Double-mode type full-variable valve driving system for four-cylinder internal combustion engine

A driving system and internal combustion engine technology, applied in the direction of valve driving devices, machines/engines, mechanical equipment, etc., can solve the problems of vehicle space occupied by the braking system, low controllability of braking efficiency, and reduced braking efficiency, etc., to achieve reduction Automobile accessories, ease of repair and replacement, effect of quantity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

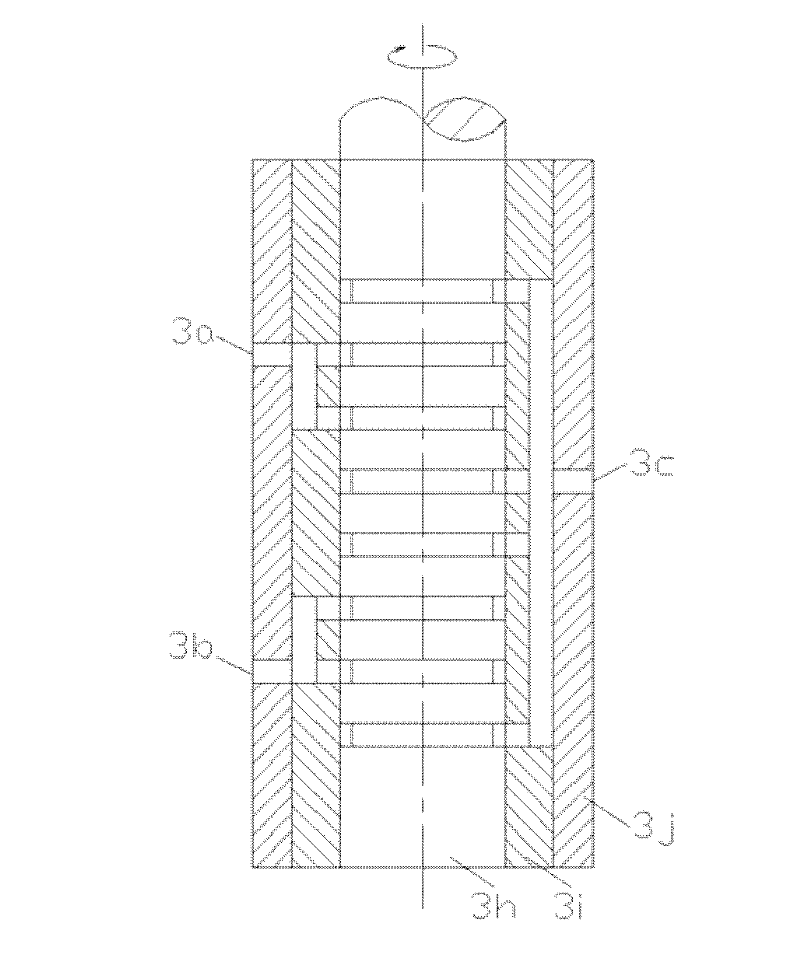

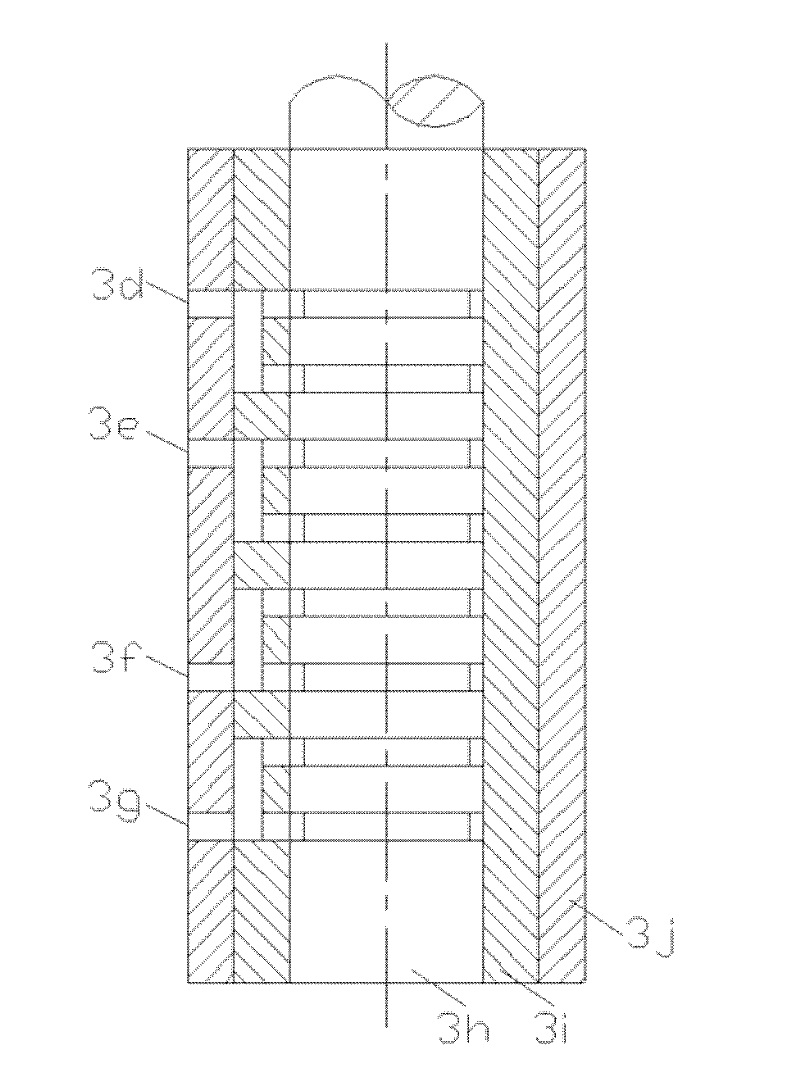

[0027] The present invention is illustrated by taking the system of the 1-2-4-3 type naturally aspirated internal combustion engine that adopts the intake as the row and the row as the advance braking mode as an example, and it is this system unless otherwise specified.

