Dynamic contact resistance testing device of conducting ring

A technology of dynamic contact resistance and test device, applied in the field of conductive rings, can solve the problems of low test accuracy, inability to carry out continuous dynamic test, low efficiency, etc., and achieve the effect of reducing human factors, improving work efficiency and test accuracy, and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

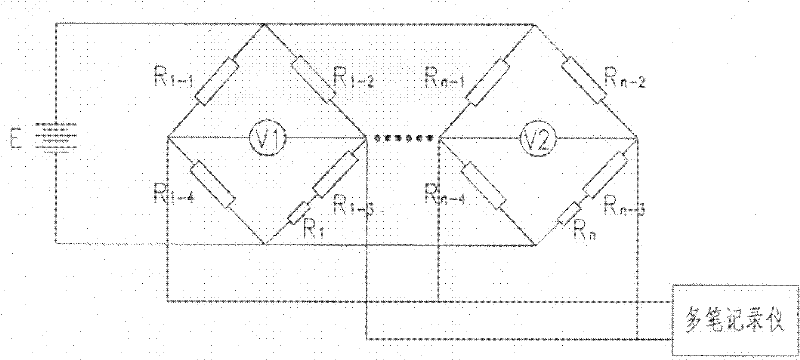

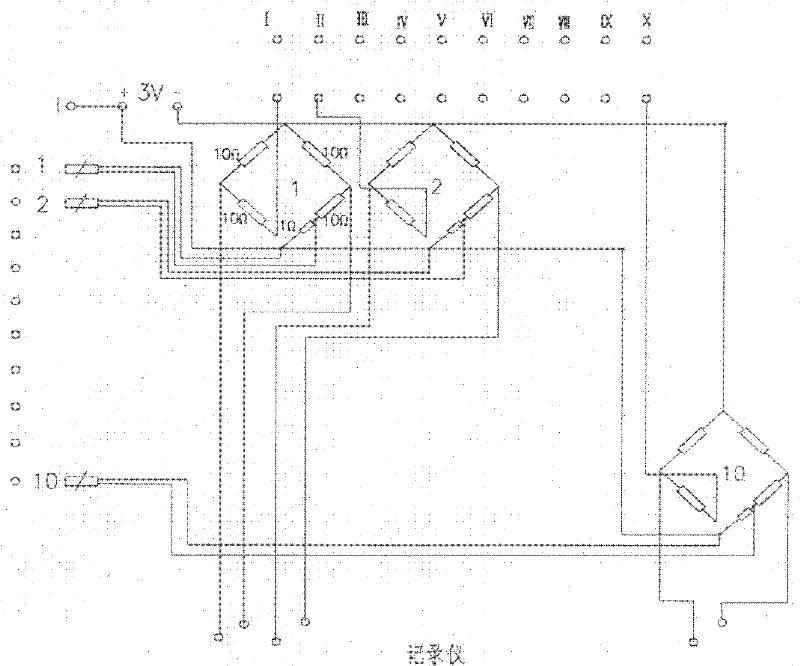

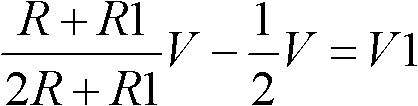

[0013] The utility model relates to a dynamic contact resistance testing device of a conductive ring, which is realized by testing based on the principle of an electric bridge. The testing principle of the present invention is as figure 1 As shown, the test circuit consists of a standard resistor R of the same resistance 1-1 , R 1-2 …R n-1 , R n-2 Form stable N bridges, according to the principle of the bridge, the output voltage V at this time 1 , V 2 …V N is zero, and each contact resistance R of the power transmission device (conductive ring) 1 …R n After each bridge is introduced separately, the balance of each bridge is destroyed, and the output voltage V of each bridge 1 , V 2 …V N Sampling and recording can be carried out by multiple recorders, and finally the recorded voltage value can be calculated through the bridge balance the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com