Micro-oil ignition burner

A technology for igniting a burner and a small amount of oil, which is applied to burners, burners for burning powder fuel, and combustion methods, etc. problems, to achieve the effect of wide adaptability of coal types, high cost performance, moderate investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

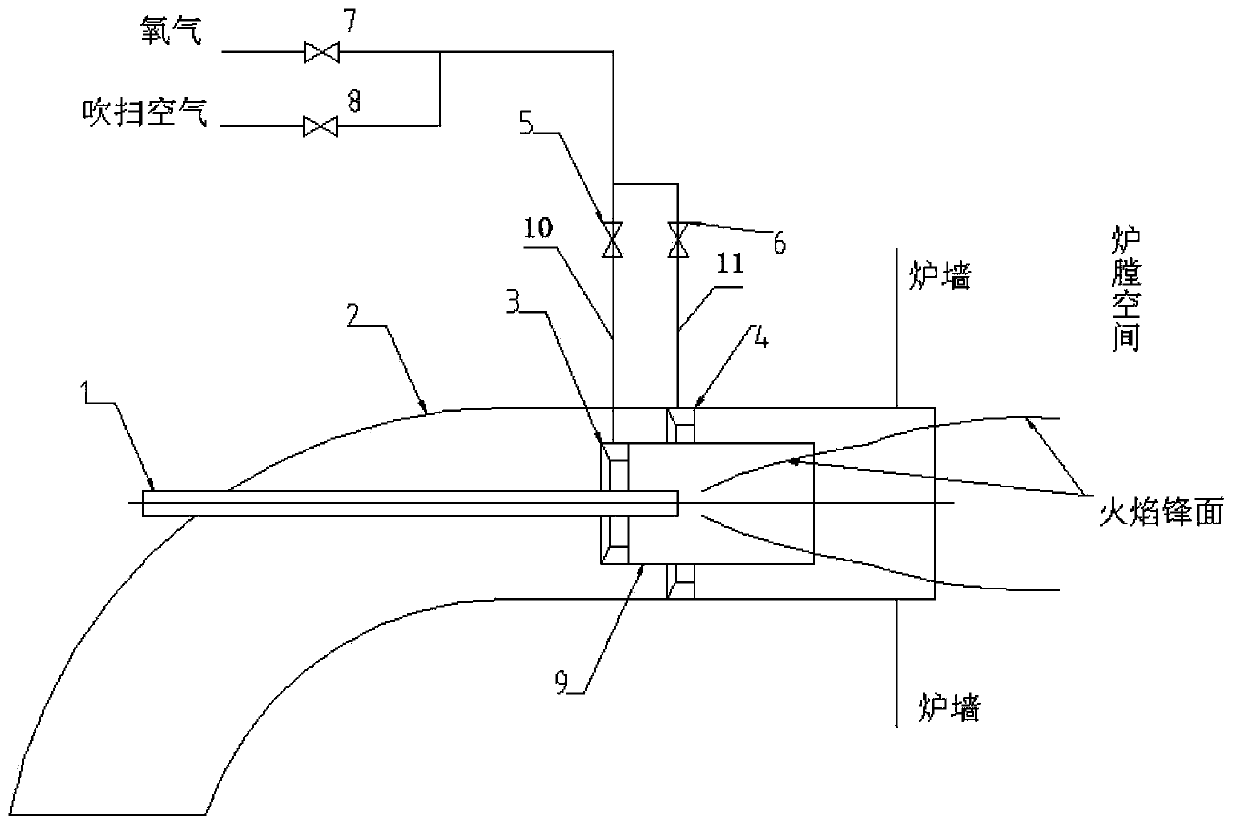

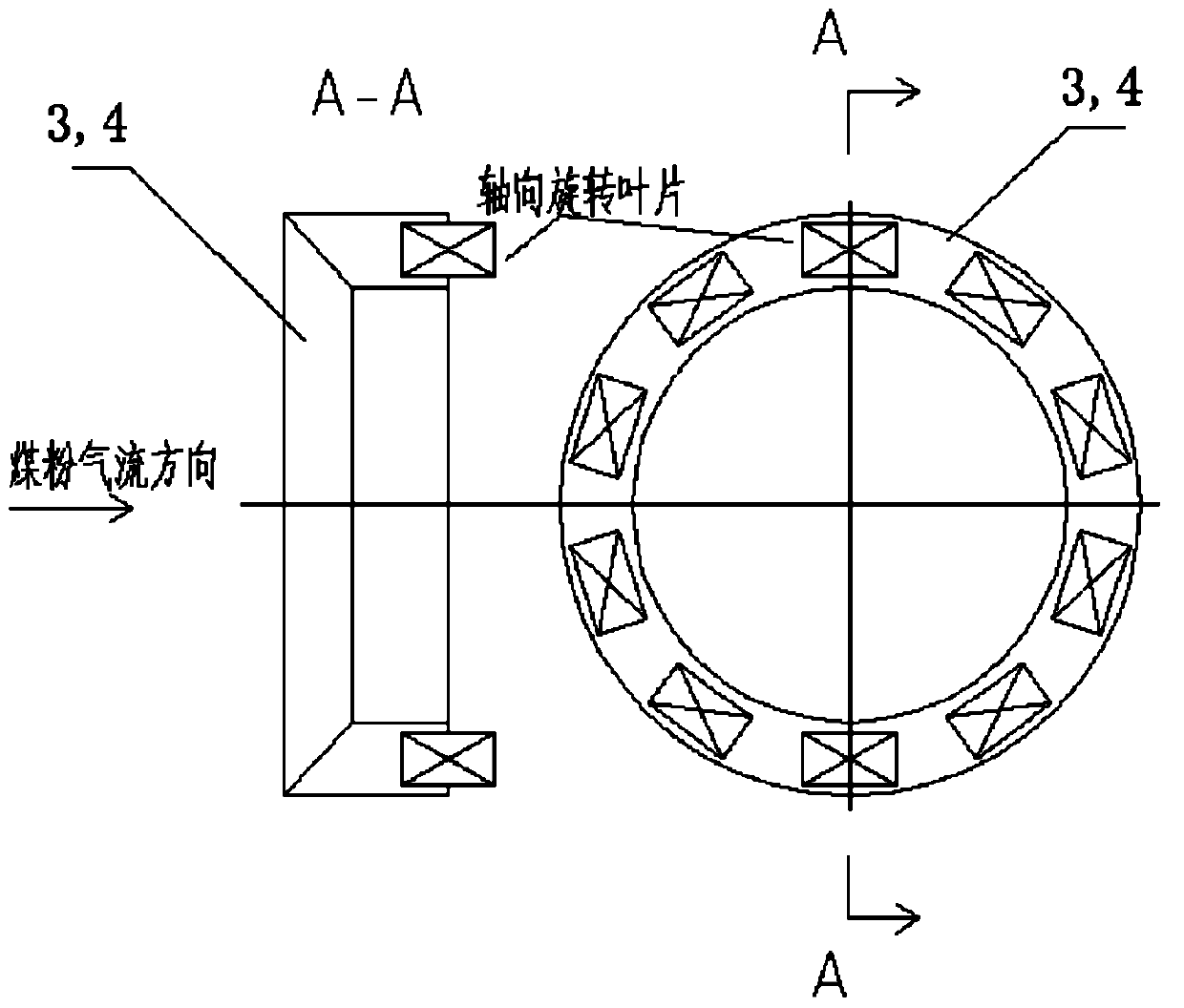

[0024] refer to figure 1 , image 3 and Figure 4 , A micro-oil ignition burner in an oxygen-enriched environment of the present invention includes a small oil gun 1 and a burner 2 for micro-oil gasification. The burner 2 contains a sleeve 9, and the small oil gun 1, the burner 2 and the sleeve 9 are arranged in a coaxial direction. The first oxygen conduit 3 is installed on the inner wall of the left end of the sleeve 9 facing the direction of the pulverized coal gas flow. In addition to providing oxygen, the first oxygen conduit 3 also acts as a pulverized coal concentration ring. The first oxygen conduit 3 faces the pulverized coal. The outer side of the pipe wall in the direction of the pulverized gas flow is made of wear-resistant metal, and the first oxygen conduit 3 is arranged with an axial rotating blade on the pipe wall facing away from the direction of the pulverized coal gas flow. A local oxygen-enriched zone is formed in the sleeve 9 and adjacent areas. The se...

