Circulating water feeding system of cooling device of hydropower generation set

A technology for generating sets and cooling devices, which is applied to household refrigeration devices, lighting and heating equipment, household appliances, etc., and can solve the problems of ensuring the normal operation of hydraulic generating sets, affecting the normal operation of hydraulic generating sets, making it difficult to soften cooling water, and In order to achieve the effect of convenient inspection and maintenance of coolers, improve safe and reliable operation, and save inspection and maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

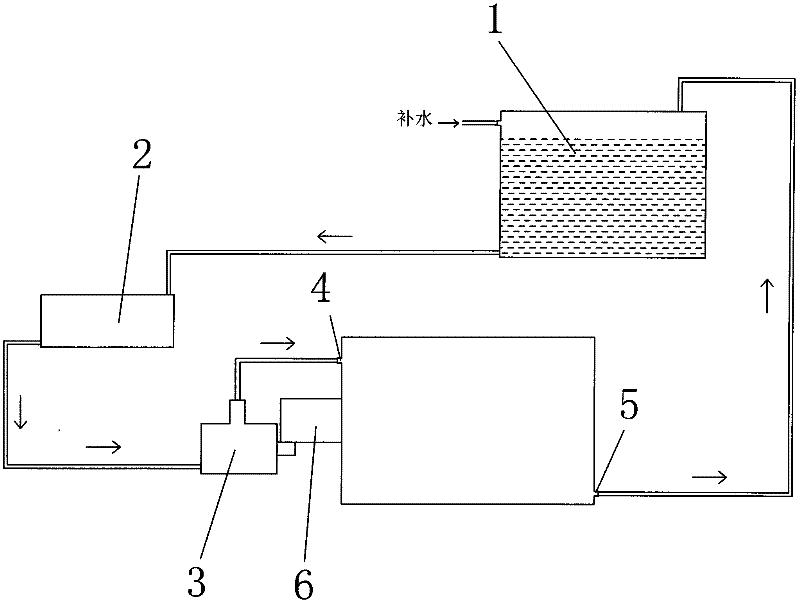

[0022] Such as figure 1 Shown is a structural schematic diagram of the circulating water supply system of the cooling device of the hydraulic generating set. The circulating water supply system of the cooling device of the hydropower generating set, including the circulating water pool 1, the cooler 2, the mechanical water pump 3 and the automatic water supply device, the circulating water pool 1, the cooler 2 and the mechanical water pump 3 are connected by pipelines in turn; the cooling device of the bearing seat of the hydraulic generating set The water inlet 4 of the air cooler is connected to the water outlet of the mechanical water pump 3, and the water outlet 5 of the bearing block cooling device of the water conservancy generator set and the air cooler is connected to the circulating water pool 1; 6 Drive work; the circulating pool 1 is a closed pool, and there is an automatic water supply device inside; the elevation of the circulating pool 1 is 3 to 5 meters higher t...

Embodiment 2

[0025] The specific implementation method is the same as that of Embodiment 1, except that the elevation of the circulating pool 1 is 4 meters higher than the elevation of the hydraulic generator unit; the mechanical water pump 3 is connected to the rotor shaft 6 of the hydraulic generator unit through a belt.

Embodiment 3

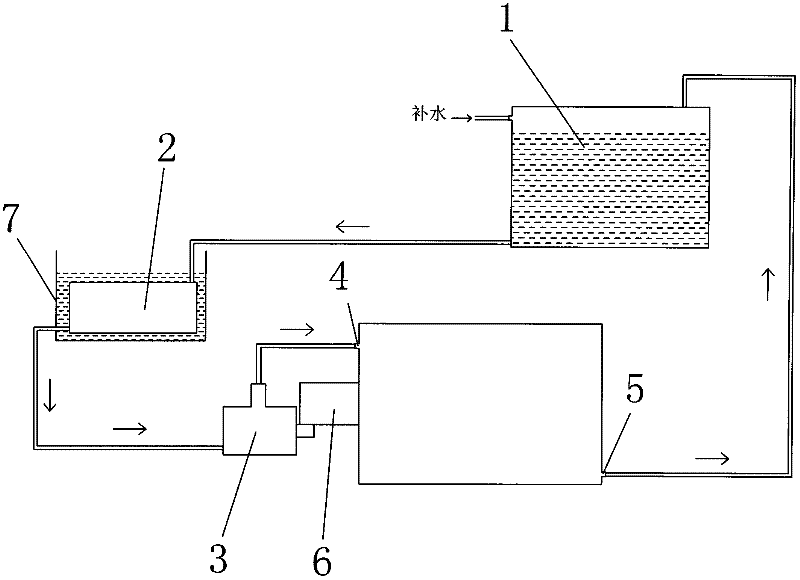

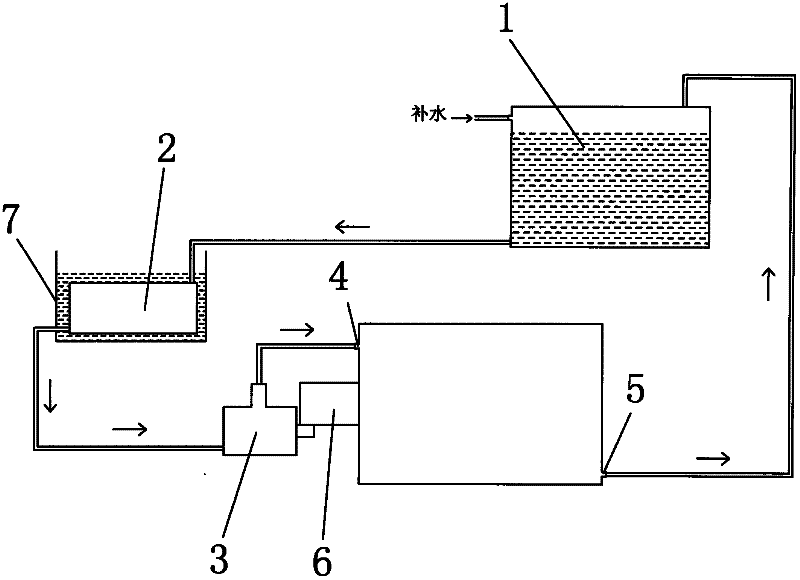

[0027] Such as figure 2 , the specific implementation is the same as in Example 2, the difference is that the elevation of the circulating pool 1 is 5 meters higher than the elevation of the hydraulic generator unit; the cooler 2 is submerged in the cooling pool 7, and the cooling pool 7 is provided with water inlet and drain pipes Flowing water is in the cooling pool 7, and the flowing water is the forebay water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com