum oxide and silicon dioxide are configured with fillers according to the following weight components, and mixed uniformly;

[0035] 30 parts of silicon carbide;

[0036] 11 parts of aluminum oxide;

[0037] 4 parts of silicon dioxide;

[0038] (3) Prepare a high thermal conductivity insulating adhesive solution: add all the nano-inorganic composite filler...

Embodiment 2

[0042] A four-layer single-sided aluminum-based circuit board is prepared by the following method:

[0043] (1) Prepare epoxy resin glue: prepare glue with high vitrification epoxy resin, phenolic resin, dimethylimidazole and acetone according to the following weight components, mix evenly and mature for 2 hours;

[0044] 100 parts of high vitrification epoxy resin;

[0045] 40 parts of phenolic resin;

[0046] 0.03 parts of dimethylimidazole;

[0047] 60 parts of acetone;

[0048] (2) Preparation of nano-inorganic composite filler: based on the quality of epoxy resin, silicon carbide, aluminum oxide and silicon dioxide are configured as fillers according to the following weight components, and mixed uniformly;

[0049] 30 parts of silicon carbide;

[0050] 10 parts of aluminum oxide;

[0051] 5 parts of silicon dioxide;

[0052] (3) Prepare a high thermal conductivity insulating adhesive solution: add all the nano-inorganic composite fillers prepared in step 2 to the e...

Embodiment 3

[0056] A six-layer single-sided aluminum-based circuit board is prepared by the following method:

[0057] (1) Prepare epoxy resin glue: prepare glue with high vitrification epoxy resin, phenolic resin, dimethylimidazole and acetone according to the following mass components, mix well and mature for 2 hours;

[0058] 100 parts of high vitrification epoxy resin;

[0059] 40 parts of phenolic resin;

[0060]0.03 parts of dimethylimidazole;

[0061] 60 parts of acetone;

[0062] (2) Prepare nano-inorganic composite fillers: prepare fillers with silicon carbide, alumina and silicon dioxide according to the following mass components, and mix them evenly;

[0063] 29 parts of silicon carbide;

[0064] 9 parts of aluminum oxide;

[0065] 7 parts of silicon dioxide;

[0066] (3) Prepare a high thermal conductivity insulating adhesive solution: add all the nano-inorganic composite fillers prepared in step 2 to the epoxy resin glue prepared in step 1, and mix evenly;

[0067] (4)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com