Embodiment 2

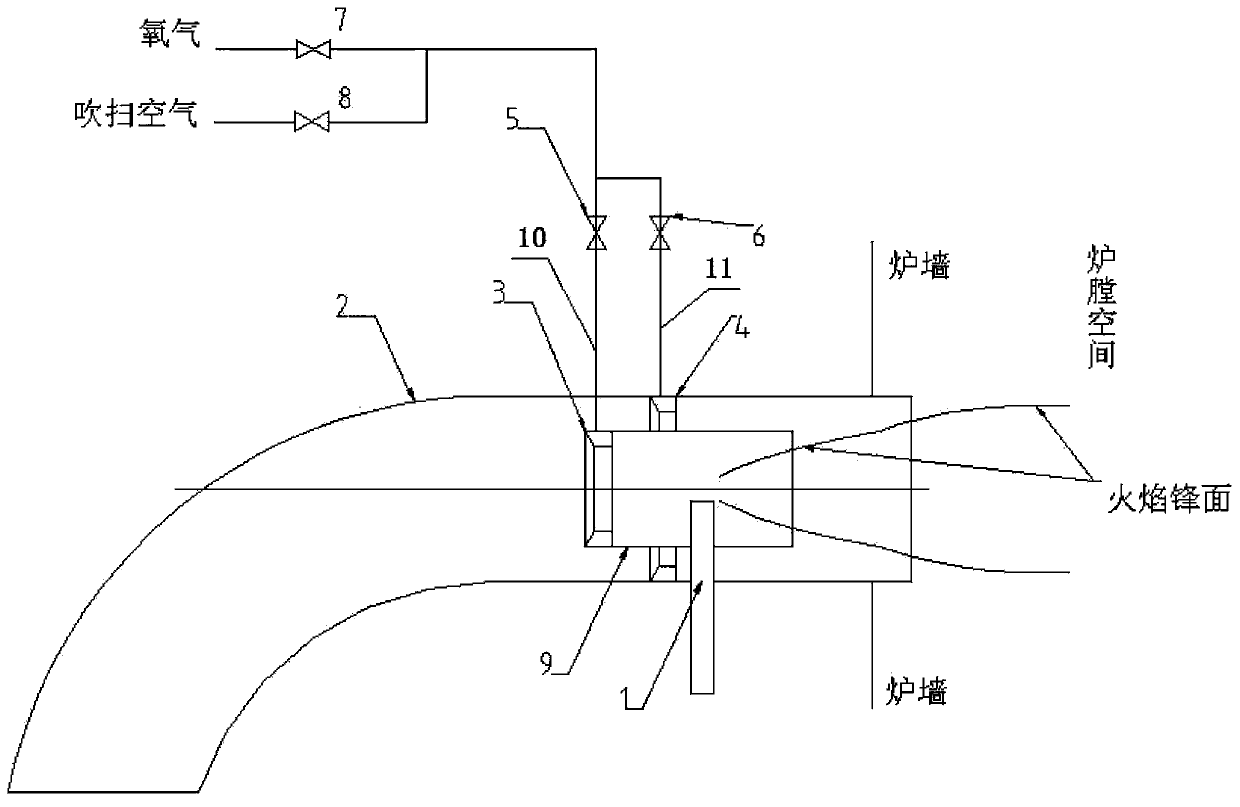

[0028] refer to figure 2 , image 3 and Figure 4 , the difference between this embodiment and Embodiment 1 is that the micro-gasification small oil gun 1 is inserted into the burner from the radial direction of the burner 2, and the high-temperature smoke after the gasification oil mist emitted by the micro-gasification small oil gun is burned Gas can be filled in the sleeve 9 .

Embodiment 3

[0030] refer to image 3 As shown, in this embodiment, the cross-sectional shape of the oxygen conduit is a trapezoid, and the wall surface facing the direction of the pulverized coal gas flow is surfacing with anti-wear metal or anti-wear ceramics. Axial rotating blades are arranged on the wall surface away from the direction of the pulverized coal gas flow, and oxygen enters the burner in a swirling manner to be mixed with the pulverized coal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com