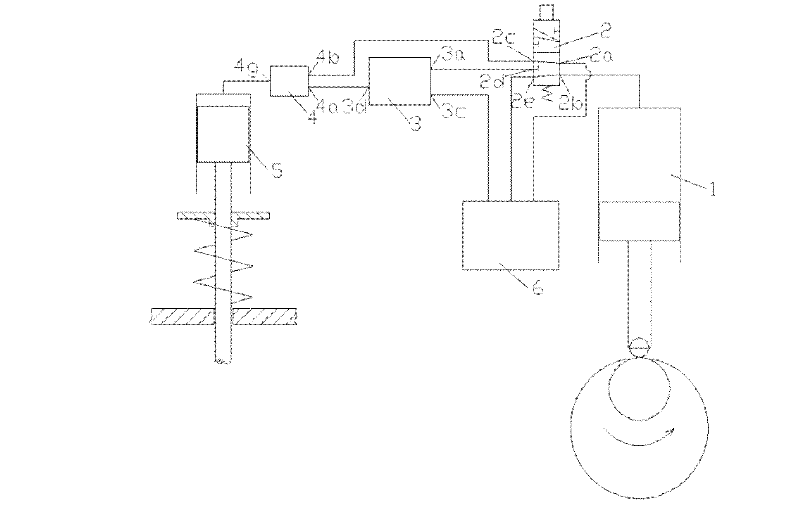

[0028] figure 1 A schematic diagram of a single-valve dual-mode fully variable valve drive system is shown. Due to the design characteristics of this system, the operation of the valve driver 5 is determined by the movement rules of the forward oil supply device 1 and the driving circulator 3, as well as the working status of the mode switch 4 and the forward high-speed valve 2. According to the working state of the mode switcher 4, the working process of the valve driver 5 can be divided into a driving mode and a braking mode, and the working process is as follows:

[0029] (1) Drive mode

[0030] When the internal combustion engine is in the driving mode as the power source, the mode switcher 4 is not dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com