Integrated alkali metal carrier dynamic desorption device

An alkali metal, integrated technology, applied in the field of chemical applications, can solve the problems of changes in physical and chemical properties, great threat to personnel and property safety, easy oxidation, etc., to prevent oxidation and improve the quality of desorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

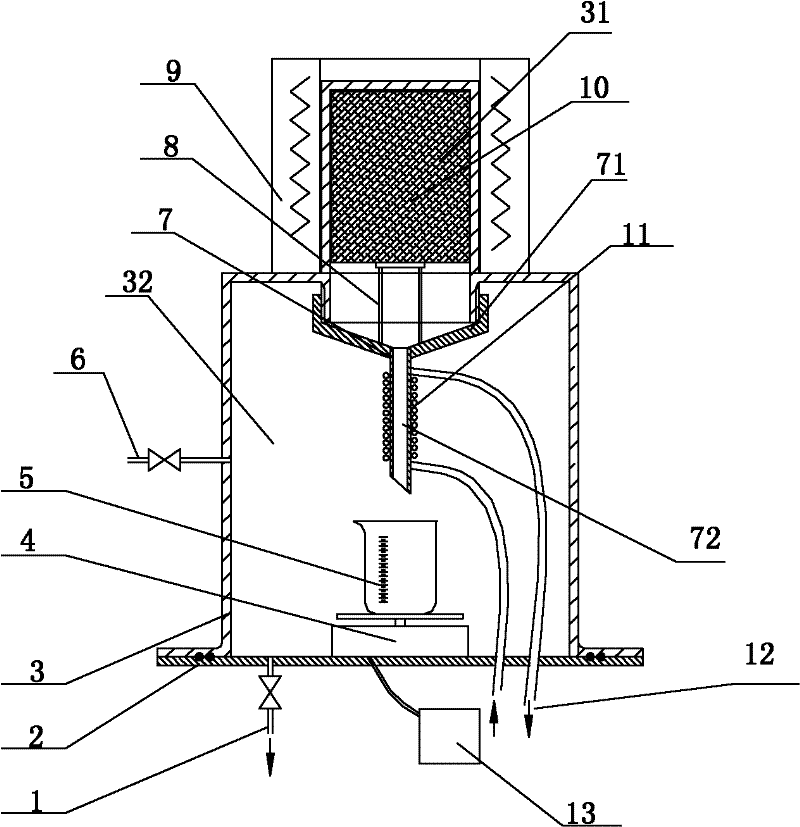

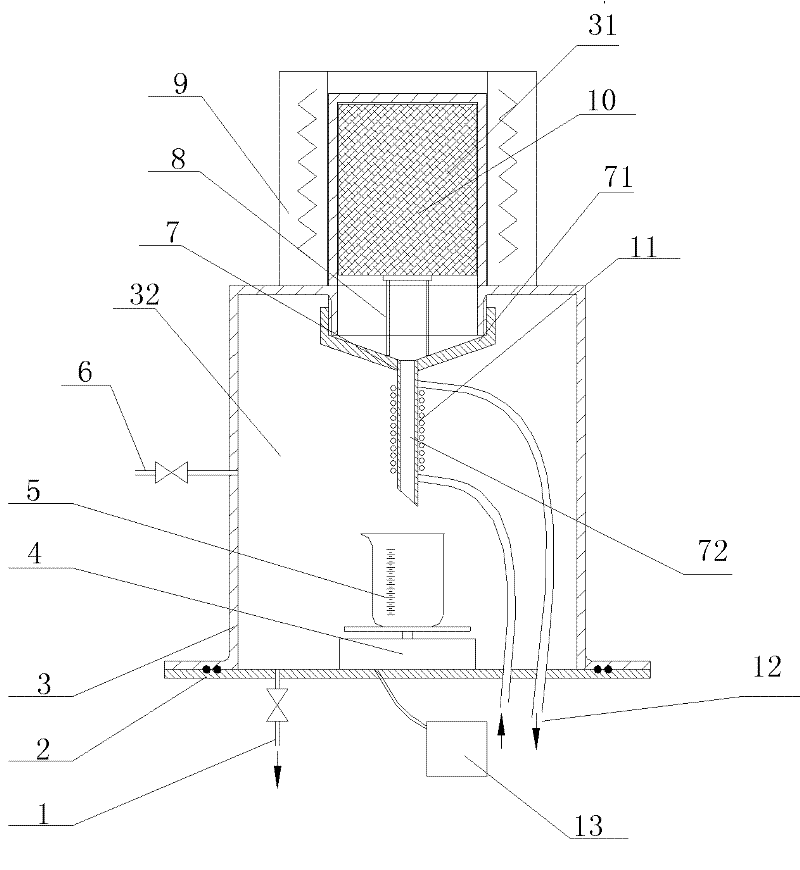

[0029] The composition of the integrated alkali metal carrier dynamic desorption device includes: the vacuum chamber 3 is divided into upper and lower sections, the upper section is a hot zone vacuum chamber, and the lower section is a cold zone vacuum chamber; Coil) 9, the inner side is a cavity for heating the alkali metal carrier 10; the vacuum chamber in the cold zone and the sealing flange 2 form a sealed cabin through O-rings and bolts; the sealing flange 2 is provided with a vacuum valve 1, a condensation pipe 12 interface and signal line interface; the current collector 7 is combined with the upper section through threads in the vacuum chamber 3, and supports the alkali metal carrier to the heating area of the resistance furnace 9 through the support frame 8; the drainage tube under the current collector 7 A condenser 11 is installed outside; the collection cup 5 in the vacuum chamber 3 is placed on the load cell 4, and the load cell 4 is connected to the display reco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com