Method for improving overloading response speed of silicon capacitive pressure sensor

A technology of pressure sensor and overload response, which is applied in the direction of fluid pressure measurement, instrument, and measurement force using capacitance changes, and can solve the problems of improving the overload response speed of silicon capacitance pressure sensors, etc., with remarkable effect and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

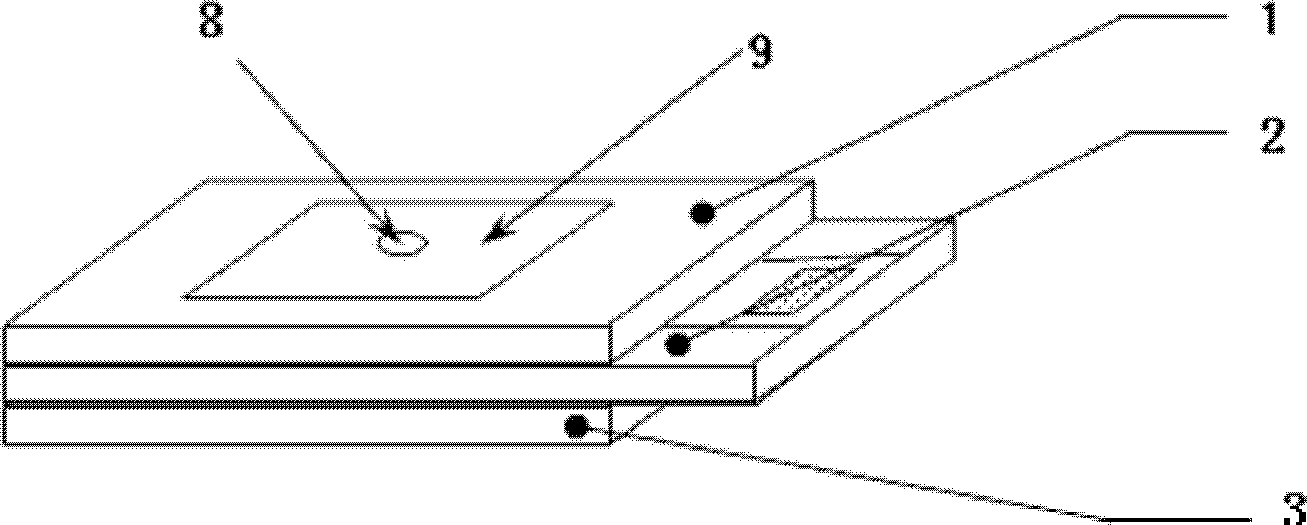

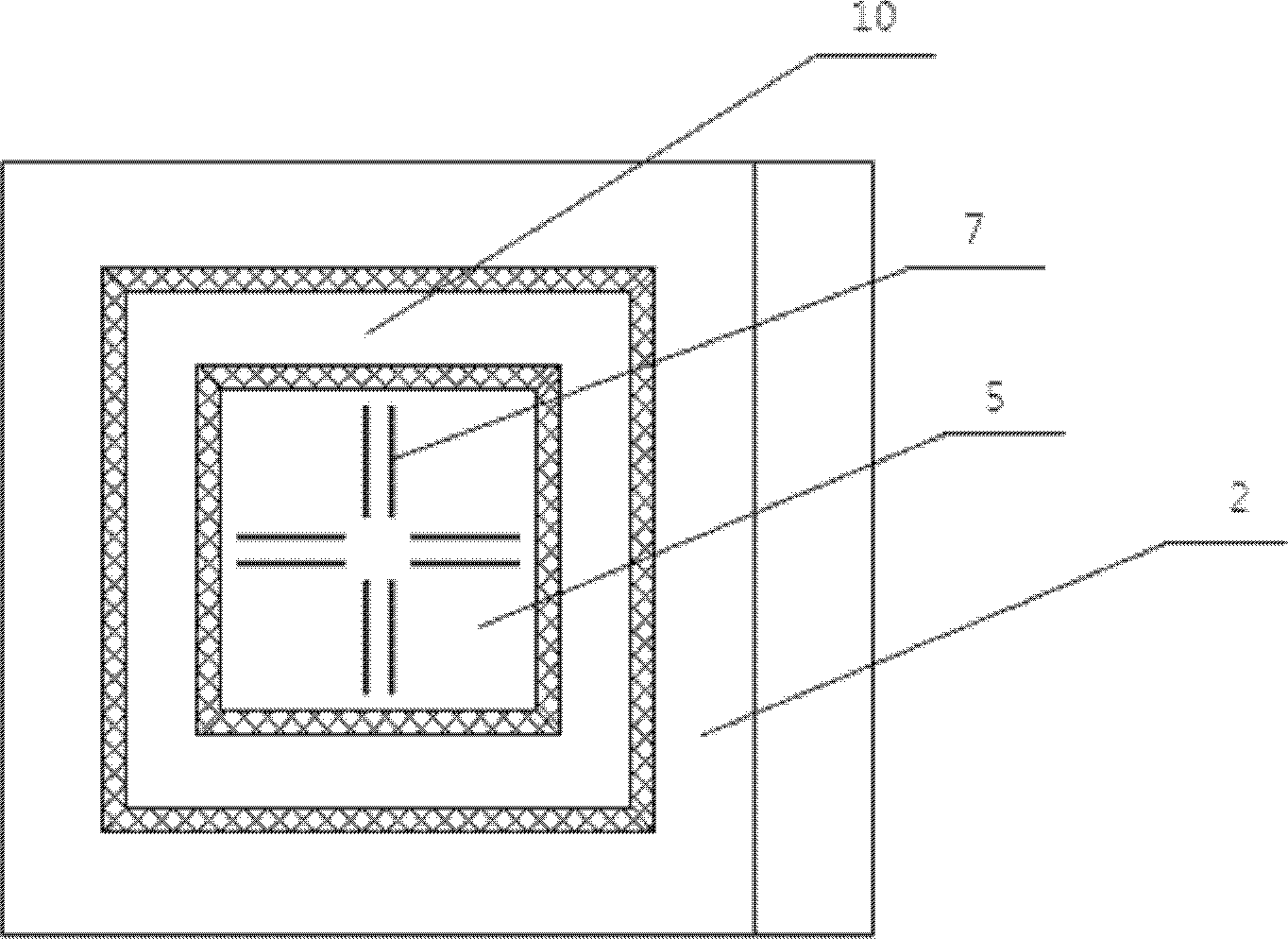

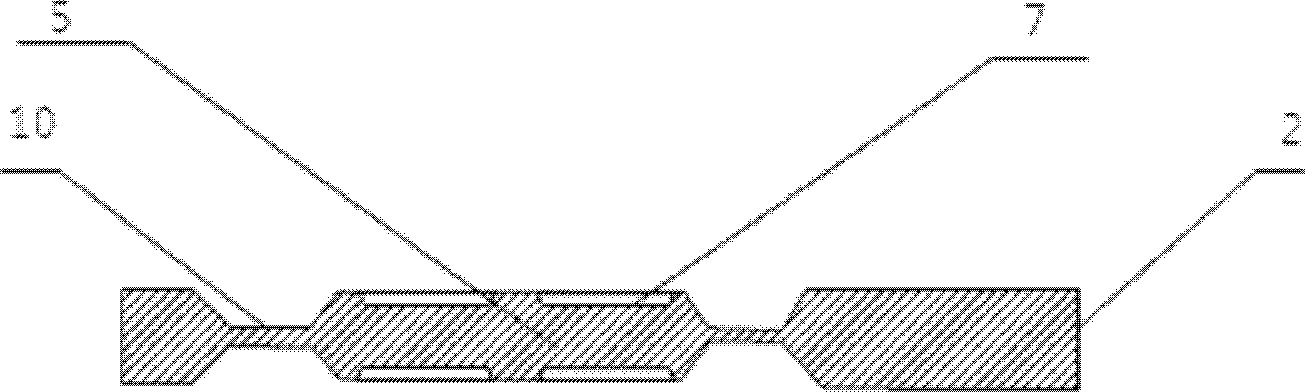

[0020] The method to improve the overload response speed of the silicon capacitive pressure sensor is to use the electrostatic sealing process to seal the capacitive three-electrode plate into a sandwich structure, such as figure 1 As shown, the upper glass fixed plate 1 and the lower glass fixed plate 3 have the same structure, and there is silicone oil filling between the silicon sensitive chip movable plate 2 and the upper and lower glass fixed plates 1 and 3 for pressure Transmission; it is characterized in that there is a square center island 5 on the movable plate 2 of the silicon sensitive chip sandwiched between the upper glass fixed plate 1 and the lower glass fixed plate 3, and the oil guide groove structure is designed on both sides of the center island 5 , and use MEMS processing technology to make linear oil guide groove 7, see figure 2 , image 3 , at the opposite inner surfaces and central holes of the upper and lower glass fixed pole plates 1 and 3, a metal s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com